In high-temperature environments, quartz tubes are a benchmark material due to their remarkable combination of thermal stability, chemical inertness, and unique optical properties. They reliably operate at continuous temperatures up to 1200°C without significant deformation and resist attack from most acids and reactive gases, ensuring the integrity of the process and the purity of the sample within.

The true value of quartz is not just its ability to withstand heat, but its unique synergy of properties. This combination ensures process reliability, prevents sample contamination, and allows for direct observation, making it an indispensable tool for precision-controlled thermal applications.

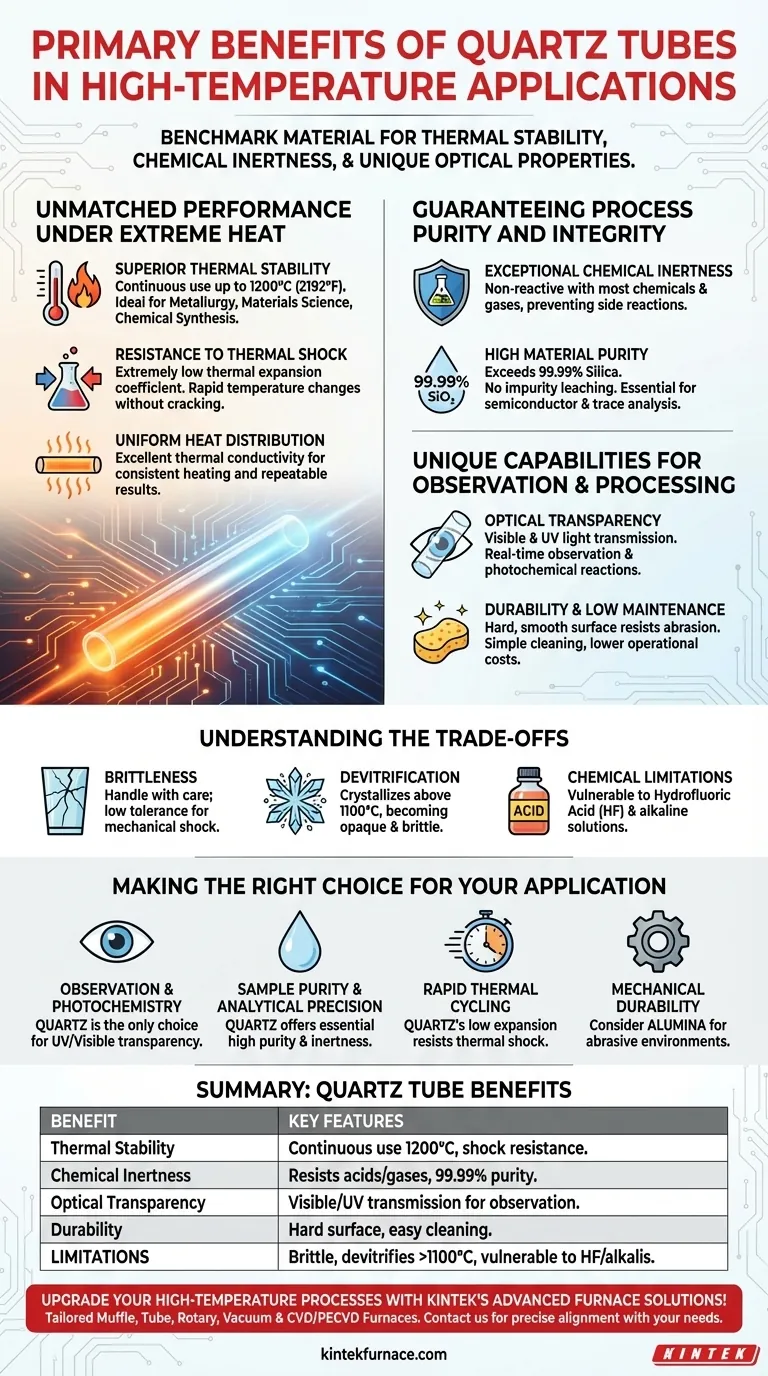

Unmatched Performance Under Extreme Heat

The primary function of a high-temperature tube is to provide a stable, contained environment. Quartz excels at this due to its fundamental material properties.

Superior Thermal Stability

Quartz tubes can sustain extremely high operating temperatures. Most grades are rated for continuous use up to 1200°C (2192°F), making them suitable for demanding processes in metallurgy, materials science, and chemical synthesis.

Resistance to Thermal Shock

A key differentiator for quartz is its extremely low coefficient of thermal expansion. This means it expands and contracts very little when heated or cooled.

This property gives it outstanding resistance to thermal shock, allowing for rapid temperature changes without cracking or shattering—a critical feature in furnace systems that require fast cycling.

Uniform Heat Distribution

Quartz exhibits excellent thermal conductivity, which allows heat to be distributed evenly across the tube's surface. This ensures uniform and consistent heating of the sample inside, which is vital for achieving predictable and repeatable experimental results.

Guaranteeing Process Purity and Integrity

In many scientific and industrial processes, preventing contamination is just as important as managing temperature. The composition of quartz makes it ideal for applications demanding high purity.

Exceptional Chemical Inertness

Fused quartz is highly non-reactive and will not corrode or react with the vast majority of chemicals and process gases, even at elevated temperatures. This inertness is crucial for preventing unwanted side reactions and ensuring the final product is not contaminated.

High Material Purity

Quartz tubes are manufactured from high-purity silica, often exceeding 99.99% SiO₂. This inherent purity ensures that the tube itself does not leach impurities into the sample or process atmosphere, a non-negotiable requirement for semiconductor manufacturing and trace-element analysis.

Unique Capabilities for Observation and Processing

Beyond its thermal and chemical resilience, quartz offers unique features that enable applications other materials cannot support.

Optical Transparency

Unlike opaque ceramics, quartz is transparent to a wide spectrum of light, including visible and ultraviolet (UV) wavelengths. This allows for direct, real-time observation of processes like pyrolysis or crystal growth inside the furnace.

This transparency also enables photochemical reactions, where UV light is used to initiate or influence a process within the heated environment.

Durability and Low Maintenance

The hard, smooth surface of a quartz tube is highly resistant to abrasion and minimizes the buildup of residue. This makes cleaning simpler and more effective, reducing downtime and lowering long-term operational costs.

Understanding the Trade-offs

While quartz is an exceptional material, it is not universally perfect. Acknowledging its limitations is key to proper application.

Brittleness

Like any glass, quartz is hard but brittle. It has low tolerance for mechanical shock or impact and must be handled with care to prevent chipping or catastrophic failure. It is not suitable for applications involving high mechanical stress or vibration.

Devitrification

When held at very high temperatures (typically above 1100°C) for extended periods, quartz can begin to devitrify. This process involves the amorphous glass structure crystallizing, which makes it opaque, reduces its strength, and increases its susceptibility to thermal shock.

Chemical Limitations

While highly inert, quartz is vulnerable to a few specific substances. It will be etched by hydrofluoric acid (HF) and can be damaged by hot phosphoric acid and alkaline solutions. These incompatibilities must be considered during process design.

Making the Right Choice for Your Application

Selecting the right material depends entirely on your primary objective. Use these guidelines to determine if quartz fits your needs.

- If your primary focus is process monitoring or photochemistry: The unparalleled optical transparency of quartz to visible and UV light makes it the only logical choice.

- If your primary focus is sample purity and analytical precision: The combination of high material purity and chemical inertness in quartz is essential to prevent contamination.

- If your primary focus is rapid thermal cycling and stability: The extremely low thermal expansion of quartz provides the resistance to thermal shock that you need.

- If your primary focus is mechanical durability in an abrasive environment: You may want to consider a harder, opaque ceramic like alumina, which offers superior resistance to wear and mechanical stress.

By understanding these core properties and trade-offs, you can confidently select quartz for applications that demand precision, purity, and performance under heat.

Summary Table:

| Benefit | Key Features |

|---|---|

| Thermal Stability | Continuous use up to 1200°C, low thermal expansion for shock resistance |

| Chemical Inertness | Resists most acids and gases, high purity (99.99% SiO₂) |

| Optical Transparency | Allows visible and UV light transmission for real-time observation |

| Durability | Hard surface, easy to clean, low maintenance |

| Limitations | Brittle, devitrifies above 1100°C, vulnerable to HF and alkalis |

Upgrade your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing purity, efficiency, and reliability. Contact us today to discuss how we can support your specific applications and drive your innovations forward!

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a vacuum-sealed quartz tube in MnBi2Te4 growth? Ensure High-Purity Crystal Synthesis

- What is the working principle of a vacuum tube furnace? Master Precise High-Temperature Processing

- What is the significance of porcelain furnaces in academic and scientific research? Unlock Innovation with Precise High-Temperature Control

- What industrial and research applications are tube furnaces used for? Unlock Precise Thermal Processing Solutions

- What role do tube furnaces play in semiconductor and battery production? Unlock Precision in High-Temp Processing