Nichrome 80/20 is the ideal alloy for industrial heating elements primarily due to its unique combination of high electrical resistivity and exceptional resistance to physical and chemical degradation at high temperatures. It allows furnaces to operate continuously at 800°C by efficiently converting electricity into heat while maintaining structural integrity against oxidation and creep.

Core Takeaway While many metals can generate heat, few can survive the process. Nichrome 80/20 is essential for industrial furnaces because it balances thermal efficiency with "high-temperature creep" resistance, preventing the element from deforming or failing under its own weight during sustained 800°C operations.

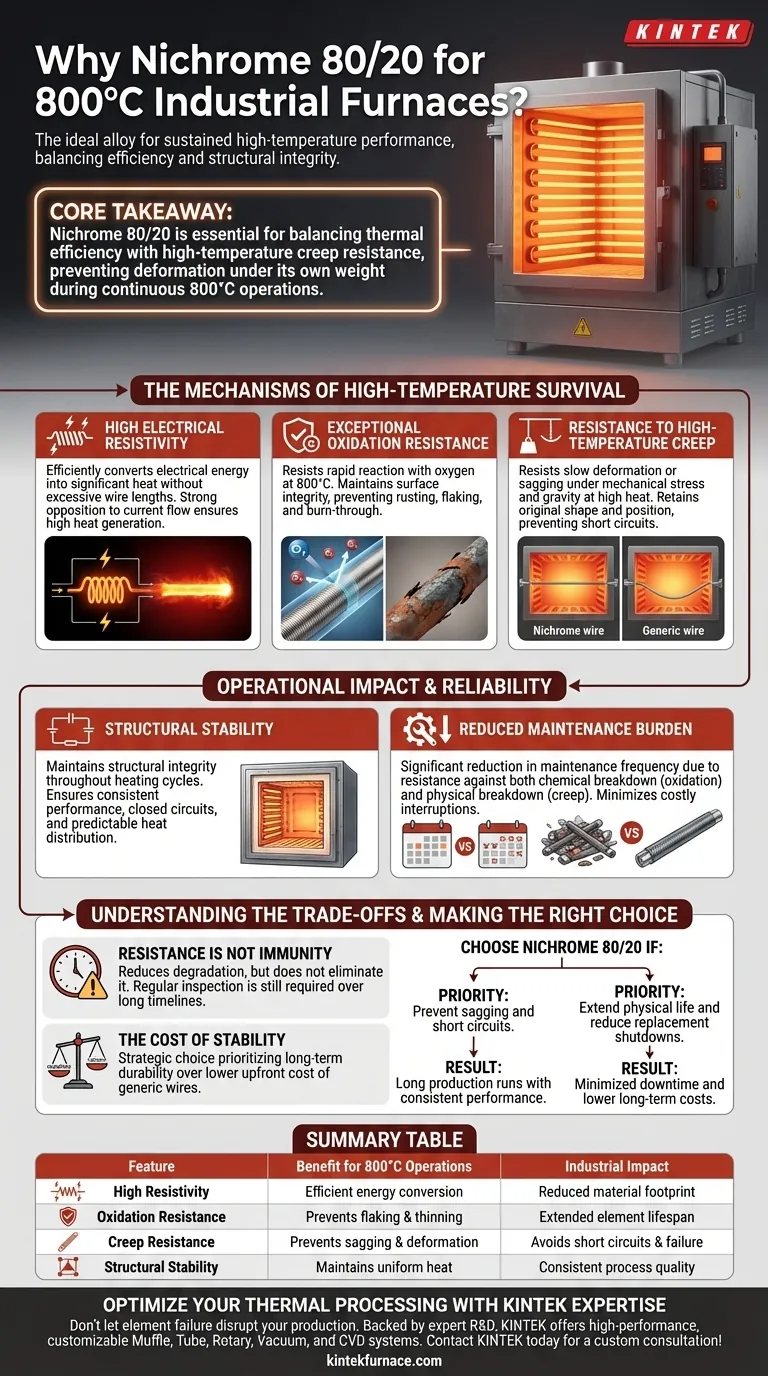

The Mechanisms of High-Temperature Survival

To understand why Nichrome 80/20 is specified for these environments, we must look at how it handles the three main stressors of industrial heating: electrical resistance, chemical attack, and mechanical stress.

High Electrical Resistivity

The primary function of a heating element is to convert electrical energy into thermal energy.

Nichrome 80/20 possesses high electrical resistivity. This property ensures that the material strongly opposes the flow of electricity, generating significant heat in the process without requiring excessive lengths of wire.

Exceptional Oxidation Resistance

At 800°C, most standard metals react rapidly with oxygen, causing them to rust, flake, and eventually burn through.

Nichrome 80/20 is specifically engineered to resist this oxidation. It maintains its surface integrity even when exposed to air at high temperatures, preventing the material degradation that leads to element failure.

Resistance to High-Temperature Creep

One of the most critical, yet overlooked, factors in furnace design is "creep"—the tendency of a solid material to slowly deform or sag under mechanical stress when heated.

At 800°C, gravity can cause inferior wires to stretch or sag, leading to short circuits or physical breakage. Nichrome 80/20 offers exceptional resistance to this phenomenon, ensuring the heating coil retains its original shape and position over time.

Operational Impact and Reliability

Beyond the material physics, using Nichrome 80/20 has direct implications for the operational efficiency of the furnace.

Structural Stability

Industrial furnaces often run continuously. Stability is not just about staying intact; it is about consistent performance.

This alloy maintains structural stability throughout the heating cycle. This ensures the electrical circuit remains closed and the heat distribution remains predictable.

Reduced Maintenance Burden

Material degradation is the primary cause of downtime in electric furnaces.

Because Nichrome 80/20 resists both chemical breakdown (oxidation) and physical breakdown (creep), it significantly reduces the frequency of maintenance. This durability minimizes the need for costly interruptions to replace worn-out elements.

Understanding the Trade-offs

While Nichrome 80/20 is highly effective, it is important to understand the limits of its "resistance" to ensure realistic expectations.

Resistance is Not Immunity

The primary reference notes that this alloy reduces the need for maintenance caused by degradation, but it does not eliminate it entirely.

Over long enough timelines, even Nichrome 80/20 will eventually succumb to the harsh environment of an 800°C furnace. Regular inspection is still required, though at much longer intervals than with lesser alloys.

The Cost of Stability

The engineering behind this alloy focuses on stability and longevity.

Using a specialized alloy like Nichrome 80/20 is a strategic choice to prioritize long-term durability over the lower upfront cost of generic conductive wires, which would fail rapidly in this temperature range.

Making the Right Choice for Your Goal

When selecting heating elements for an 800°C application, your priorities will dictate your material choice.

- If your primary focus is Operational Continuity: Choose Nichrome 80/20 for its ability to resist creep, ensuring the element does not sag and short out during long production runs.

- If your primary focus is Maintenance Reduction: Rely on this alloy to withstand oxidation, which extends the physical life of the wire and reduces the frequency of replacement shutdowns.

In summary, Nichrome 80/20 is the definitive choice for 800°C operations because it solves the dual problem of generating efficient heat while physically surviving the environment it creates.

Summary Table:

| Feature | Benefit for 800°C Operations | Industrial Impact |

|---|---|---|

| High Resistivity | Efficient electrical-to-thermal energy conversion | Reduced material footprint |

| Oxidation Resistance | Prevents surface flaking and material thinning | Extended element lifespan |

| Creep Resistance | Prevents sagging or deformation under heat | Avoids short circuits & failure |

| Structural Stability | Maintains uniform heat distribution | Consistent process quality |

Optimize Your Thermal Processing with KINTEK Expertise

Don't let element failure disrupt your production. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique high-temperature needs. Whether you require standard solutions or bespoke furnace designs, our team ensures your lab or industrial facility achieves maximum reliability and efficiency.

Ready to upgrade your high-temp equipment? Contact KINTEK today for a custom consultation!

Visual Guide

References

- Gustavo Ribeiro Zanini, LUIS CARLOS GERON. PROJETO DE UM FORNO ELÉTRICO INDUSTRIAL PARA TRATAMENTO TÉRMICO TUBOS DE AÇO SA-178 GR A. DOI: 10.52138/citec.v17i01.437

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

People Also Ask

- How do Type-S thermocouples contribute to monitoring temperature fields in niobium furnaces for precise heat treatment?

- What are the properties and uses of pure platinum as a heating element? Ideal for High-Temp Precision and Purity

- What are the characteristics of Molybdenum Disilicide (MoSi2) as a heating element? Unlock Extreme Heat for Your Lab

- What is the maximum operating temperature for Silicon Carbide heating elements? Unlock High-Temp Efficiency Up to 1600°C

- What is the design and primary advantage of SC Type Silicon Carbide Heating Elements? Achieve Uniform Heat for Large Furnaces

- What are the temperature capabilities of molybdenum disilicide heating elements? Reach up to 1850°C for high-temperature furnace needs

- What is the basic function of heating elements? Convert Electricity to Controlled Heat Efficiently

- How are MoSi2 heating elements used in metal heat treatment? Achieve Superior Heat Treatment for Metals