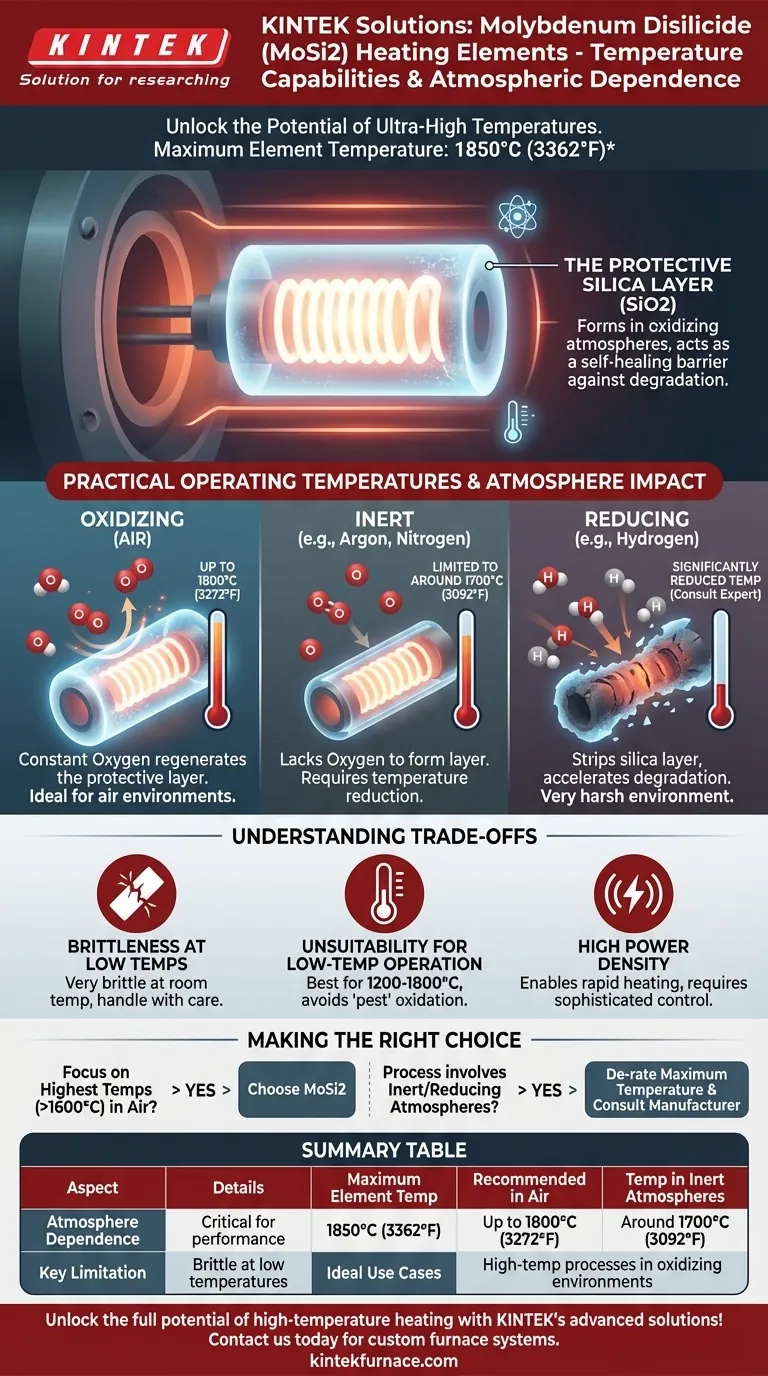

At their peak, molybdenum disilicide (MoSi2) heating elements are capable of reaching element temperatures as high as 1850°C (3362°F). This makes them one of the highest-temperature metallic-based heating elements available for industrial and laboratory furnaces. However, this maximum temperature is only achievable under specific, ideal conditions.

The exceptional temperature capability of MoSi2 heating elements is entirely dependent on the furnace atmosphere. They thrive in oxidizing environments that form a protective surface layer but see their performance significantly reduced in inert or reducing atmospheres.

Understanding the Core Mechanism: The Protective Silica Layer

Molybdenum disilicide's unique properties are not inherent to the base material alone but are a result of how it interacts with its environment at high temperatures.

### How It Forms

When a MoSi2 element is heated in an oxidizing atmosphere like air, its surface reacts with oxygen. This reaction forms a thin, non-porous passivation layer of pure silica (SiO2), which is essentially a type of glass.

### Why It's Critical for Performance

This silica layer is the key to the element's success. It acts as a protective barrier, preventing the underlying MoSi2 material from further oxidation and degradation. This self-healing "skin" allows the element to operate reliably for long periods at extreme temperatures.

Practical Operating Temperatures and Limits

The stated 1850°C maximum is a material limit. The practical, recommended operating temperature is dictated by the chemical environment inside the furnace.

### In Standard Oxidizing Atmospheres (Air)

In a standard air atmosphere, MoSi2 elements can be operated continuously at furnace temperatures up to 1800°C (3272°F). The presence of oxygen constantly regenerates the protective silica layer if it is damaged.

### In Inert Atmospheres (e.g., Argon, Nitrogen)

Operating in an inert gas atmosphere removes the oxygen needed to form and maintain the protective silica layer. This requires a temperature reduction of at least 100°C, limiting the maximum practical temperature to around 1700°C (3092°F).

### In Reducing Atmospheres (e.g., Hydrogen)

Reducing atmospheres are particularly harsh on MoSi2 elements. Atmospheres containing hydrogen will actively strip the protective silica layer, leading to accelerated degradation of the element. This requires a significant reduction in operating temperature. Using moist hydrogen can help reform a protective layer and improve performance, but specialized guidance is essential.

Understanding the Trade-offs

While MoSi2 offers unparalleled temperature performance, it comes with specific material properties and limitations that must be managed.

### Brittleness at Low Temperatures

MoSi2 is a cermet (ceramic-metallic composite) and is extremely brittle and fragile at room temperature. It must be handled with great care during shipping, installation, and furnace maintenance to avoid fracture. It only gains ductility as it heats up.

### Unsuitability for Low-Temperature Operation

These elements are designed for very high temperatures, typically operating in a range from 1200°C to 1800°C. They are not well-suited for prolonged operation at lower temperatures, where they can be susceptible to a form of accelerated oxidation known as "pest."

### High Power Density

MoSi2 elements can handle very high watt loadings. This means they can radiate a large amount of power from a small surface area, enabling rapid furnace heating. This high power must be managed with sophisticated control systems to avoid thermal shock to the furnace or product.

Making the Right Choice for Your Process

Your furnace's internal atmosphere is the most critical factor when designing around MoSi2 elements.

- If your primary focus is reaching the absolute highest temperatures (above 1600°C) in an air atmosphere: MoSi2 is the definitive choice due to its superior temperature rating and long service life.

- If your process involves an inert or reducing atmosphere: You must de-rate the maximum temperature of MoSi2 elements and consult manufacturer specifications for your specific gas mixture.

- If your concern is mechanical robustness during handling: Implement strict protocols for handling MoSi2 elements at room temperature, as they are very brittle before being heated.

Understanding these environmental dependencies is the key to successfully leveraging the exceptional capabilities of MoSi2.

Summary Table:

| Aspect | Details |

|---|---|

| Maximum Element Temperature | 1850°C (3362°F) under ideal conditions |

| Recommended Operating Temperature in Air | Up to 1800°C (3272°F) |

| Temperature in Inert Atmospheres | Limited to around 1700°C (3092°F) |

| Key Limitation | Performance depends on furnace atmosphere; brittle at low temperatures |

| Ideal Use Cases | High-temperature processes in oxidizing environments, rapid heating applications |

Unlock the full potential of high-temperature heating with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable MoSi2 heating elements and custom furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs, enhancing efficiency and performance. Contact us today to discuss how we can support your high-temperature applications and deliver tailored solutions for your lab!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing