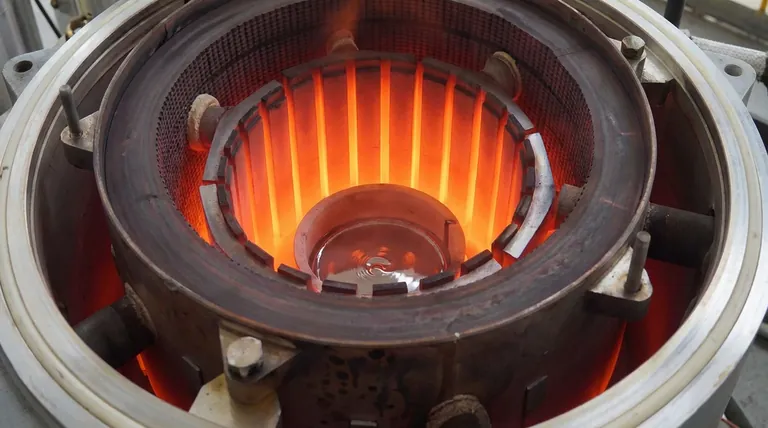

The graphite heater functions as the primary engine of thermal control within a single-crystal silicon furnace. Acting as the central power source via resistance heating, it does more than simply melt silicon; it establishes the specific thermal profile required to sustain stable crystal growth.

The graphite heater dictates the temperature gradient within the melt through precise power adjustment and design. This control is the deciding factor in managing crystallization rates, defining the shape of the solid-liquid interface, and preventing structural defects caused by thermal stress.

The Mechanism of Thermal Regulation

Generating the High-Temperature Environment

The furnace relies on resistance heating generated by the graphite component to achieve the extreme temperatures necessary for silicon processing.

Because the heater acts as the central power source, its ability to maintain consistent heat is the baseline requirement for the entire operation.

Shaping the Temperature Gradient

Beyond raw heat, the heater's design determines the temperature gradient across the silicon melt.

This gradient is not accidental; it is a calculated distribution of thermal energy that drives the direction and speed of solidification.

Impact on Crystal Quality

Managing Crystallization Rate

The precise regulation of power allows operators to control the crystallization rate of the silicon.

If the heat input fluctuates, the growth rate becomes unstable, potentially ruining the single-crystal structure.

Defining the Interface Shape

The heater’s distribution of heat directly sculpts the solid-liquid interface, the boundary where the crystal meets the melt.

Maintaining the correct interface shape is essential for uniform growth and material homogeneity.

Preventing Dislocation Defects

Improper heating leads to thermal stress within the growing crystal.

By ensuring a smooth and controlled thermal field, the graphite heater minimizes this stress, thereby preventing the formation of dislocation defects that compromise the silicon's electronic properties.

Understanding the Trade-offs of Heater Geometry

The Risk of Localized Hot Spots

The geometric structure of the heater significantly influences the electric and thermal field distribution.

Traditional tubular heaters often struggle with high surface loads, which can create local hot spots. These irregularities lead to radial temperature differences that can destabilize the melt.

Improving Uniformity with Plate Designs

In contrast, plate-shaped heaters are designed to increase the area available for radiation heat exchange.

This design reduces the surface heat flux density, resulting in superior temperature uniformity in the heating zone and extending the service life of the component.

Optimizing for Crystal Growth

To ensure the highest quality silicon production, you must match the heater's capabilities to your specific processing goals.

- If your primary focus is Defect Reduction: Prioritize a heater design that offers precise power adjustment to minimize thermal stress and prevent dislocations.

- If your primary focus is Thermal Uniformity and Longevity: Consider plate-shaped geometries to lower surface heat flux and eliminate radial temperature discrepancies.

The graphite heater is not just a heat source; it is the fundamental tool for architecting the internal environment of your furnace.

Summary Table:

| Feature | Impact on Thermal Field | Benefit for Crystal Growth |

|---|---|---|

| Power Regulation | Precise control of thermal gradient | Maintains stable crystallization rates |

| Heater Geometry | Influences heat flux density | Ensures radial temperature uniformity |

| Interface Shaping | Sculpts solid-liquid boundary | Improves material homogeneity |

| Stress Management | Minimizes thermal fluctuations | Prevents dislocation defects |

Elevate Your Crystal Production with KINTEK

Precise thermal field control is the difference between a high-yield harvest and a failed batch. At KINTEK, we specialize in the engineering of high-performance graphite components and advanced furnace systems tailored for the semiconductor industry.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside customizable high-temp lab furnaces designed to meet your unique processing needs. Whether you are aiming to reduce dislocation defects or extend heater longevity through optimized geometry, our team is ready to deliver the solution.

Ready to optimize your thermal profile? Contact KINTEK experts today to discuss your custom furnace requirements.

References

- Lei Jiang, Yue Zhao. A Soft Measurement Method for the Tail Diameter in the Growing Process of Czochralski Silicon Single Crystals. DOI: 10.3390/app14041569

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the standard dimensions for MoSi2 heating elements? Optimize Your Furnace Performance

- How do ceramic heaters differ from infrared heaters in terms of heating method? Choose the Right Heater for Your Space

- What are the characteristics and uses of molybdenum in heating elements? Unlock High-Temp Performance for Your Lab

- What function do 220V armored electric heaters serve in SA-178 Gr A steel pipe heat treatment? Expert Precision Heating

- What are the common types of heating element designs? Discover the Best Fit for Your Heating Needs

- What additional factors affect heater design requirements? Optimize Performance and Longevity

- What materials are typically used in the construction of high temperature heating elements? Discover the Best Options for Your Needs

- Why is the low thermal mass of MoSi2 heating elements beneficial? Achieve Rapid, Precise Temperature Control