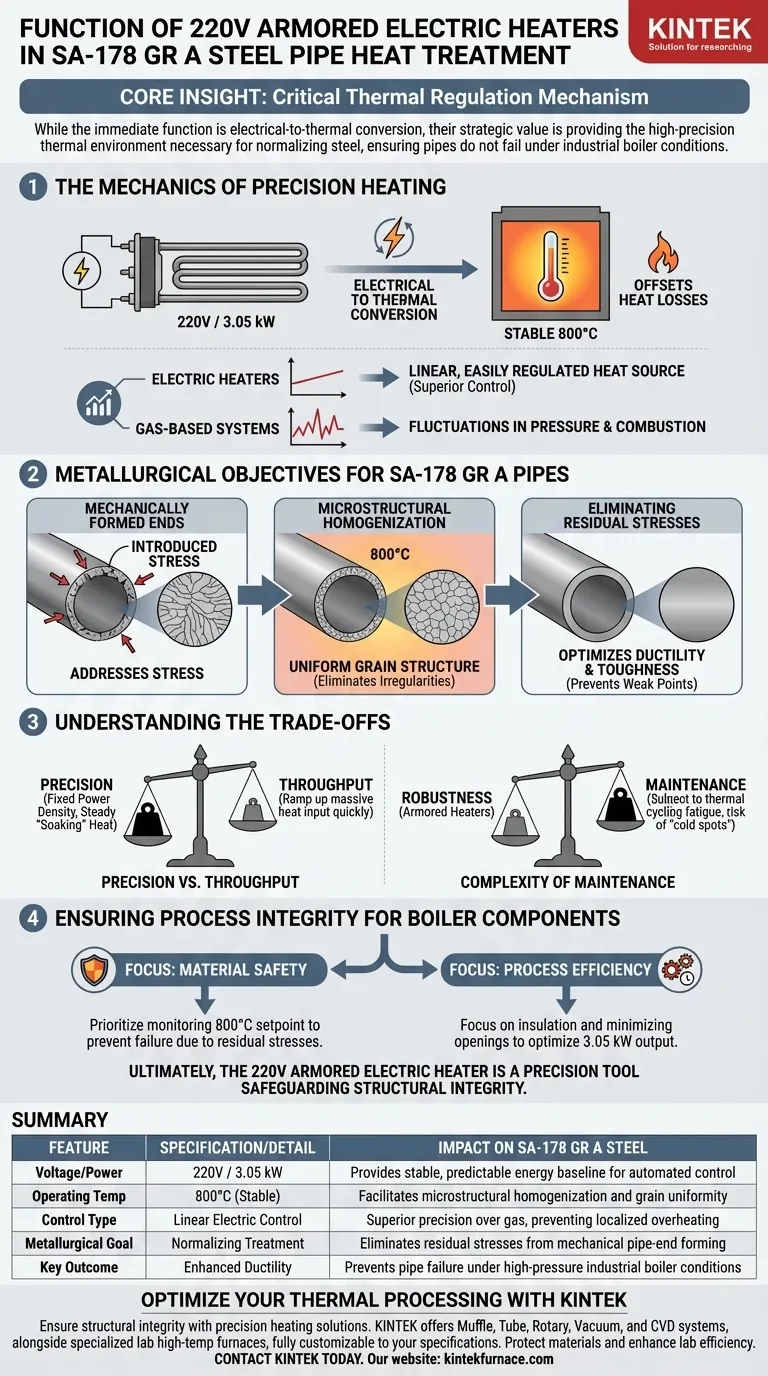

220V armored electric heaters serve as the critical thermal regulation mechanism for the precise heat treatment of SA-178 Gr A steel pipes. By converting electrical energy into thermal energy with specific outputs (such as 3.05 kW), these components actively offset heat losses to maintain a strictly stable operating temperature of 800°C.

Core Insight While the immediate function of these heaters is energy conversion, their strategic value lies in providing the high-precision thermal environment necessary for normalizing steel. Unlike gas-based systems, these heaters offer the stability required to achieve microstructural homogenization, ensuring the pipes do not fail under industrial boiler conditions.

The Mechanics of Precision Heating

Maintaining a Stable 800°C Environment

The primary technical function of the armored electric heater is to sustain a constant high-temperature environment.

Specifically, the process requires a steady operating temperature of 800°C. The heaters are engineered to continuously compensate for thermal energy lost to the surrounding environment during the treatment cycle.

Electrical to Thermal Conversion

These units function by converting electrical input directly into thermal energy.

With specific power ratings, such as 3.05 kW, they provide a consistent energy baseline. This predictable output is essential for automating the temperature control loop within industrial electric furnaces.

Superior Control Compared to Gas

A key advantage of using armored electric heaters over traditional gas-based heating is control precision.

Gas systems can suffer from fluctuations in fuel pressure or combustion consistency. Electric heaters provide a linear, easily regulated heat source, which is mandatory when the margin for error in the steel's temperature profile is narrow.

Metallurgical Objectives for SA-178 Gr A Pipes

Addressing Mechanically Formed Ends

The heat treatment specifically targets the ends of SA-178 Gr A steel pipes, which have undergone mechanical forming.

This mechanical forming introduces stress into the material structure. The heaters enable a "normalizing" heat treatment designed to address these specific localized changes.

Microstructural Homogenization

The ultimate goal of maintaining the 800°C temperature is microstructural homogenization.

By holding the steel at this precise temperature, the internal grain structure of the metal becomes uniform. This eliminates the irregularities caused by previous mechanical processing.

Eliminating Residual Stresses

The controlled heating process effectively relieves residual internal stresses.

If left untreated, these stresses creates weak points in the pipe. Removing them is critical for optimizing the ductility and toughness of the steel.

Understanding the Trade-offs

Precision vs. Energy Throughput

While armored electric heaters offer superior precision, they are generally limited by their fixed power density (e.g., 3.05 kW).

Unlike gas burners which can ramp up massive heat input quickly, electric heaters provide steady, "soaking" heat. They are excellent for maintaining temperature but may have slower recovery times if the furnace door is opened frequently or if the thermal load increases unexpectedly.

Complexity of Element Maintenance

Armored heaters are robust, but they are subject to thermal cycling fatigue.

Maintaining the strict 800°C requirement means the elements must be functioning at peak efficiency. A degrading heating element can create "cold spots" in the furnace, potentially leading to uneven heat treatment and inconsistent pipe quality.

Ensuring Process Integrity for Boiler Components

To ensure the safety and longevity of industrial boilers, the application of these heaters must be aligned with your specific processing goals.

- If your primary focus is Material Safety: Prioritize the monitoring of the 800°C setpoint, as deviations here prevent the elimination of residual stresses that lead to pipe failure.

- If your primary focus is Process Efficiency: Focus on insulation and minimizing furnace openings to allow the 3.05 kW output to offset natural losses rather than reheating the air.

Ultimately, the 220V armored electric heater is not just a heat source; it is a precision tool that safeguards the structural integrity of high-pressure boiler components.

Summary Table:

| Feature | Specification/Detail | Impact on SA-178 Gr A Steel |

|---|---|---|

| Voltage/Power | 220V / 3.05 kW | Provides stable, predictable energy baseline for automated control |

| Operating Temp | 800°C (Stable) | Facilitates microstructural homogenization and grain uniformity |

| Control Type | Linear Electric Control | Superior precision over gas, preventing localized overheating |

| Metallurgical Goal | Normalizing Treatment | Eliminates residual stresses from mechanical pipe-end forming |

| Key Outcome | Enhanced Ductility | Prevents pipe failure under high-pressure industrial boiler conditions |

Optimize Your Thermal Processing with KINTEK

Ensure the structural integrity of your high-pressure components with precision heating solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized lab high-temp furnaces.

Whether you need to maintain a strict 800°C environment or require a custom thermal setup for unique metallurgical needs, our systems are fully customizable to your specifications. Protect your materials and enhance your lab's efficiency—contact KINTEK today to discuss your custom furnace requirements.

Visual Guide

References

- Gustavo Ribeiro Zanini, LUIS CARLOS GERON. PROJETO DE UM FORNO ELÉTRICO INDUSTRIAL PARA TRATAMENTO TÉRMICO TUBOS DE AÇO SA-178 GR A. DOI: 10.52138/citec.v17i01.437

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What makes Nichrome 80/20 alloy wire suitable for heating elements at 800°C? Expert Insights on Durability

- What are the two most commonly used heating elements in modern sintering furnaces? Choose MoSi2 or SiC for High-Temp Success

- How are heating elements designed? Master the Balance of Heat Generation and Dissipation

- What are the primary benefits of quartz tubes in high-temperature applications? Achieve Precision and Purity in Extreme Heat

- Why are silicon carbide heating elements suitable for high-temperature applications? Discover Their Key Benefits

- What temperature can ceramic infrared heaters reach? Unlock Efficient Heating for Your Materials

- How has molybdenum been used in industrial furnaces as a heating element? Unlock High-Temp Performance Up to 1900°C

- What is a key property of silicon carbide as a ceramic material? Discover Its High-Temp and Thermal Conductivity Edge