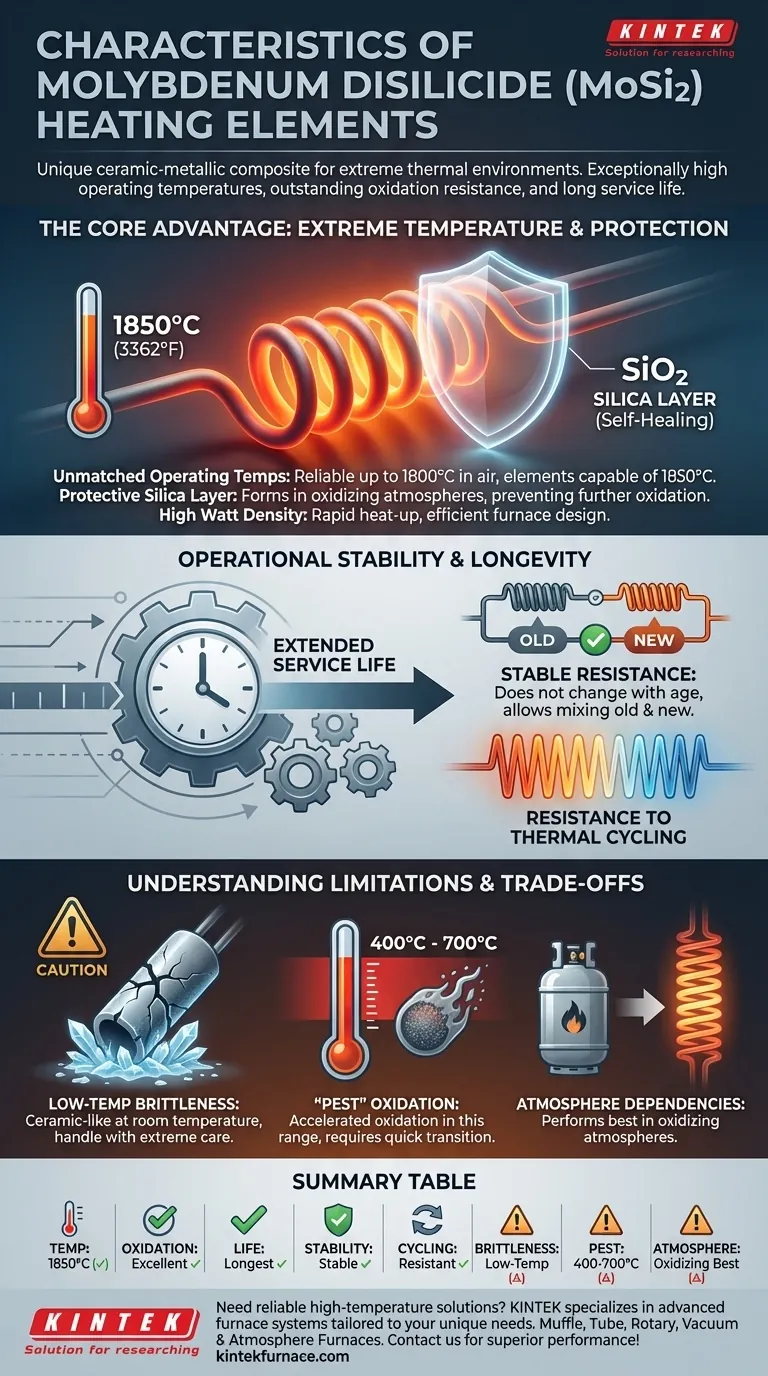

Fundamentally, molybdenum disilicide (MoSi2) heating elements are a unique ceramic-metallic composite designed for extreme thermal environments. Their defining characteristics are an exceptionally high operating temperature of up to 1850°C (3362°F), outstanding resistance to oxidation, and a remarkably long service life, making them a premier choice for the most demanding high-temperature industrial and laboratory furnaces.

While MoSi2 elements offer unparalleled temperature capabilities and longevity in oxidizing atmospheres, their primary limitation is significant brittleness at low temperatures, which dictates specific handling and operational protocols.

The Core Advantage: Extreme Temperature Performance

Molybdenum disilicide elements are engineered specifically for processes that other metallic elements cannot withstand. This capability stems from a unique combination of material properties.

Unmatched Operating Temperatures

MoSi2 elements are reliable for furnace temperatures up to 1800°C (3272°F), with the elements themselves capable of reaching 1850°C. This places them at the pinnacle of electric heating element technology for air-based applications.

The Protective Silica (SiO2) Layer

The key to their high-temperature survival is the formation of a thin, self-healing layer of silica (SiO2), or glass, on the element's surface. In an oxidizing atmosphere, this passivation layer forms and prevents the underlying material from further oxidation, even at extreme heat.

High Watt Density and Efficiency

These elements support very high watt loadings. This allows for rapid furnace heat-up times and enables furnace designs to achieve high temperatures without being overcrowded with elements, improving thermal uniformity and efficiency.

Operational Stability and Longevity

Beyond just temperature, MoSi2 elements are valued for their predictable and durable performance over time, which reduces maintenance and improves process consistency.

Stable Resistance Over Time

Unlike many heating elements, the electrical resistance of MoSi2 does not change significantly with age or use. This stability is a critical advantage, as it allows for new elements to be connected in series with old ones without issue.

Resistance to Thermal Cycling

MoSi2 elements can endure fast thermal cycling—rapid heating and cooling—without suffering from the degradation or fatigue that can damage other types of elements. This makes them ideal for processes that do not run continuously.

Extended Service Life

Due to their robust resistance to oxidation and thermal stress, MoSi2 elements possess the longest inherent service life of all common electric heating element types, providing exceptional long-term value.

Understanding the Trade-offs and Limitations

To use MoSi2 elements effectively, it is crucial to understand their specific weaknesses. These are not general-purpose heaters, and misapplication can lead to premature failure.

Low-Temperature Brittleness

The most significant limitation of MoSi2 is that it is extremely brittle at room temperature, behaving much like a ceramic. Elements must be handled with great care during installation and are susceptible to fracture from mechanical shock or vibration when the furnace is cold.

Susceptibility to "Pest" Oxidation

In a specific temperature range, typically between 400°C and 700°C, the protective silica layer does not form effectively. If an element is held in this range for extended periods, it can lead to a catastrophic form of accelerated oxidation known as "pest" oxidation, which can cause it to disintegrate. Furnaces should be designed to move through this temperature zone quickly.

Atmosphere Dependencies

MoSi2 elements perform best in oxidizing atmospheres where the protective silica layer can form and regenerate. Their use in reducing or other specific chemical atmospheres requires careful analysis, as certain compounds can attack the element or prevent the formation of the protective layer.

Making the Right Choice for Your Application

Selecting a heating element requires matching its characteristics to your process goals. MoSi2 is a specialized tool for demanding jobs.

- If your primary focus is reaching temperatures above 1600°C in air: MoSi2 is often the only viable and most effective choice.

- If your primary focus is rapid cycling and long-term stability: The stable resistance and durability of MoSi2 make it ideal for high-use applications, even at lower temperatures where its longevity can justify the cost.

- If your process involves high mechanical shock or frequent cold handling: The inherent brittleness of MoSi2 demands careful furnace design and handling protocols to prevent element fracture.

By understanding both its exceptional high-temperature strength and its low-temperature fragility, you can effectively leverage Molybdenum Disilicide to achieve your most demanding thermal processing goals.

Summary Table:

| Characteristic | Description |

|---|---|

| Operating Temperature | Up to 1850°C (3362°F) |

| Oxidation Resistance | Excellent due to self-healing silica layer |

| Service Life | Longest among common electric heating elements |

| Watt Density | High, enabling rapid heat-up and efficiency |

| Resistance Stability | Stable over time, allows mixing old and new elements |

| Thermal Cycling | Resistant to fast heating and cooling |

| Brittleness | Brittle at low temperatures, requires careful handling |

| Pest Oxidation | Susceptible in 400-700°C range, avoid prolonged exposure |

| Atmosphere Suitability | Best in oxidizing atmospheres |

Need reliable high-temperature solutions for your lab? KINTEK specializes in advanced furnace systems tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with deep customization to meet specific experimental requirements. Enhance your thermal processing with our expertise—contact us today to discuss how we can optimize your setup for superior performance and efficiency!

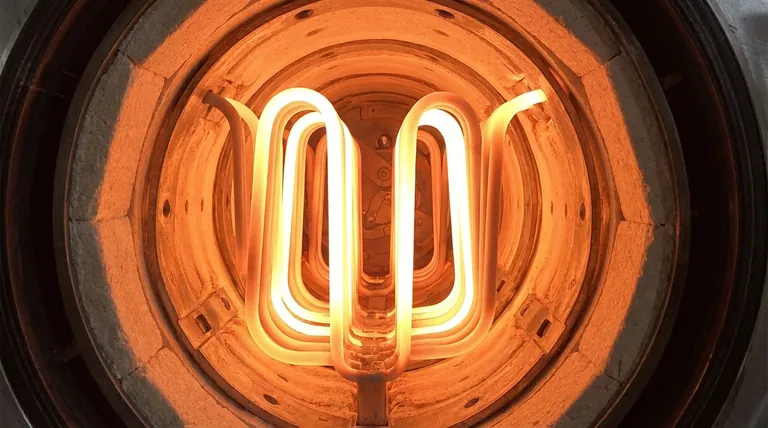

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing