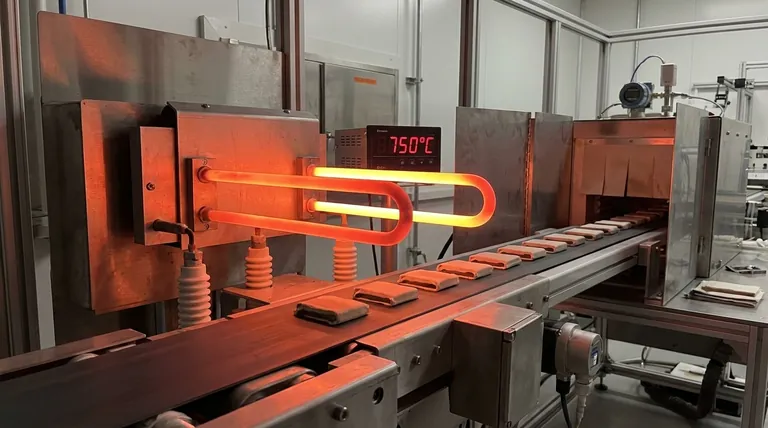

At its peak, a ceramic infrared heater can achieve a surface temperature exceeding 750°C (1382°F). This high temperature is not just for creating warmth; it's fundamental to the heater's ability to generate a specific and highly effective type of radiant energy. Understanding this allows you to move beyond simply heating a space or object and begin controlling a precise industrial or commercial process.

The maximum temperature of a ceramic heater is a critical detail, but the real takeaway is how this temperature dictates the wavelength of the infrared energy it produces. This wavelength determines which materials the heater can heat most efficiently, making it a specialized tool for specific jobs.

How Ceramic Heaters Achieve High Temperatures

A ceramic heater’s design is simple yet highly effective, built around two core components working in tandem to convert electricity into targeted infrared energy.

The Core Mechanism: Resistance Heating

At the heart of the heater is a high-resistance conductor, typically a nickel-chrome (NiCr) alloy. When a high amperage electrical current is passed through this coil, its inherent resistance causes it to become extremely hot, much like the element in a toaster.

The Role of the Ceramic Body

This heating coil is embedded directly within a solid ceramic body. The ceramic material absorbs the intense heat from the coil and, due to its excellent properties as a thermal emitter, radiates that energy away from its surface.

The ceramic is the key to the heater's function. It acts as a perfect "blackbody" emitter, efficiently converting the conductive heat from the coil into radiative infrared energy.

Temperature Determines Energy Wavelength

The 750°C surface temperature is what allows the heater to primarily emit long-wave infrared radiation (typically in the 2 - 10 micron range). This is a fundamental principle of physics: the temperature of an object dictates the peak wavelength of the energy it radiates. A cooler object emits longer waves, while a hotter object emits shorter, more intense waves.

What a 750°C Temperature Means for Application

This specific temperature and its resulting long-wave output are what make ceramic heaters uniquely suited for certain tasks and less ideal for others.

Matched for Organic Materials and Plastics

Many common materials, including water, plastics (like PVC and PET), and most organic substances, have a peak absorption spectrum that falls directly within the long-wave infrared range. This means a ceramic heater's energy is absorbed deeply and efficiently by the material itself, rather than just heating the air around it or scorching the surface. This makes them ideal for:

- Curing paints and water-based coatings

- Thermoforming plastic sheets

- Drying food products or textiles

A "Gentle" and Uniform Heat Source

Compared to short-wave heaters (like halogen), which can operate at over 2200°C, the energy from a ceramic element is less intense. This allows for a more uniform and gentle heating process, preventing surface damage and ensuring the material heats through evenly.

Significant Thermal Mass

The solid ceramic body that makes the heater so effective also gives it high thermal mass. It stores a significant amount of heat. This means it heats the target object or area consistently, even with minor fluctuations in voltage or ambient air movement.

Understanding the Trade-offs

No heating technology is perfect for every scenario. The properties that make ceramic heaters effective also introduce clear limitations.

Slow Heat-Up and Cool-Down

The high thermal mass means a ceramic heater takes several minutes to reach its optimal operating temperature. Likewise, it continues to radiate heat for a considerable time after being switched off.

This makes it unsuitable for processes that require rapid on/off cycling or immediate temperature changes.

Durability and Installation

While the elements are generally robust and resistant to vibration and contamination, the ceramic material itself can be brittle. It can be damaged by direct impact. Furthermore, the high surface temperature necessitates careful installation with proper clearance from other materials and often requires safety guards to prevent accidental contact.

Making the Right Choice for Your Goal

The ideal heater depends entirely on what you need to accomplish. The key is to match the heater's output wavelength to the absorption properties of the material you are heating.

- If your primary focus is process heating for plastics, food, or water-based coatings: A ceramic heater is an excellent choice, as its long-wave output ensures efficient and uniform energy absorption.

- If your primary focus is a process requiring very fast heat-up and cool-down cycles: You should consider a quartz or halogen heater, as a ceramic element's thermal inertia is a significant disadvantage here.

- If your primary focus is zoned comfort heating in a large, open space: A ceramic heater is highly effective, but its high surface temperature requires professional installation and careful safety considerations.

Understanding the relationship between temperature and wavelength empowers you to select a precise tool, not just a generic heater.

Summary Table:

| Aspect | Details |

|---|---|

| Max Temperature | Exceeds 750°C (1382°F) |

| Infrared Wavelength | Long-wave (2-10 microns) |

| Key Applications | Curing paints, thermoforming plastics, drying food/textiles |

| Pros | Efficient for organic materials, uniform heating, high thermal mass |

| Cons | Slow heat-up/cool-down, brittle ceramic, requires safety measures |

Need a custom high-temperature furnace for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs—contact us today to enhance your process efficiency!

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the advantages of using molybdenum-disilicide heating elements for aluminum alloy processing? (Rapid Heating Guide)

- What role do MoSi2 heating elements play in 1500 °C experiments? Key to Stability and Precision

- What is the temperature range where MoSi2 heating elements should not be used for long periods? Avoid 400-700°C to Prevent Failure

- What are the primary applications of Molybdenum Disilicide (MoSi2) heating elements in furnaces? Achieve High-Temp Excellence

- What types of molybdenum disilicide heating elements are available? Choose the Right Element for Your High-Temp Needs