The primary benefit of low thermal mass in MoSi2 (molybdenum disilicide) heating elements is the ability to achieve exceptionally rapid and precise temperature control. This property allows these elements to heat up quickly using less energy and to closely follow temperature setpoints without significant overshooting or undershooting, which is critical for sensitive industrial processes.

Low thermal mass is not simply about heating up faster. It fundamentally translates to greater process efficiency, product quality, and cost savings by minimizing wasted energy and enabling the rapid thermal cycling required in modern high-temperature furnaces.

The Physics of Low Thermal Mass: Speed and Efficiency

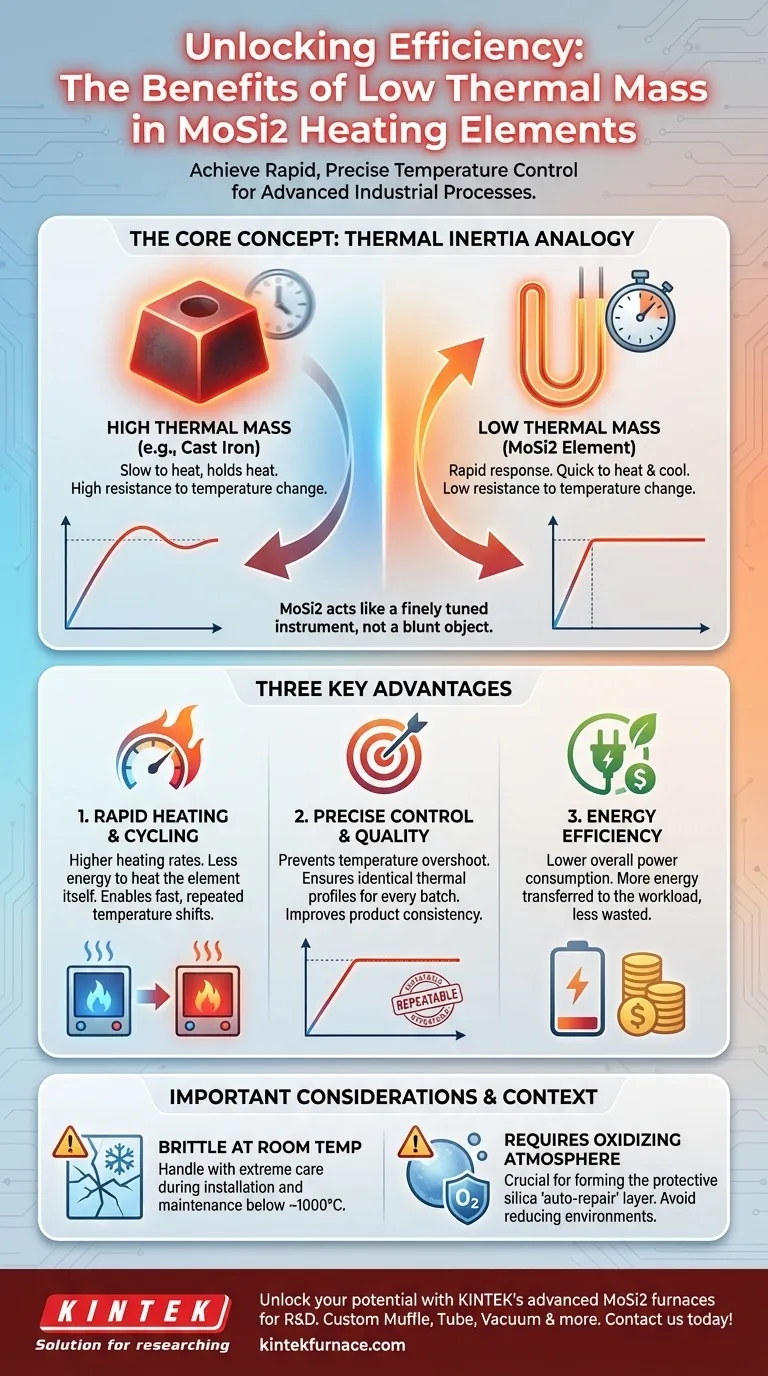

At its core, the advantage of low thermal mass is about responsiveness. It allows the heating element to change its temperature quickly in response to power input, acting more like a finely tuned instrument than a blunt object.

What is Thermal Mass?

Think of thermal mass as thermal inertia. It is an object's resistance to a change in temperature.

A massive, cast iron block has high thermal mass; it takes a long time and a lot of energy to heat up, but it also holds that heat for a long time.

Conversely, a thin wire has very low thermal mass. It heats up almost instantly when electricity is applied and cools down just as fast when the power is cut. MoSi2 elements behave much more like the thin wire.

The Impact on Heating Rate

Because MoSi2 elements have low thermal mass, they require less energy to raise their own temperature.

This means more of the electrical power is transferred directly to heating the furnace chamber and its workload, not wasted on heating the element itself. This results in high heating rates and lower overall power consumption.

The Impact on Cooling and Cycling

This responsiveness also applies to cooling. When power is reduced or cut, the low-mass element cools down quickly.

This capability is essential for rapid thermal cycling, where a process requires fast and repeated shifts between high and low temperatures. This is something that high-mass elements simply cannot do efficiently.

Why Precise Control Matters in High-Temperature Applications

In industrial and laboratory settings, temperature is not just about being "hot." It's about being at the exact right temperature at the exact right time. This is where the benefits of low thermal mass become critical.

Preventing Temperature Overshoot

Overshoot occurs when a heating system surpasses its target temperature before settling down. This can be disastrous for sensitive materials, ruining products or entire research batches.

The rapid response of MoSi2 elements allows a temperature controller to cut power just before the setpoint is reached, preventing the element's stored heat from pushing the temperature too high.

Improving Process Repeatability

For manufacturing processes like the heat treatment of metals or the sintering of ceramics, consistency is key to quality.

The precise control offered by low-mass elements ensures that the thermal profile of every batch is identical. This leads to predictable and repeatable product outcomes, reducing defects and waste.

Enabling Complex Thermal Profiles

Modern material science often demands complex heating and cooling profiles with multiple ramps and soaks.

The agility of low thermal mass elements allows the furnace to accurately track these complex instructions, something that sluggish, high-mass systems cannot achieve.

Understanding the Trade-offs and Context

No material is perfect for every situation. Understanding the full operational context of MoSi2 elements is key to using them effectively.

Brittleness at Room Temperature

While incredibly strong at their operating temperatures above 1000°C, MoSi2 elements are brittle and fragile at room temperature. They must be handled with care during installation and furnace maintenance.

The Critical Role of the Protective Layer

MoSi2 elements achieve their long life at extreme temperatures by forming a thin, protective layer of silica (glass) on their surface. This "auto-repair" function requires an oxidizing atmosphere (an environment with oxygen).

Using these elements in reducing atmospheres can damage this protective layer and significantly shorten their lifespan.

Element Mass vs. Material Density

The term "low thermal mass" refers to the behavior of the finished element, which is typically formed into thin, U-shaped rods. While the material itself is relatively dense, its shape results in a low total mass, enabling its signature rapid response.

Making the Right Choice for Your Goal

Leveraging the benefits of low thermal mass depends on aligning its properties with your primary process objective.

- If your primary focus is process speed and throughput: The rapid heating rates and ability to perform fast thermal cycling will directly increase the number of batches you can run.

- If your primary focus is product quality and consistency: The precise temperature control, prevention of overshoot, and process repeatability are the most valuable benefits.

- If your primary focus is energy efficiency: The low power consumption, resulting from less energy being wasted on heating the elements themselves, will lead to significant operational cost savings.

Ultimately, understanding the low thermal mass of MoSi2 elements empowers you to design and operate more efficient, responsive, and reliable high-temperature systems.

Summary Table:

| Benefit | Description |

|---|---|

| Rapid Heating | Achieves high heating rates with less energy wasted on element heating. |

| Precise Control | Prevents temperature overshoot and enables accurate tracking of setpoints. |

| Energy Efficiency | Lowers power consumption by minimizing energy used for element temperature changes. |

| Fast Thermal Cycling | Allows quick shifts between temperatures, essential for modern processes. |

| Improved Repeatability | Ensures consistent thermal profiles for better product quality and reduced defects. |

Unlock the full potential of your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with MoSi2-equipped furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures these solutions precisely meet your unique experimental needs, delivering rapid heating, precise control, and energy savings. Contact us today to discuss how we can enhance your lab's efficiency and reliability!

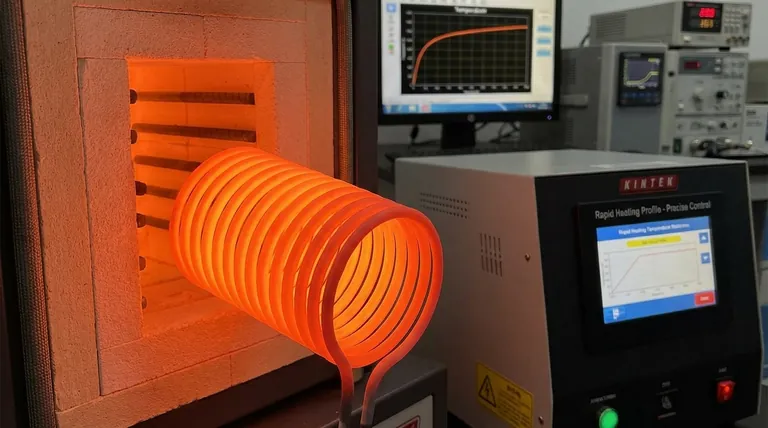

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights