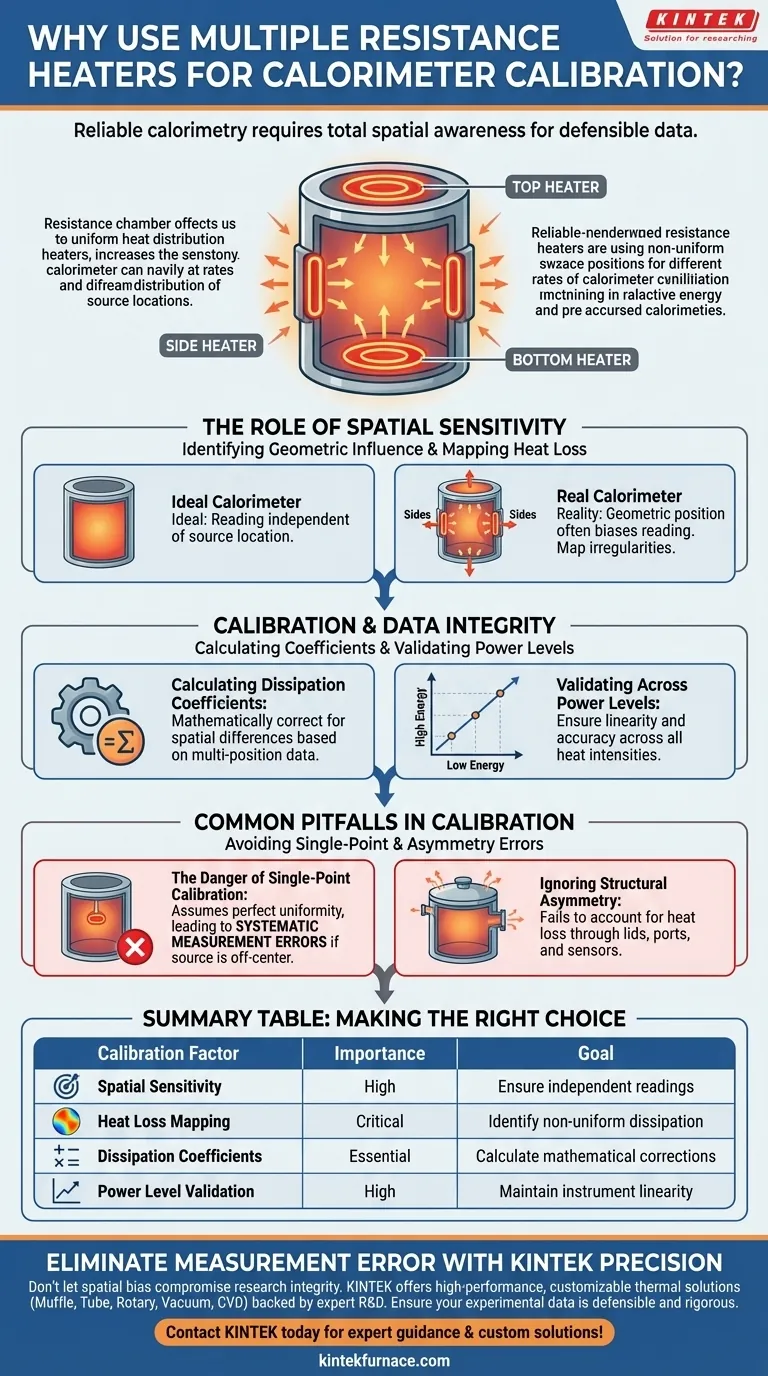

Reliable calorimetry requires total spatial awareness. Multiple sets of resistance heaters are strategically positioned—at the top, bottom, and sides of the chamber—during calibration to evaluate the device's spatial sensitivity. This ensures that the measurement results depend solely on the amount of heat generated, not on the geometric location of the heat source within the chamber.

By testing various locations, engineers can quantify the calorimeter's spatial sensitivity and map its heat loss distribution. This allows for the precise calibration of heat dissipation coefficients across different power levels, ensuring experimental data remains rigorous and reliable.

The Role of Spatial Sensitivity

Identifying Geometric Influence

In an ideal calorimeter, a specific amount of heat should yield the exact same reading regardless of where it originates inside the chamber.

However, in practice, the geometric position of the source often biases the reading.

By using heaters in varying positions, you verify whether the device measures heat differently at the top compared to the bottom or sides.

Mapping Heat Loss Distribution

Heat does not always escape a chamber uniformly.

Different areas of the calorimeter walls may conduct or radiate heat at slightly different rates.

Placing heaters in multiple positions allows you to map these irregularities and understand the specific heat loss distribution of the system.

Calibration and Data Integrity

Calculating Dissipation Coefficients

Once spatial differences are identified, the system must be mathematically corrected.

The data gathered from these multiple positions is used to calibrate heat dissipation coefficients.

This ensures that the final calculation accounts for how heat is lost from specific areas of the chamber, neutralizing errors caused by position.

Validating Across Power Levels

The relationship between heat source location and measurement error may change as the heat intensity increases.

The calibration process is not just about location; it evaluates these spatial factors across different power levels.

This ensures the instrument remains linear and accurate whether measuring a low-energy reaction or a high-energy event.

Common Pitfalls in Calibration

The Danger of Single-Point Calibration

A common mistake is calibrating a calorimeter using only a single heater placed in the geometric center.

This assumes perfect uniformity throughout the chamber, which is rarely physically possible.

If the actual experimental heat source is slightly off-center, a single-point calibration will lead to systematic measurement errors.

Ignoring Structural Asymmetry

Calorimeters often have lids, ports, or sensors that create thermal asymmetries.

Ignoring the "top" and "sides" during calibration fails to account for heat rising or escaping through structural gaps.

Comprehensive multi-position calibration exposes these weak points so they can be factored into the results.

Making the Right Choice for Your Goal

To ensure your experimental data is defensible, you must tailor your calibration approach to your accuracy requirements.

- If your primary focus is high-precision absolute measurement: Perform a full mapping calibration using heaters at the top, bottom, and sides to generate a comprehensive error correction matrix.

- If your primary focus is comparative analysis of fixed samples: Ensure the calibration heater is placed in the exact geometric position where your samples will sit to minimize relative error.

Ultimately, rigor in calibration defines the reliability of your data; assuming spatial uniformity is a risk, but measuring it is a certainty.

Summary Table:

| Calibration Factor | Importance | Goal |

|---|---|---|

| Spatial Sensitivity | High | Ensure readings are independent of heat source location |

| Heat Loss Mapping | Critical | Identify non-uniform heat dissipation through walls and lids |

| Dissipation Coefficients | Essential | Calculate mathematical corrections for thermal asymmetries |

| Power Level Validation | High | Maintain instrument linearity across high and low energy events |

Eliminate Measurement Error with KINTEK Precision

Don’t let spatial bias compromise your research integrity. KINTEK provides high-performance thermal solutions backed by expert R&D and manufacturing. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our laboratory high-temp furnaces are fully customizable to meet your specific calibration and heating needs.

Ensure your experimental data is defensible and rigorous. Our technical team is ready to help you design a system that guarantees absolute thermal uniformity.

Contact KINTEK today for expert guidance and custom solutions!

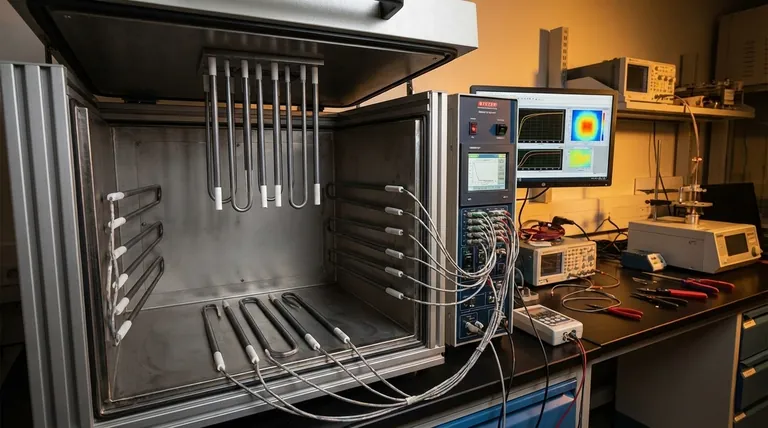

Visual Guide

References

- Tadahiko Mizuno, Jed Rothwell. Anomalous Heat Reaction from Hydrogen and Metals. DOI: 10.70923/001c.134027

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- What are the characteristics of molybdenum disilicide heating elements? Unlock High-Temp Performance

- What are the overall benefits of ceramic heating elements? Achieve Superior Durability, Efficiency, and Safety

- What are the key properties of silicon carbide that make it suitable for heating elements? Discover Its High-Temp Durability and Efficiency

- How does a graphite heater influence the thermal field? Optimize Silicon Crystal Quality with Precision Heating

- What factors should be considered when choosing between MoSi2 and SiC heating elements for sintering furnaces? Optimize Your Sintering Process

- Why are Silicon Carbide (SiC) heating elements and recrystallized alumina tubes used in vertical tube furnaces?

- What safety measures are incorporated into heating elements? Ensure Reliable Protection for Your Applications

- What are the monitoring responsibilities of a K-type thermocouple in a high-temp carbonization furnace? Expert Guide