Molybdenum Disilicide (MoSi2) is a specialized ceramic-metallic composite prized for its ability to function as a heating element at extremely high temperatures in oxidizing atmospheres. Its defining characteristics are a very high melting point and exceptional resistance to oxidation, allowing it to generate furnace temperatures between 1600°C and 1700°C. However, this high-temperature performance is coupled with significant brittleness at room temperature.

The core value of MoSi2 lies in its superior longevity and stability at extreme heat, making it the material of choice for furnaces operating above 1500°C. This advantage is balanced by a critical vulnerability: the material is extremely fragile below its transition temperature of approximately 1000°C, demanding careful handling.

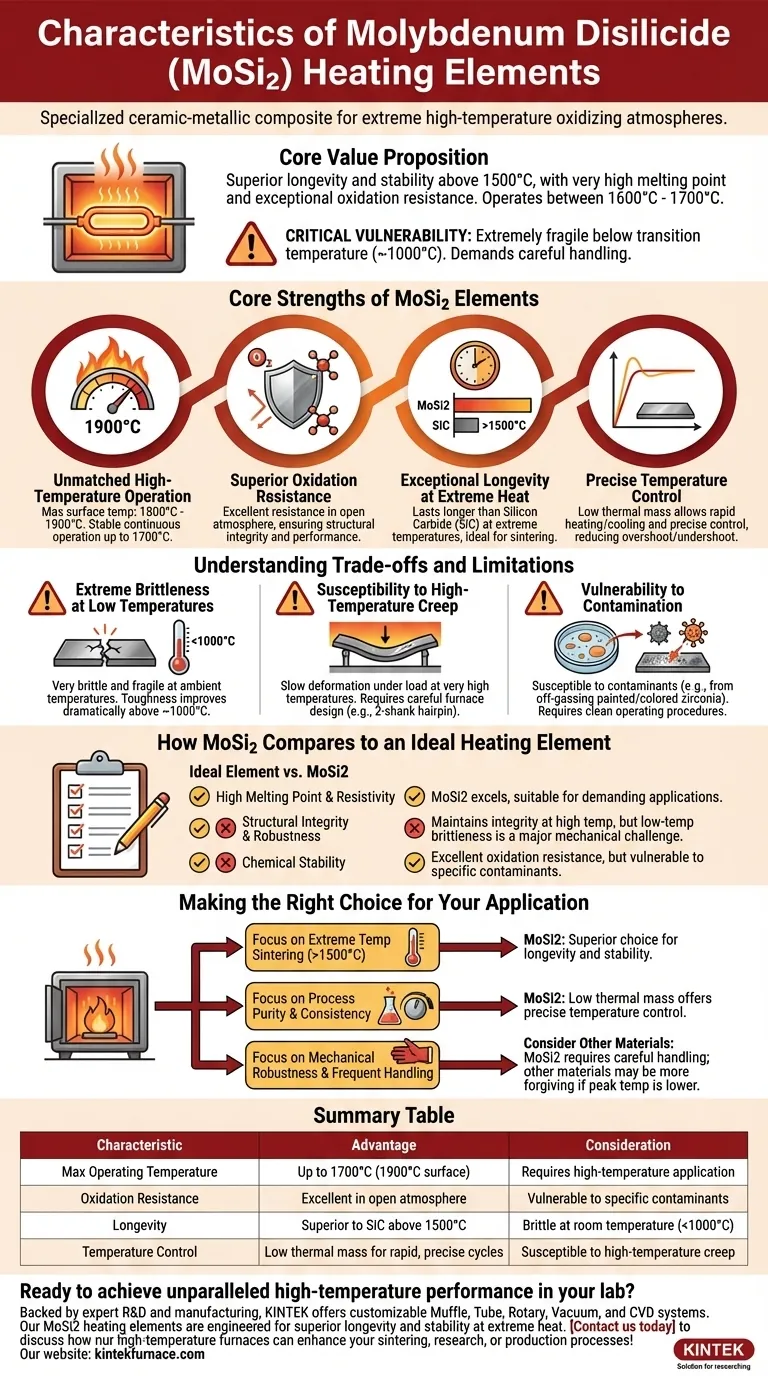

The Core Strengths of MoSi2 Elements

Molybdenum Disilicide is not a general-purpose heating material; it is a high-performance solution chosen for its unique advantages in demanding thermal environments.

Unmatched High-Temperature Operation

MoSi2 elements can achieve a maximum surface temperature between 1800°C and 1900°C. This allows furnaces using these elements to be programmed for stable, continuous operation at temperatures up to 1700°C.

Superior Oxidation Resistance

The material is a cermet (a ceramic-metallic composite) that exhibits excellent resistance to oxidation, even in an open atmosphere. This chemical stability is crucial for maintaining structural integrity and performance over long operational lifetimes at extreme heat.

Exceptional Longevity at Extreme Heat

When operated at temperatures above 1500°C, MoSi2 elements can last significantly longer than alternatives like Silicon Carbide (SiC). This makes them a more reliable choice for applications such as high-temperature sintering.

Precise Temperature Control

MoSi2 elements have a low thermal mass. This property allows for rapid heating and cooling cycles with precise temperature control, reducing the overshooting and undershooting of set temperatures.

Understanding the Trade-offs and Limitations

To leverage the benefits of MoSi2, one must understand and mitigate its inherent weaknesses. These are not flaws but fundamental properties of the material.

Extreme Brittleness at Low Temperatures

The most significant drawback of MoSi2 is its low toughness at ambient temperatures. The elements are very brittle and must be handled with extreme care during installation, maintenance, and any time the furnace is cold.

Its toughness improves dramatically only after it passes its brittle-ductile transition temperature, which is around 1000°C.

Susceptibility to High-Temperature Creep

Under mechanical load at very high temperatures, MoSi2 can be susceptible to creep. This is a slow deformation over time that can alter the element's shape and must be considered in the furnace design. A common design to manage this is the 2-shank hairpin shape.

Vulnerability to Contamination

MoSi2 elements are more susceptible to contamination issues than some other materials. For example, if painted or colored zirconia is sintered without being properly dried first, the off-gassing can damage the elements. Proper maintenance and clean operating procedures are critical.

How MoSi2 Compares to an Ideal Heating Element

An ideal heating element possesses a combination of thermal, mechanical, and electrical properties. MoSi2 excels in some areas while compromising in others.

High Melting Point and Resistivity

An ideal element needs a high melting point and high specific resistance to generate heat efficiently and safely. MoSi2 meets these requirements exceptionally well, making it suitable for the most demanding applications.

Structural Integrity and Robustness

Heating elements must withstand repeated thermal cycling. While MoSi2 maintains its integrity at high temperatures, its low-temperature brittleness presents a significant mechanical challenge compared to more ductile materials.

Chemical Stability

Freedom from oxidation and corrosion is paramount. MoSi2's resistance to oxidation is a primary feature, though its specific vulnerability to certain contaminants must be managed.

Making the Right Choice for Your Application

Selecting MoSi2 is a decision based on balancing performance needs with operational realities.

- If your primary focus is extreme temperature sintering (>1500°C): MoSi2 is the superior choice for its longevity and stable performance in oxidizing atmospheres at these temperatures.

- If your primary focus is process purity and consistency: The precise temperature control offered by MoSi2's low thermal mass is a significant advantage.

- If your primary focus is mechanical robustness and frequent handling: The inherent brittleness of MoSi2 requires careful, established procedures; other materials may be more forgiving if peak operating temperatures are lower.

Ultimately, choosing MoSi2 is a commitment to achieving unparalleled high-temperature performance, provided you can accommodate its specific handling and operational requirements.

Summary Table:

| Characteristic | Advantage | Consideration |

|---|---|---|

| Max Operating Temperature | Up to 1700°C (1900°C surface) | Requires high-temperature application |

| Oxidation Resistance | Excellent in open atmosphere | Vulnerable to specific contaminants |

| Longevity | Superior to SiC above 1500°C | Brittle at room temperature (<1000°C) |

| Temperature Control | Low thermal mass for rapid, precise cycles | Susceptible to high-temperature creep |

Ready to achieve unparalleled high-temperature performance in your lab?

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique needs. Our MoSi2 heating elements are engineered for superior longevity and stability at extreme heat.

Contact us today to discuss how our high-temperature furnaces can enhance your sintering, research, or production processes!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality