At its core, silicon carbide (SiC) is an advanced ceramic material defined by its exceptional ability to perform under extreme thermal and mechanical stress. Its primary properties are very high thermal conductivity, excellent strength at high temperatures, low thermal expansion, and strong chemical resistance. These attributes make it a critical component for applications requiring rapid and reliable heating, such as the elements in industrial furnaces and specialized laboratory equipment.

The true value of SiC is not found in a single property, but in its unique combination of thermal, mechanical, and electrical characteristics. This synergy allows it to solve complex engineering challenges where most other materials would fail, particularly in rapidly achieving and maintaining extreme temperatures without degrading.

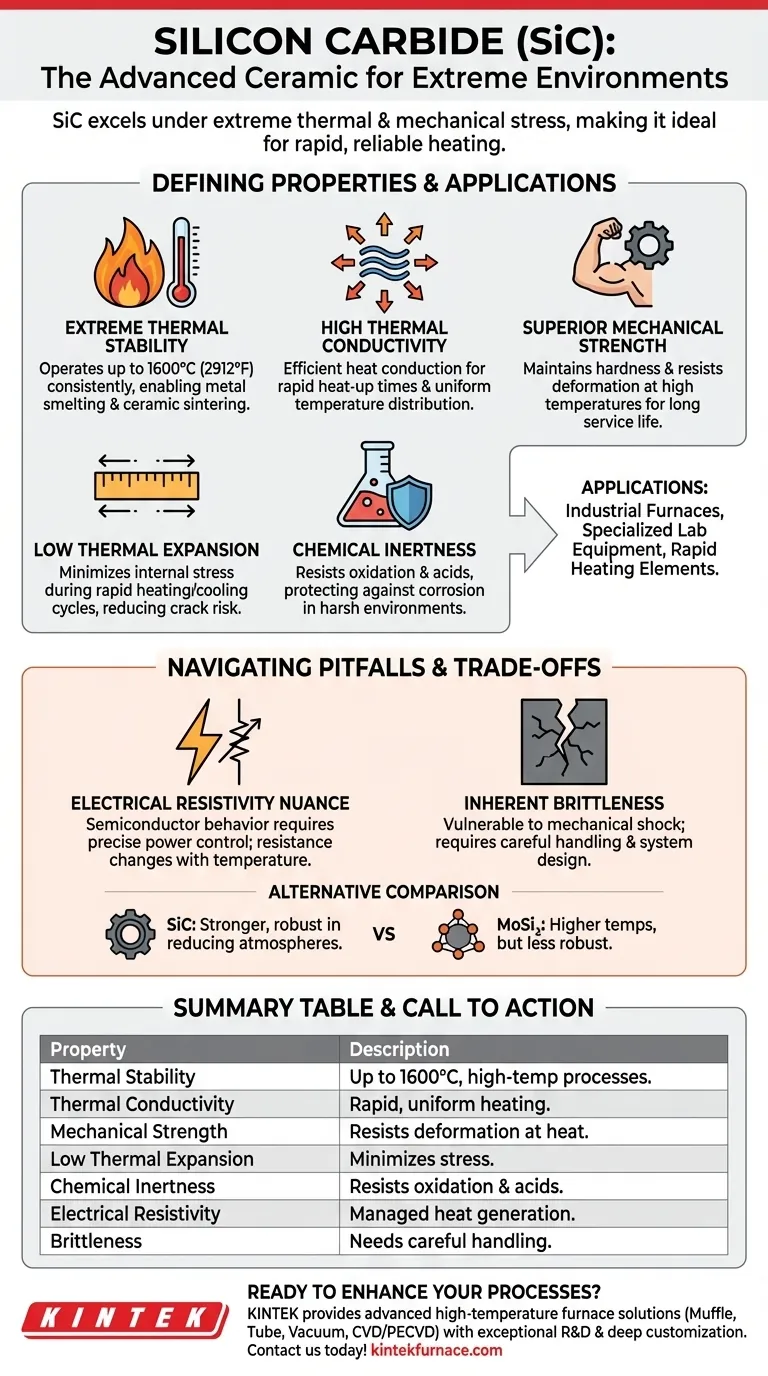

The Defining Properties of Silicon Carbide

To understand where SiC excels, we must first examine the core properties that set it apart. These characteristics work in concert to deliver its high-performance capabilities.

Extreme Thermal Stability

Silicon carbide heating elements can operate consistently at temperatures up to 1600°C (2912°F).

This allows for processes like metal smelting and ceramic sintering that are simply not possible with most other materials. Its stability ensures repeatable and reliable thermal performance cycle after cycle.

High Thermal Conductivity

Unlike ceramic insulators that block heat, SiC conducts it very efficiently.

This property is crucial for its role as a heating element. It enables rapid heat-up times and promotes a uniform temperature distribution within a furnace or chamber, leading to higher process efficiency and product quality.

Superior Mechanical Strength

SiC maintains its high strength and hardness even at extreme temperatures.

This mechanical robustness means it resists sagging, warping, or creeping under its own weight when hot. This directly contributes to a long and predictable service life in demanding industrial environments.

Low Thermal Expansion

When heated, SiC expands very little compared to metals and other ceramics.

This stability is critical. It prevents the buildup of internal mechanical stress during rapid heating and cooling cycles, drastically reducing the risk of cracks and structural failure.

Chemical Inertness

SiC exhibits strong resistance to both oxidation and acids, making it chemically stable in harsh environments.

This inertness protects the heating elements from corrosion and degradation, ensuring a longer lifespan when exposed to various process atmospheres, particularly in comparison to many metallic elements.

Common Pitfalls and Trade-offs

While powerful, SiC is not a universal solution. Understanding its limitations is essential for successful implementation and avoiding costly failures.

The Nuance of Electrical Resistivity

The term "electrical insulation" can be misleading. SiC is a semiconductor whose electrical resistance changes significantly with temperature.

At room temperature, its resistance is high, but as it heats up, its resistance profile allows it to efficiently convert electrical energy into heat. This property is fundamental to its function but must be managed by the power control system.

Inherent Brittleness

Like most advanced ceramics, SiC is very hard but also brittle. It has low tolerance for mechanical shock or impact.

Care must be taken during installation, handling, and operation to avoid fractures. System designs must account for vibration and isolate the SiC components from direct impact.

Comparison to Alternatives (MoSi₂)

In certain atmospheres, other materials may be considered. Molybdenum disilicide (MoSi₂) elements, for example, can often reach even higher temperatures than SiC.

However, SiC is generally stronger and more robust in reducing atmospheres. The choice between them depends on a careful analysis of the specific operating temperature, atmospheric chemistry, and mechanical demands of the application.

How to Apply This to Your Project

Selecting SiC depends entirely on the specific demands of your high-temperature application. Use these points as a guide for your decision-making.

- If your primary focus is rapid, uniform heating above 1200°C: SiC is an excellent choice due to its unmatched combination of thermal conductivity and high-temperature stability.

- If your primary focus is element longevity in a chemically aggressive environment: The chemical inertness of SiC gives it a distinct advantage over many metallic heating elements, ensuring durability.

- If your application involves significant mechanical shock or vibration: The inherent brittleness of SiC must be a central factor in your design, requiring careful mounting and handling protocols to prevent failure.

By understanding this balance of elite thermal performance and practical limitations, you can effectively leverage silicon carbide to achieve stability and efficiency in the most demanding thermal environments.

Summary Table:

| Property | Description |

|---|---|

| Thermal Stability | Operates up to 1600°C, ideal for high-temperature processes like sintering and smelting. |

| Thermal Conductivity | Enables rapid, uniform heating for efficient furnace performance. |

| Mechanical Strength | Maintains hardness and resists deformation under extreme heat for long service life. |

| Low Thermal Expansion | Minimizes stress and cracking during thermal cycling. |

| Chemical Inertness | Resists oxidation and acids, ensuring durability in harsh environments. |

| Electrical Resistivity | Semiconductor behavior allows efficient heat generation, managed by power systems. |

| Brittleness | Requires careful handling to avoid fractures from shock or vibration. |

Ready to enhance your high-temperature processes with reliable silicon carbide solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're in industrial heating or laboratory research, our SiC-based technologies ensure superior performance and efficiency. Contact us today to discuss how we can support your project with durable, high-performance heating elements and systems!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency