Among its many strengths, a key property of silicon carbide (SiC) is its rare combination of high-temperature resistance and excellent thermal conductivity. Unlike most ceramics which act as thermal insulators, SiC can withstand extreme heat (up to 1450°C) while also transferring that heat very efficiently, a characteristic more commonly found in metals.

Silicon carbide's defining feature is not a single property, but its unique duality. It possesses the core strengths of a ceramic—hardness, high-temperature stability, and chemical resistance—while also exhibiting metal-like thermal and electrical conductivity.

The Unique Duality of Silicon Carbide

Most materials force a choice between thermal conductivity and high-temperature stability. Metals conduct heat well but melt at relatively low temperatures, while most ceramics withstand immense heat but insulate against it. Silicon carbide breaks this rule.

Resisting Extreme Temperatures

Silicon carbide maintains its structural integrity and chemical stability at very high temperatures, with some grades performing reliably in environments up to 1450°C (2640°F).

This makes it an ideal material for applications like industrial furnace components, kiln furniture, and high-temperature sensors where other materials would degrade or fail.

Excellent Thermal Conductivity

A key differentiator for SiC is its ability to conduct heat quickly and efficiently. Where a material like alumina or zirconia would block heat transfer, SiC allows it to pass through.

This property is critical for applications that require rapid heating, cooling, or uniform temperature distribution, such as in heat exchangers or semiconductor processing equipment.

The Electrical Conductivity Anomaly

While most ceramics are excellent electrical insulators, silicon carbide is a semiconductor. Its electrical conductivity is relatively high for a ceramic material.

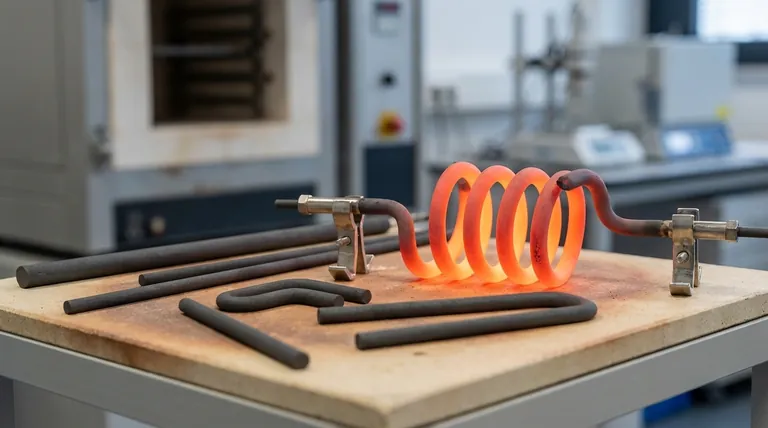

This specific property allows it to be used as an electrical heating element. By passing an electric current through it, the material heats up due to its resistance—a process known as Joule heating.

Unmatched Hardness and Durability

Beyond its thermal properties, SiC is an extremely hard and wear-resistant material. It also exhibits strong resistance to oxidation and chemical attack, even at elevated temperatures.

This combination of hardness and chemical stability results in an exceptionally long service life for components, reducing maintenance and replacement costs over time.

Understanding the Trade-offs

No material is perfect. While silicon carbide's properties are remarkable, it's important to understand its limitations to use it effectively.

Brittleness Under Impact

Like most advanced ceramics, silicon carbide is hard but brittle. It has low fracture toughness compared to metals, meaning it can crack or shatter under sudden mechanical shock or high tensile stress.

Designs using SiC must account for this, often employing compressive loading and avoiding sharp impacts or stress concentrations.

Cost and Manufacturing

Producing high-purity, dense silicon carbide components is an energy-intensive and complex process. This makes the raw material and the final parts more expensive than those made from conventional metals or lower-grade ceramics.

The cost is justified by performance and longevity in applications where lesser materials would quickly fail.

Making the Right Choice for Your Application

Selecting a material requires aligning its properties with your primary engineering goal. Silicon carbide is a problem-solver for specific, demanding challenges.

- If your primary focus is efficient electric heating: SiC's combination of electrical conductivity, high-temperature stability, and thermal conductivity makes it a superior choice for high-performance heating elements.

- If your primary focus is high-temperature structural support: SiC is an excellent material for furnace parts and kiln furniture, provided the components are not subject to high mechanical impact.

- If your primary focus is wear and corrosion resistance: The inherent hardness and chemical stability of SiC make it ideal for seals, bearings, and nozzles in abrasive or corrosive environments.

Ultimately, understanding SiC's unique blend of metallic and ceramic traits is the key to unlocking its potential in the most demanding applications.

Summary Table:

| Property | Description |

|---|---|

| High-Temperature Resistance | Withstands up to 1450°C, maintaining structural integrity in extreme heat. |

| Excellent Thermal Conductivity | Efficiently transfers heat, unlike most insulating ceramics. |

| Electrical Conductivity | Acts as a semiconductor, suitable for electric heating elements. |

| Hardness and Durability | Extremely hard, wear-resistant, and chemically stable for long service life. |

| Brittleness | Low fracture toughness; prone to cracking under mechanical shock. |

| Cost | Higher due to complex, energy-intensive manufacturing processes. |

Unlock the full potential of silicon carbide in your high-temperature applications with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, enhancing efficiency and durability. Contact us today to discuss how our tailored solutions can elevate your lab's performance and reduce long-term costs!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer