At its core, Silicon Carbide (SiC) is a high-performance ceramic material used for heating elements that excel in applications demanding extreme temperatures, structural rigidity, and chemical resistance. Capable of operating reliably at temperatures up to 1600°C (2912°F), SiC elements are defined by their ability to resist deformation, corrosion, and thermal shock in harsh industrial environments.

While its ability to operate at extreme temperatures is its most famous trait, the defining characteristic of a Silicon Carbide heating element is its gradual increase in electrical resistance over its lifespan—a process known as "aging"—which must be managed for consistent performance.

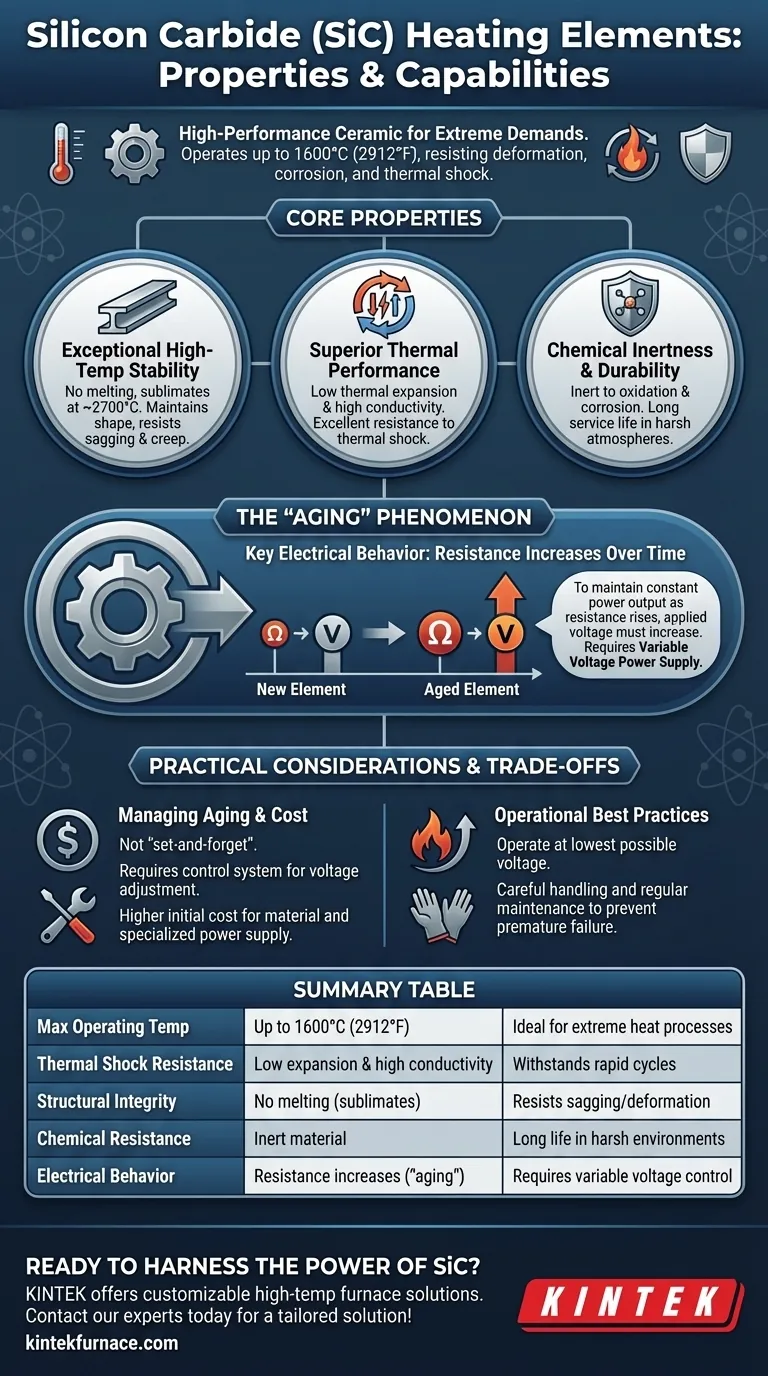

The Core Properties of Silicon Carbide Heaters

Silicon Carbide's unique combination of thermal, chemical, and structural properties makes it a premier choice for high-temperature industrial processes. These characteristics work in concert to deliver reliable and powerful heating.

Exceptional High-Temperature Stability

SiC does not melt at atmospheric pressure. Instead, it sublimates (turns from a solid directly to a gas) at around 2700°C, ensuring it maintains its shape far beyond its typical operating temperatures.

This means the elements do not sag, deform, or creep under their own weight, a common failure point for metallic elements at extreme heat. This structural integrity is critical in furnace and kiln design.

Superior Thermal Performance

SiC has a low coefficient of thermal expansion, which means it does not significantly change in size when heated or cooled. This property, combined with its high thermal conductivity, gives it excellent resistance to thermal shock.

As a result, SiC elements can be heated and cooled quickly without cracking, which is essential for industrial processes that require rapid temperature cycling.

Chemical Inertness and Durability

The material is chemically inert, making it highly resistant to both oxidation and corrosion from process atmospheres and chemical vapors. This inherent toughness contributes to a long service life.

Unlike some other materials, SiC elements perform well in reducing atmospheres, further expanding their range of use in specialized chemical and manufacturing processes.

Understanding the Key Electrical Behavior: "Aging"

The most important operational concept for SiC heating elements is not just their heat output, but how their electrical properties change over time.

The Principle of Resistive Heating

Like all resistive heaters, a SiC element generates heat when electrical current passes through it. The amount of power (and thus heat) is determined by the voltage applied and the element's electrical resistance.

The Critical Concept of "Aging"

Over time, as the element is exposed to high temperatures, its surface slowly oxidizes. This oxidation process causes a gradual and irreversible increase in the element's electrical resistance.

This phenomenon is known as aging. It is a natural and expected part of the SiC element's lifecycle. An older element will have a significantly higher resistance than a new one.

The Impact on Power Supply

To maintain a constant power output (and therefore a stable temperature), you must compensate for the rising resistance. Since Power = (Voltage)² / Resistance, as the resistance (R) increases, the applied voltage (V) must also be increased.

This mandates the use of a variable voltage power supply, such as a transformer with multiple taps or a Silicon Controlled Rectifier (SCR), to ensure consistent and controlled heating throughout the element's life.

Practical Trade-offs and Considerations

While SiC offers premium performance, it comes with specific requirements and considerations that are crucial for successful implementation.

Managing the Aging Process

An SiC heating system is not a "set-and-forget" component. You must have a control system capable of adjusting voltage to maintain the desired temperature as the element ages. Without this, the heat output will drop over time.

Higher Initial Cost

Silicon Carbide is an expensive material, and the specialized power control systems required add to the overall cost of the heating system. This initial investment must be weighed against the element's long service life and high-temperature capabilities.

Operational Best Practices

To maximize the element's lifespan, it is recommended to operate the furnace on the lowest possible voltage that still achieves the required temperature. Careful handling during installation and regular furnace maintenance are also critical for preventing premature failure.

Making the Right Choice for Your Application

Selecting SiC heating elements depends entirely on the specific demands of your process.

- If your primary focus is maximum operating temperature and structural integrity: SiC is a leading choice for applications running between 1300°C and 1600°C where element deformation is unacceptable.

- If your primary focus is long-term operational control: You must budget for and implement a variable voltage power supply to effectively manage the element's natural aging process.

- If your primary focus is process reliability in harsh environments: SiC's chemical inertness and resistance to thermal shock make it an exceptionally durable option for demanding industrial furnaces and kilns.

By understanding its unique properties, particularly the aging process, you can effectively leverage Silicon Carbide for precise and reliable heating in the most demanding environments.

Summary Table:

| Property/Capability | Key Feature | Benefit |

|---|---|---|

| Max Operating Temp | Up to 1600°C (2912°F) | Ideal for extreme heat processes |

| Thermal Shock Resistance | Low thermal expansion & high conductivity | Withstands rapid heating/cooling cycles |

| Structural Integrity | No melting (sublimates at ~2700°C) | Resists sagging and deformation |

| Chemical Resistance | Inert material, resists oxidation/corrosion | Long life in harsh environments |

| Electrical Behavior | Resistance increases over time ("aging") | Requires variable voltage control for consistent power |

Ready to harness the power of Silicon Carbide for your high-temperature application?

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs. Our SiC heating solutions deliver the durability and extreme temperature performance your process demands.

Contact our heating experts today to discuss your requirements and get a tailored solution!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C