For high-temperature applications requiring extreme reliability, pure platinum serves as a premier heating element material. It is primarily chosen for its exceptional stability and resistance to oxidation in operating temperatures ranging from 1450°C to 1600°C, making it indispensable for specialized industrial and scientific equipment.

The decision to use a pure platinum heating element is rarely about heat alone. It is a strategic choice for applications where precise temperature control, process purity, and long-term performance in corrosive, high-heat environments justify its significant cost.

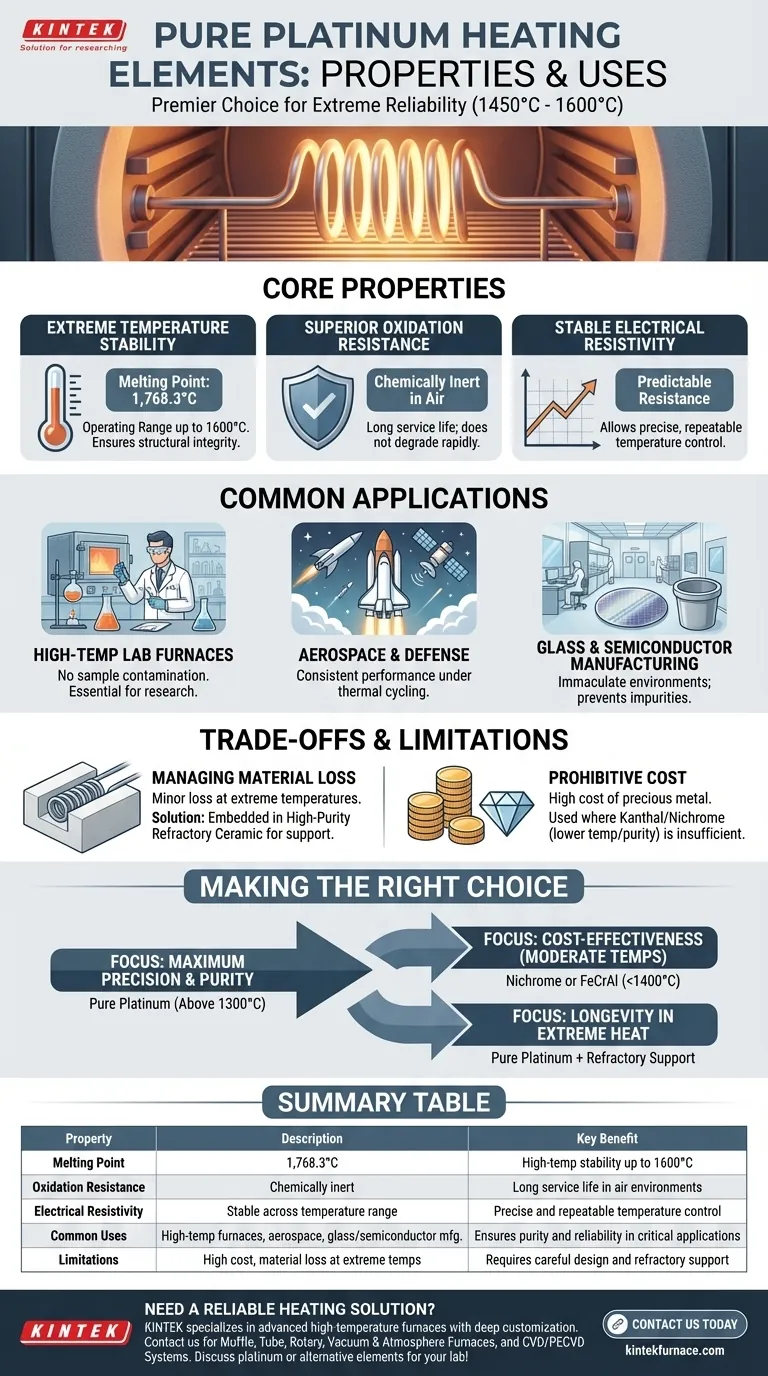

The Core Properties Defining Platinum's Performance

The value of platinum as a heating element is rooted in a unique combination of physical and chemical properties that set it apart from other materials.

Extreme Temperature Stability

Pure platinum has a very high melting point of 1,768.3°C. This provides a significant safety margin above its typical maximum operating temperature of 1600°C, ensuring structural integrity under intense thermal stress.

Superior Oxidation Resistance

Unlike many metals that rapidly degrade when heated in the presence of air, platinum is chemically inert and highly resistant to oxidation. This property is the primary reason for its long service life and reliability in high-temperature furnaces.

Stable Electrical Resistivity

Platinum exhibits a known and stable electrical resistance across a vast temperature range. This predictability is critical, as it allows for highly precise and repeatable temperature control, which is essential for scientific experiments and sensitive manufacturing processes.

Common Applications and Use Cases

Platinum's unique characteristics make it the material of choice for applications where failure is not an option and performance cannot be compromised.

High-Temperature Laboratory Furnaces

In research and material science, furnaces must provide consistent heat without introducing contaminants. Platinum's inertness ensures that the heating element itself does not react with or corrupt the samples being processed.

Aerospace and Defense Components

The absolute reliability of platinum makes it suitable for critical aerospace systems. Its ability to perform consistently under extreme thermal cycling is vital for components where maintenance is impossible and performance is paramount.

Glass and Semiconductor Manufacturing

Processes like manufacturing high-purity glass or growing semiconductor crystals require immaculate environments and precise thermal management. Platinum elements provide the necessary control and do not shed impurities that could ruin the final product.

Understanding the Trade-offs and Limitations

While platinum offers unmatched performance, its use comes with practical challenges that must be managed in any engineering design.

Managing Material Loss at High Temperatures

Even platinum is not entirely immune to degradation. At the upper end of its operating range, it can experience minor oxide and metal losses through vaporization.

To combat this, platinum elements are often embedded within a high-purity refractory ceramic. This supportive structure not only minimizes material loss but also provides essential mechanical support at temperatures where the metal softens.

The Prohibitive Cost Factor

The most significant barrier to the widespread use of platinum is its high cost as a precious metal. Its use is therefore reserved for applications where cheaper alternatives like Kanthal (FeCrAl) or Nichrome (NiCr) cannot meet the extreme temperature or purity requirements.

Making the Right Choice for Your Application

Selecting a heating element requires balancing performance requirements with budget and design constraints.

- If your primary focus is maximum precision and purity: Pure platinum is the definitive choice for operating temperatures above 1300°C, especially when process contamination must be eliminated.

- If your primary focus is cost-effectiveness for moderate temperatures: You should investigate nichrome or FeCrAl alloys, which offer excellent performance for applications below 1400°C at a fraction of the cost.

- If your primary focus is longevity in extreme heat: Your design must include embedding the platinum element in a compatible, high-purity refractory material to ensure a long and reliable service life.

Ultimately, choosing platinum is an investment in certainty for the most demanding thermal applications.

Summary Table:

| Property | Description | Key Benefit |

|---|---|---|

| Melting Point | 1,768.3°C | High-temperature stability up to 1600°C |

| Oxidation Resistance | Chemically inert | Long service life in air environments |

| Electrical Resistivity | Stable across temperature range | Precise and repeatable temperature control |

| Common Uses | High-temperature furnaces, aerospace, glass/semiconductor manufacturing | Ensures purity and reliability in critical applications |

| Limitations | High cost, material loss at extreme temperatures | Requires careful design and refractory support |

Need a reliable heating solution for your high-temperature applications? KINTEK specializes in advanced high-temperature furnaces with deep customization to meet your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by exceptional R&D and in-house manufacturing. Whether you're in research, aerospace, or manufacturing, we can help you achieve precise temperature control and process purity. Contact us today to discuss how our platinum-based or alternative heating elements can enhance your lab's performance and efficiency!

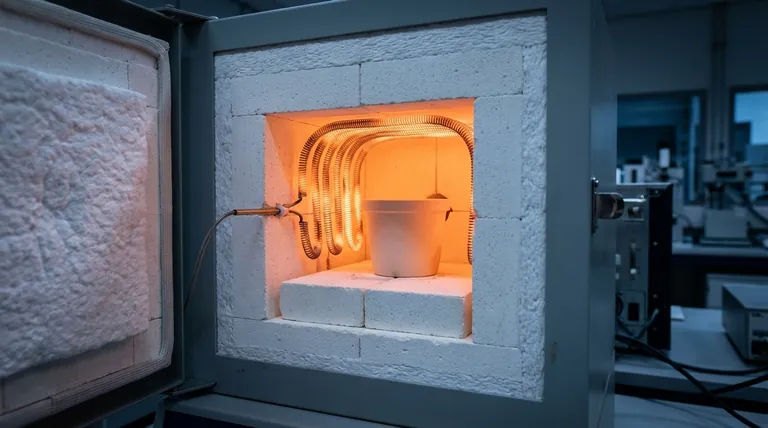

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How can high temperature heating elements be customized for different applications? Tailor Elements for Peak Performance

- What is the temperature range where MoSi2 heating elements should not be used for long periods? Avoid 400-700°C to Prevent Failure

- What are the advantages of using molybdenum-disilicide heating elements for aluminum alloy processing? (Rapid Heating Guide)

- What types of molybdenum disilicide heating elements are available? Choose the Right Element for Your High-Temp Needs

- What are the primary applications of MoSi2 heating elements in research? Achieve Reliable High-Temp Control for Material Synthesis