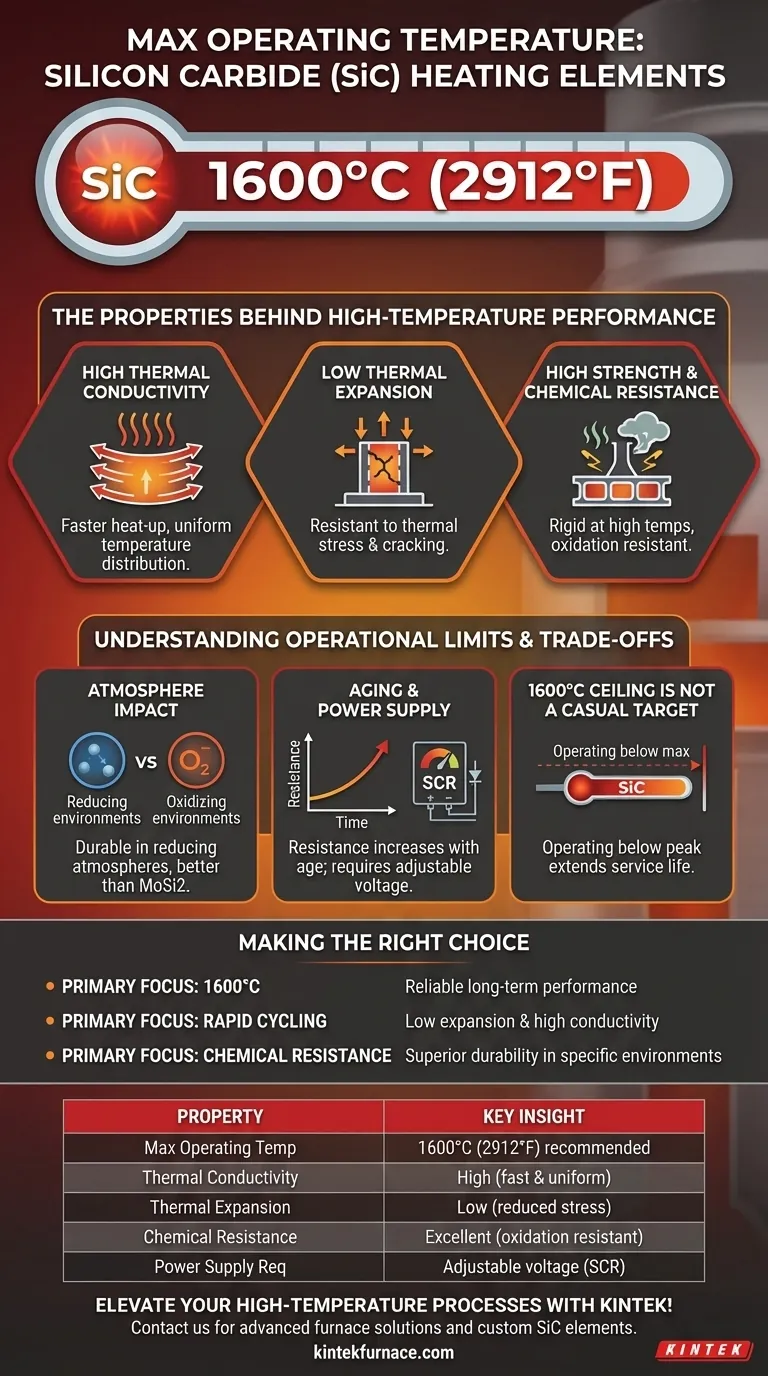

In short, the maximum recommended operating temperature for Silicon Carbide (SiC) heating elements is 1600°C (2912°F). While they can briefly exceed this, consistent operation at this upper limit is what defines their high-temperature capability in industrial and laboratory furnaces.

While the 1600°C temperature ceiling is the headline feature, the true value of Silicon Carbide lies in the combination of properties that make it a durable and efficient choice for demanding, high-heat applications. Understanding these characteristics is key to achieving optimal performance and lifespan.

The Properties Behind High-Temperature Performance

The ability of SiC to reliably operate at such high temperatures is not due to a single trait, but a combination of inherent physical and chemical properties. These factors work together to ensure efficiency, longevity, and stability.

Exceptional Thermal Conductivity

Silicon Carbide exhibits very high thermal conductivity. This means it transfers heat energy very efficiently.

For your application, this translates directly to faster furnace heat-up times and more uniform temperature distribution within the heating chamber, preventing hot or cold spots.

Low Thermal Expansion

A key challenge for any material cycled to extreme temperatures is thermal stress. SiC has a low coefficient of thermal expansion.

This property makes it highly resistant to the physical stress of rapid heating and cooling cycles, significantly reducing the risk of cracking or mechanical failure and extending its operational life.

Inherent Strength and Chemical Resistance

Even at 1600°C, SiC maintains high mechanical strength. Unlike many materials that soften or deform, it remains rigid and stable.

Furthermore, it is highly resistant to oxidation and chemical attack. This ensures the element does not degrade quickly when exposed to air or process atmospheres at high temperatures, contributing to its long service life.

Understanding the Operational Limits and Trade-offs

Simply knowing the maximum temperature is not enough for proper system design. To deploy SiC elements effectively, you must understand their operational behavior and limitations.

The Impact of Atmosphere

While robust, the performance and lifespan of a SiC element can be influenced by the furnace atmosphere. They are particularly strong and durable in reducing atmospheres.

This makes them a superior choice to alternatives like Molybdenum Disilicide (MoSi2) elements in specific chemical environments, although the best choice always depends on the precise process gases involved.

The Aging Factor and Power Supply Needs

Silicon Carbide elements age over their service life, causing their electrical resistance to gradually increase. This is a critical operational characteristic to manage.

Because of this aging process, a simple fixed-voltage power source is inadequate. A properly designed power supply, such as one using a multi-tap transformer or a Silicon Controlled Rectifier (SCR), is necessary to increase the voltage over time and maintain constant power output to hold the target temperature.

The 1600°C Limit is Not a Casual Target

Operating any component at its absolute maximum rated limit will shorten its lifespan. While SiC can run at 1600°C, most industrial applications are designed to operate slightly below this peak.

Running at a temperature of 1500°C to 1550°C, for instance, can significantly extend the element's service life compared to continuous operation at its absolute limit.

Making the Right Choice for Your Application

Selecting a heating element requires balancing performance, longevity, and operational cost. Your specific goal determines how you should leverage SiC's capabilities.

- If your primary focus is reaching temperatures up to 1600°C: Silicon Carbide is one of the premier choices for reliable, long-term performance in this range.

- If your primary focus is rapid heating cycles and thermal stability: SiC's low thermal expansion and high conductivity make it an excellent choice for applications requiring frequent cycling without element damage.

- If your primary focus is longevity in a specific chemical environment: Evaluate SiC's known resistance profile against your process atmosphere, as it often provides superior durability compared to other high-temperature elements.

Understanding these underlying material properties empowers you to design a more efficient, reliable, and long-lasting high-temperature system.

Summary Table:

| Property | Key Insight |

|---|---|

| Max Operating Temperature | 1600°C (2912°F) recommended for reliable performance |

| Thermal Conductivity | High, enabling fast heat-up and uniform temperature distribution |

| Thermal Expansion | Low, reducing stress from heating/cooling cycles and extending life |

| Chemical Resistance | Excellent, resisting oxidation and degradation in various atmospheres |

| Power Supply Requirement | Needs adjustable voltage (e.g., SCR) to compensate for resistance aging |

Elevate your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable Silicon Carbide heating elements and custom high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs, enhancing efficiency and durability. Contact us today to discuss how we can optimize your setup for superior performance and longevity!

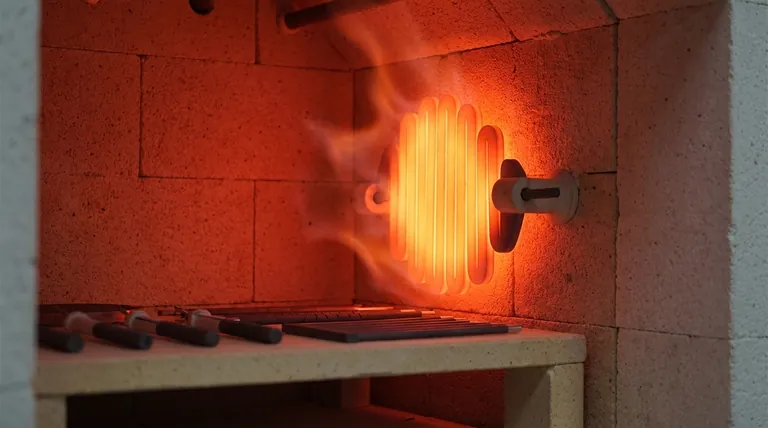

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability