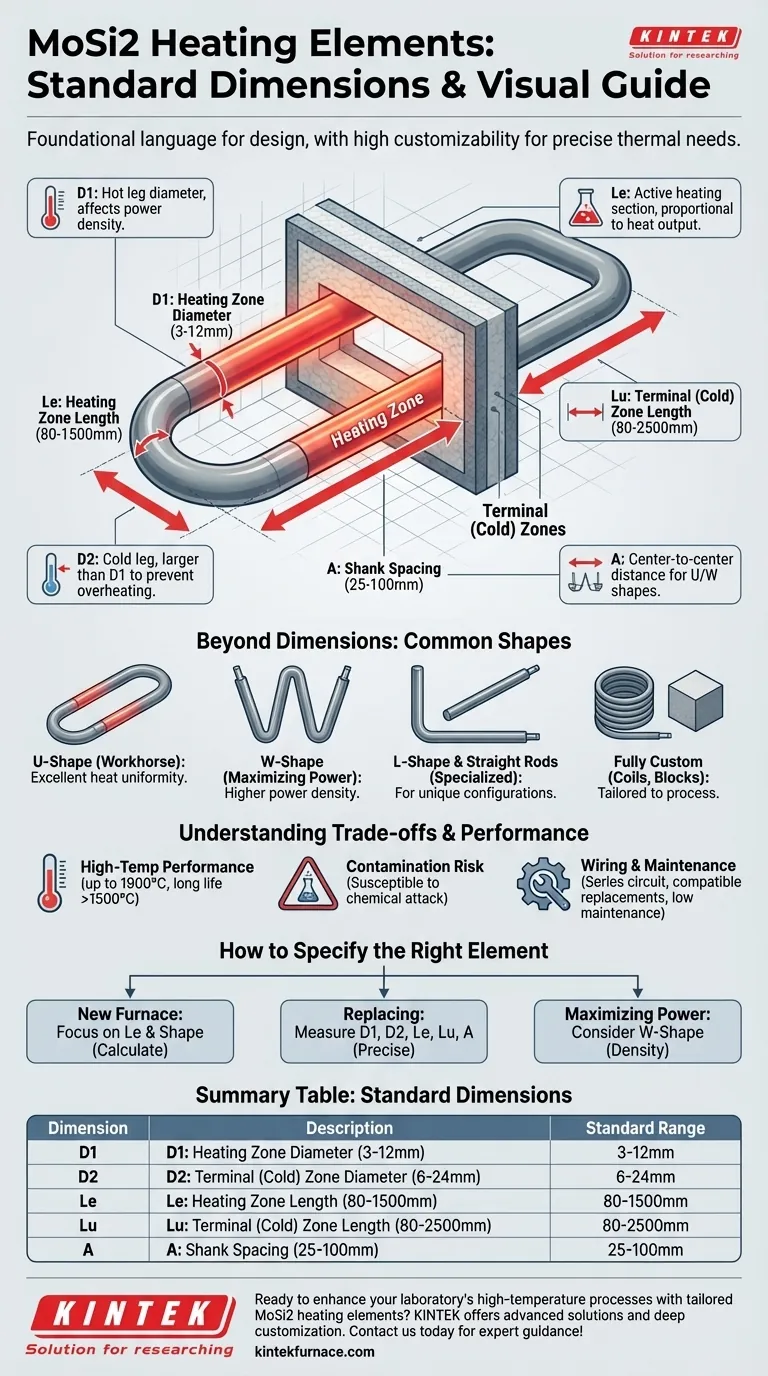

When specifying MoSi2 heating elements, the standard dimensions provide a foundational language for design. These common sizes include heating zone diameters (D1) from 3mm to 12mm, terminal or "cold" zone diameters (D2) from 6mm to 24mm, heating zone lengths (Le) from 80mm to 1500mm, terminal lengths (Lu) from 80mm to 2500mm, and shank spacing (A) from 25mm to 100mm.

While standard dimensions exist, they are best understood as a starting point. The true value of Molybdenum Disilicide (MoSi2) elements is their high degree of customizability, allowing them to be precisely tailored to the thermal and geometric needs of your furnace.

Deconstructing the Dimensions: A Visual Guide

Understanding what each dimension represents is critical for both designing new furnaces and replacing existing elements. These parameters define the element's performance and physical fit.

D1: The Heating Zone Diameter

This is the diameter of the "hot leg" of the element, the portion that resides inside the furnace chamber and radiates heat. It is the primary factor in determining the element's power density and resistance.

D2: The Terminal (Cold) Zone Diameter

This is the diameter of the "cold leg," which passes through the furnace insulation and connects to the power supply. The terminal diameter (D2) is always larger than the heating zone diameter (D1) to ensure lower electrical resistance, preventing the terminals from overheating where they pass through the refractory wall.

Le: The Heating Zone Length

This dimension specifies the length of the active heating section. The total heat output of an element is directly proportional to the surface area of this zone.

Lu: The Terminal (Cold) Zone Length

The terminal length must be sufficient to span the full thickness of the furnace's insulation and provide adequate space for electrical connections outside the furnace body.

A: The Shank Spacing

For U-shaped and W-shaped elements, this is the center-to-center distance between the legs (shanks). This dimension is critical for matching the element to the pre-drilled holes in the furnace roof or walls.

Beyond Dimensions: The Role of Shape

The shape of an element is determined by the furnace's design and the desired heat distribution. Standard dimensions apply across various common shapes.

The Workhorse: U-Shape Elements

The U-shape is the most common configuration. These elements are typically hung vertically from the furnace roof or mounted horizontally along the walls, providing excellent heat uniformity.

Maximizing Power: W-Shape Elements

A W-shape element is essentially two U-shapes joined together. It provides a higher concentration of heating power in a smaller area, making it ideal for compact furnaces or applications requiring very fast heat-up rates.

Specialized Geometries: L-Shape and Straight Rods

L-shaped elements are bent for use in specific designs where a standard U-shape may not fit, such as around corners. Straight rods are also available for unique furnace configurations.

Fully Custom Solutions

Beyond these common forms, MoSi2 elements can be manufactured in highly specialized shapes, including coils, blocks, and panoramic designs, to meet unique process requirements.

Understanding the Trade-offs

MoSi2 elements offer exceptional performance, but they come with specific operational considerations that are crucial for ensuring longevity and reliability.

High-Temperature Performance

These elements are valued for their ability to operate continuously at very high temperatures, with element surface temperatures reaching up to 1900°C in some cases. They last significantly longer than Silicon Carbide (SiC) elements when operated consistently above 1500°C.

Contamination Risk

MoSi2 elements are susceptible to chemical attack and contamination. Care must be taken to properly dry any materials, such as colored zirconia or paints, introduced into the furnace to prevent the release of vapors that can degrade the element's protective silica layer.

Wiring and Maintenance

Elements are typically wired in a series circuit. A key advantage is that old and new elements have compatible resistance, allowing for individual replacements without needing to change the entire set. Their robust oxidation resistance and auto-repairing silica layer result in minimal maintenance, lowering overall operating costs.

How to Specify the Right Element

Your specific goal will determine which dimensional parameters are most important for you to focus on.

- If your primary focus is designing a new furnace: Begin with your required heating chamber volume and target temperature, which will help you calculate the necessary total heating length (Le) and select an appropriate element shape and spacing (A).

- If your primary focus is replacing existing elements: Precisely measure the D1, D2, Le, Lu, and A of your current elements. These measurements are your direct replacement specifications for ordering.

- If your primary focus is maximizing heating power in a limited space: Consider W-shape elements, as they offer greater power density for a given footprint compared to standard U-shapes.

Understanding these core parameters empowers you to select or design a heating solution perfectly matched to your high-temperature application.

Summary Table:

| Dimension | Description | Standard Range |

|---|---|---|

| D1 (Heating Zone Diameter) | Diameter of the hot leg, affects power density | 3mm to 12mm |

| D2 (Terminal Zone Diameter) | Diameter of the cold leg, prevents overheating | 6mm to 24mm |

| Le (Heating Zone Length) | Length of the active heating section | 80mm to 1500mm |

| Lu (Terminal Zone Length) | Length for insulation and connections | 80mm to 2500mm |

| A (Shank Spacing) | Center-to-center distance for U/W shapes | 25mm to 100mm |

Ready to enhance your laboratory's high-temperature processes with tailored MoSi2 heating elements? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, boosting efficiency and reliability. Contact us today for expert guidance and a quote!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer