At its core, silicon carbide (SiC) heating elements are suitable for high-temperature applications due to a unique combination of properties. They can withstand extreme operating temperatures, possess high thermal conductivity for rapid heating, and are exceptionally durable, resisting both physical stress and chemical corrosion over long periods of service.

The choice of a heating element is never about a single attribute, but about the balance of performance, longevity, and operational environment. Silicon carbide excels because it offers a robust, all-around solution for a wide range of demanding industrial heating processes, especially those performed in air.

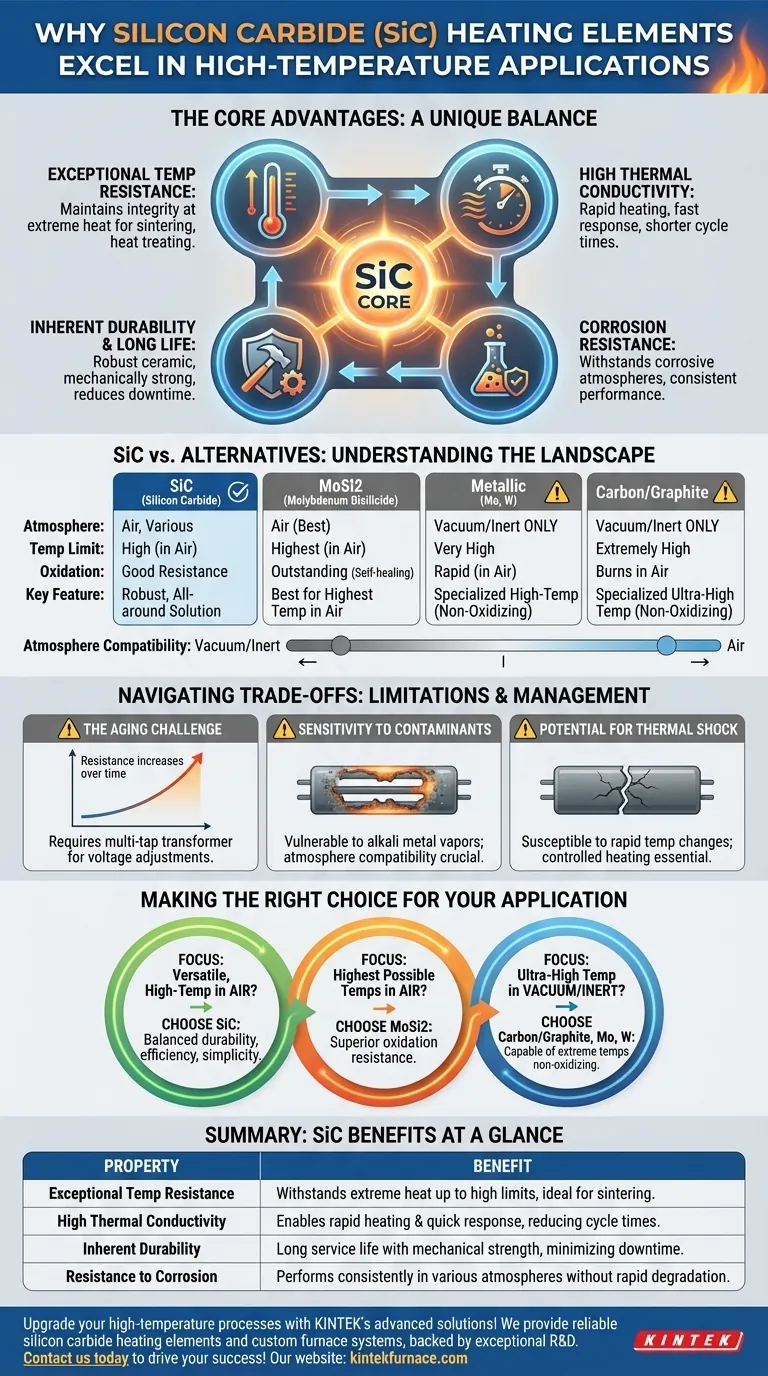

The Core Properties of Silicon Carbide

To understand why SiC is a default choice for many high-temperature furnaces, we must look at its specific material characteristics. Each property solves a distinct industrial challenge.

Exceptional Temperature Resistance

Silicon carbide elements are engineered to endure constant, extreme heat. They maintain their structural integrity and performance at temperatures where many metallic elements would fail, making them ideal for processes like sintering, heat treating, and melting non-ferrous metals.

High Thermal Conductivity

This property allows the elements to transfer heat energy very efficiently. In practical terms, this means furnaces can reach their target temperature quickly and respond rapidly to control inputs, leading to shorter cycle times and improved productivity.

Inherent Durability and Long Service Life

SiC is a very hard, mechanically strong ceramic material. This physical robustness translates to a long operational lifespan, reducing the frequency of costly downtime and element replacement compared to more fragile alternatives.

Resistance to Corrosion

Many high-temperature processes involve atmospheres that can be corrosive to heating elements. SiC offers good resistance to chemical attack, allowing it to provide consistent performance in a variety of process environments without rapid degradation.

How SiC Compares to Other High-Temperature Materials

Silicon carbide is not the only option for high-temperature heating. Understanding its position relative to other materials clarifies where it provides the most value.

vs. Molybdenum Disilicide (MoSi2)

MoSi2 elements are another premier choice for high-temperature applications. They are known for forming a protective, self-healing layer of silica (SiO2) above 1000°C, which gives them outstanding oxidation resistance. MoSi2 can often reach higher operating temperatures in air than SiC.

vs. Metallic Elements (Molybdenum, Tungsten)

Pure metallic elements like molybdenum and tungsten are used for very high-temperature processes, such as sintering and hardening. However, they oxidize rapidly and must be operated in a vacuum or a protective, inert atmosphere, which adds significant complexity and cost to the furnace design. SiC, by contrast, can operate directly in air.

vs. Carbon/Graphite

Graphite elements can achieve extremely high temperatures, but like molybdenum and tungsten, they require a vacuum or inert atmosphere to prevent them from burning away in the presence of oxygen. They are reserved for specialized, non-oxidizing environments.

Understanding the Trade-offs

No material is without its limitations. Acknowledging the trade-offs associated with silicon carbide is critical for proper application and management.

The Challenge of Aging

The most significant operational characteristic of SiC is that its electrical resistance gradually increases over time with use. This "aging" process requires a power supply system (typically a multi-tap transformer) that can deliver progressively higher voltage to maintain the required power output.

Sensitivity to Contaminants

While generally robust, SiC elements can be attacked by certain chemical vapors, particularly those containing alkali metals, which can accelerate degradation and lead to premature failure. The process atmosphere must be compatible with the element.

Potential for Thermal Shock

Although SiC has good thermal conductivity, it is still a ceramic and can be susceptible to fracture if subjected to extremely rapid, uncontrolled temperature changes. Proper furnace programming and control are essential to prevent thermal shock.

Making the Right Choice for Your Application

Selecting the optimal heating element requires you to align the material's properties with the specific goals of your thermal process.

- If your primary focus is versatile, high-temperature heating in air: Silicon carbide is often the most balanced and reliable choice, offering a great mix of durability, efficiency, and operational simplicity.

- If your primary focus is achieving the highest possible temperatures in an air atmosphere: Molybdenum disilicide (MoSi2) is typically superior due to its exceptional oxidation resistance and self-healing properties.

- If your primary focus is ultra-high temperature processing in a vacuum or inert gas: Graphite, molybdenum, or tungsten elements are the necessary choice, as they are capable of reaching temperatures that other elements cannot but require a non-oxidizing environment.

Ultimately, choosing the right element is a matter of matching its capabilities to the precise demands of your temperature, atmosphere, and production cycle.

Summary Table:

| Property | Benefit |

|---|---|

| Exceptional Temperature Resistance | Withstands extreme heat up to high limits, ideal for sintering and heat treating |

| High Thermal Conductivity | Enables rapid heating and quick response, reducing cycle times |

| Inherent Durability | Long service life with mechanical strength, minimizing downtime |

| Resistance to Corrosion | Performs consistently in various atmospheres without rapid degradation |

Upgrade your high-temperature processes with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable silicon carbide heating elements and custom furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and performance. Contact us today to discuss how we can support your specific applications and drive your success!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality