At its core, designing a heating element is a balancing act. The process involves carefully selecting a material and shaping it to a specific length and thickness to achieve a target resistance. This resistance, when subjected to a known voltage, will generate a precise amount of heat according to fundamental electrical principles like Joule's Law (P = V²/R).

The central challenge of heating element design is not merely generating heat, but ensuring the element can consistently and safely dissipate that heat to maintain a stable operating temperature without destroying itself.

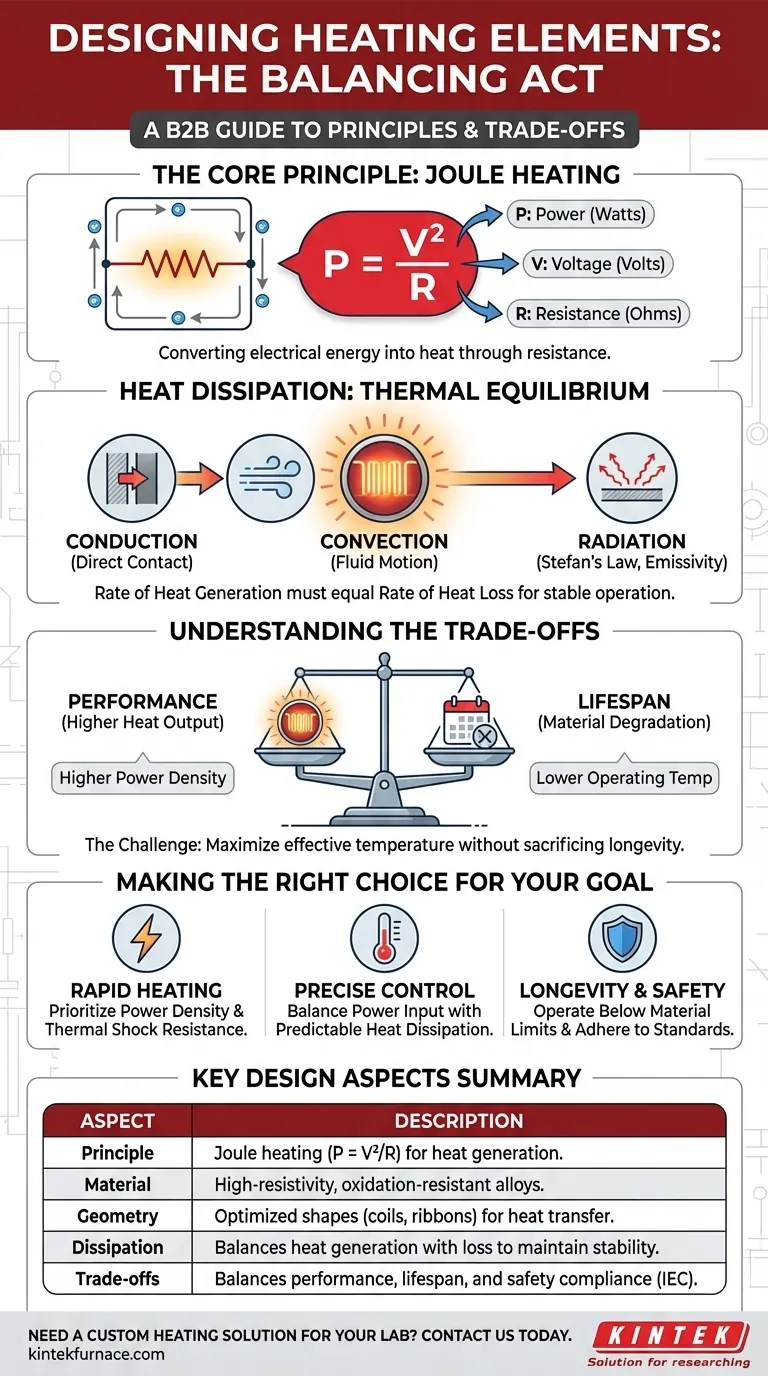

The Foundational Principle: Joule Heating

Every heating element operates on a simple principle known as Joule heating. This physical law describes how energy is converted into heat when an electric current encounters resistance.

Electrical Input as Power

The design process begins with the desired power output (in watts). Using the operating voltage (V), the target resistance (R) of the element is calculated using a variation of Ohm's Law: P = V²/R. This equation dictates the fundamental electrical characteristic of the element.

The Role of Material Resistance

The element itself is made from a material with high electrical resistivity. This property ensures that significant heat is generated even with a manageable length of wire. Common alloys are chosen for their ability to resist oxidation and maintain their strength at high temperatures. The material's specific resistance is a critical input for calculating the final dimensions of the element.

The Other Side of the Equation: Heat Dissipation

Generating heat is only half the battle. For an element to operate at a stable temperature, the rate of heat generation must equal the rate of heat loss to its surroundings. This is the thermal side of the design equation.

Heat Transfer and Thermal Equilibrium

An element loses heat through three mechanisms: conduction, convection, and radiation. The design must account for how the element will be used. For instance, an element designed for heating air relies on convection, while a toaster element relies primarily on radiation.

The Impact of Geometry

The physical shape of the element is not arbitrary; it is engineered for efficient heat transfer. Coiling a wire, for example, allows a very long resistor to fit into a small space, maximizing the surface area for convective heat transfer in devices like hair dryers. A flat ribbon, however, provides a broad surface ideal for radiant heating in toasters and ovens.

The Physics of Radiant Heat

For elements that glow, like those in an electric stove, Stefan's Law becomes a critical design formula. It helps calculate the amount of energy radiated from the element's surface based on its temperature and a material property called emissivity. This allows engineers to predict the final operating temperature.

Understanding the Trade-offs

An effective design is not just about hitting a target temperature; it's about balancing competing priorities and acknowledging real-world constraints.

Performance vs. Lifespan

Operating an element at a higher temperature results in greater heat output, but it also dramatically accelerates material degradation and reduces its operational lifespan. A core design trade-off involves finding the highest effective temperature that still allows for acceptable longevity.

Manufacturing and Tolerances

No manufacturing process is perfect. Regulatory bodies like the IEC (International Electrotechnical Commission) provide standards that specify allowable tolerances on an element's power rating. The design must account for these variations in material resistivity and final dimensions.

Safety and Compliance

Beyond performance, elements must be designed for safety. IEC standards also dictate critical safety parameters, including minimum insulation strength to prevent electrical shocks and limits on leakage current. These are non-negotiable constraints that protect the end-user.

Making the Right Choice for Your Goal

The final design of a heating element is dictated entirely by its intended application. When approaching a design, consider your primary objective.

- If your primary focus is rapid heating: The design must prioritize high power density (watts per unit area) and use materials that can withstand rapid temperature changes.

- If your primary focus is precise temperature control: The design must carefully balance electrical power input with predictable heat dissipation for the specific environment.

- If your primary focus is longevity and safety: The element must be designed to operate well below its material's maximum temperature limits and strictly adhere to all relevant safety standards.

Ultimately, designing a heating element is a direct application of physics to solve a practical engineering problem.

Summary Table:

| Key Aspect | Description |

|---|---|

| Principle | Based on Joule heating (P = V²/R) for heat generation from electrical resistance. |

| Material Selection | High-resistivity alloys chosen for durability, oxidation resistance, and temperature stability. |

| Geometry | Shapes like coils or ribbons optimized for heat transfer via conduction, convection, or radiation. |

| Heat Dissipation | Balances heat generation with loss to maintain stable temperature using principles like Stefan's Law. |

| Trade-offs | Considers performance vs. lifespan, manufacturing tolerances, and safety compliance (e.g., IEC standards). |

Need a custom heating solution for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to enhance your lab's efficiency and safety with tailored heating elements!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals