At a fundamental level, molybdenum disilicide (MoSi2) heating elements are categorized by their physical shape and configuration to suit different furnace designs. The most common types are U-shaped, W-shaped (also known as multi-shank), and straight rod elements. These can also be produced in various special or custom-made forms for specific, complex heating applications.

While the physical shape is the most visible difference, the true challenge is selecting an element that aligns with your furnace's thermal profile, atmosphere, and maintenance strategy. The unique properties of MoSi2—its exceptional high-temperature capability in air and its brittleness at room temperature—dictate both its design and its handling.

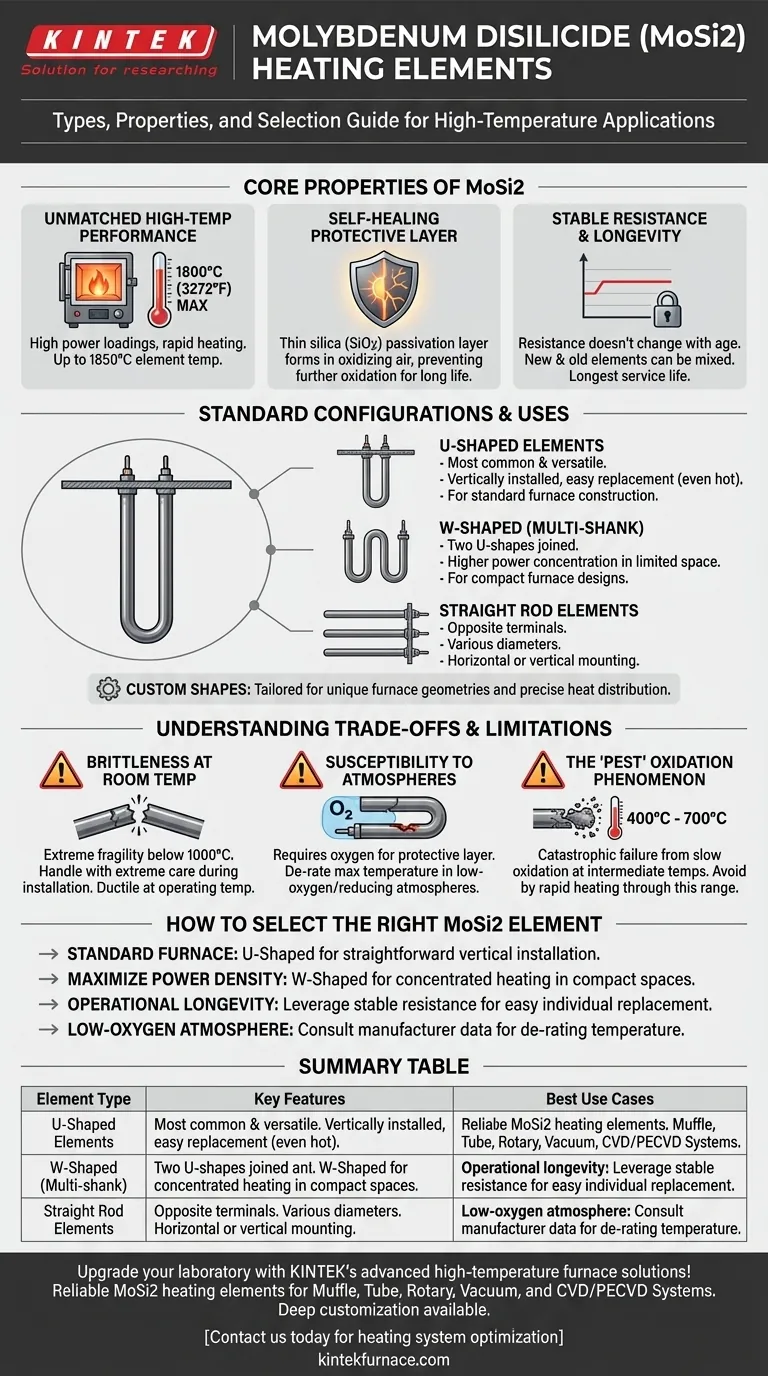

The Core Properties of MoSi2 Elements

To select the right type, you must first understand the material itself. MoSi2 is a ceramic-metallic composite prized for its performance in the most demanding environments.

Unmatched High-Temperature Performance

Molybdenum disilicide elements are renowned for their ability to operate at extremely high furnace temperatures, typically up to 1800°C (3272°F), with some grades reaching element temperatures of 1850°C.

They can handle very high power (watt) loadings, allowing for rapid furnace heating.

The Self-Healing Protective Layer

In an oxidizing atmosphere (like air), MoSi2 develops a thin, non-conductive surface layer of silica (SiO2). This passivation layer protects the element from further oxidation and is the key to its long life at high temperatures.

Stable Resistance and Longevity

Unlike many other metallic elements, the electrical resistance of MoSi2 does not change with age or use. This stability is a significant advantage, as it means new and old elements can be connected in the same circuit without issue.

This property, combined with its oxidation resistance, gives MoSi2 the longest inherent service life of any electric heating element.

Standard Configurations and Their Uses

The shape of an MoSi2 element is driven entirely by the design of the furnace and how heat needs to be distributed.

U-Shaped Elements

The U-shape is the most common and versatile configuration. It is typically installed vertically, hanging down from the furnace roof, with both electrical terminals on top.

This design is simple, robust, and easy to replace, even while the furnace is still hot.

W-Shaped (Multi-Shank) Elements

A W-shaped or multi-shank element is essentially two U-shapes joined together. Its primary purpose is to provide a higher concentration of heating power in a specific area.

These are often used in compact furnace designs where maximizing power density is critical.

Straight Rod Elements

Straight elements are used when furnace design requires terminals on opposite sides. They can be mounted horizontally or vertically. These are often manufactured in different diameters for the "hot zone" and the cooler terminal sections.

Custom and Special Shapes

For highly specialized equipment, such as laboratory furnaces with unique chamber geometries, manufacturers can produce custom shapes. This ensures optimal heat distribution and uniformity for the specific application.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging the limitations of MoSi2 is critical for successful implementation and avoiding costly failures.

Brittleness at Room Temperature

The single greatest challenge with MoSi2 is its extreme brittleness below 1000°C. The elements are rigid and fragile, like glass, when cool.

They must be handled with extreme care during shipping, unpacking, and installation to avoid fractures. Once at operating temperature, they become more ductile and less susceptible to mechanical shock.

Susceptibility to Specific Atmospheres

The protective silica layer requires oxygen to form and maintain itself. In low-oxygen or reducing atmospheres, this layer cannot form properly, leading to accelerated degradation of the element.

If operating in such an atmosphere, the element's maximum temperature must be significantly lowered according to manufacturer specifications.

The "Pest" Oxidation Phenomenon

At intermediate temperatures, typically between 400°C and 700°C, MoSi2 can be subject to a catastrophic failure mode known as pesting. This occurs when slow oxidation disintegrates the material into a powder.

This is generally avoided by heating rapidly through this temperature range, which is standard practice for furnaces using these elements.

How to Select the Right MoSi2 Element

Your choice should be guided by your specific operational goals and furnace design.

- If your primary focus is standard furnace construction: U-shaped elements offer the most straightforward and widely used solution for vertical installation.

- If your primary focus is maximizing power density: W-shaped (multi-shank) elements concentrate more heating power in a confined space for compact designs.

- If your primary focus is operational longevity: Leverage MoSi2's stable resistance by replacing individual elements as needed without having to match the resistance of a full set.

- If you are operating in a low-oxygen atmosphere: You must consult manufacturer data to de-rate the element's maximum temperature to prevent premature failure.

Understanding these material properties and configurations empowers you to design and maintain a more reliable and efficient high-temperature heating system.

Summary Table:

| Element Type | Key Features | Best Use Cases |

|---|---|---|

| U-Shaped | Versatile, easy to install and replace, hangs vertically | Standard furnace construction, general high-temperature applications |

| W-Shaped (Multi-Shank) | High power density, compact design | Maximizing heating in confined spaces, compact furnaces |

| Straight Rod | Terminals on opposite sides, variable diameters | Horizontal or vertical mounting in specific furnace designs |

| Custom Shapes | Tailored to unique geometries | Specialized applications requiring precise heat distribution |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable MoSi2 heating elements, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for enhanced efficiency and longevity. Contact us today to discuss how we can optimize your heating system!

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the temperature range for MoSi2 heating elements? Maximize Lifespan in High-Temp Applications

- What are the primary applications of MoSi2 heating elements in research? Achieve Reliable High-Temp Control for Material Synthesis

- What are the advantages of using molybdenum-disilicide heating elements for aluminum alloy processing? (Rapid Heating Guide)

- What role do MoSi2 heating elements play in 1500 °C experiments? Key to Stability and Precision

- What ceramic materials are commonly used for heating elements? Discover the Best for Your High-Temp Needs