The primary monitoring responsibility of a K-type thermocouple in a high-temperature carbonization furnace is to provide real-time feedback on internal temperature gradients to a closed-loop control system. Positioned along the horizontal axis, these sensors are critical for maintaining the precise thermal environment required to dictate the physical and chemical properties of the final biochar product.

By continuously tracking thermal gradients, the K-type thermocouple links the physical heat of the furnace to the quality control of the biochar, ensuring temperatures remain within the narrow window required for specific yields and surface area characteristics.

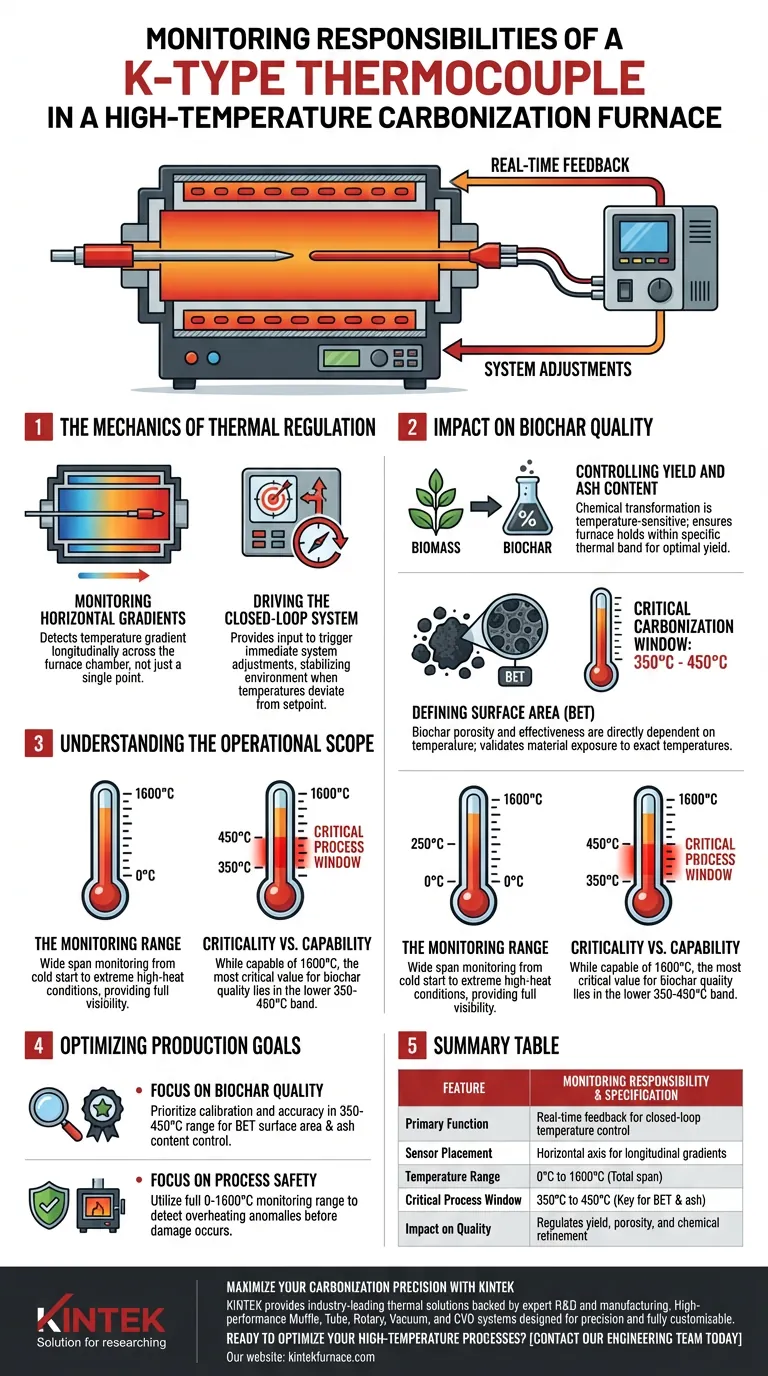

The Mechanics of Thermal Regulation

Monitoring Horizontal Gradients

The thermocouple is not merely measuring a single point of heat; it is responsible for detecting the temperature gradient across the furnace.

These high-precision sensors are positioned along the horizontal axis of the furnace. This placement allows operators to understand how heat is distributing longitudinally through the carbonization chamber.

Driving the Closed-Loop System

The data collected by the thermocouple serves a functional, active role rather than a passive one.

It provides the necessary input for the closed-loop temperature control system. If the temperature deviates from the setpoint, the thermocouple's signal triggers immediate system adjustments to stabilize the environment.

Impact on Biochar Quality

Controlling Yield and Ash Content

The chemical transformation of biomass into biochar is highly sensitive to temperature.

Specific characteristics, such as yield and ash content, rely on maintaining the process within a specific thermal band. The thermocouple ensures the furnace holds steady within this critical operational range.

Defining Surface Area (BET)

The BET surface area—a measure of the biochar's porosity and effectiveness—is directly dependent on the carbonization temperature.

The primary reference notes that critical carbonization typically occurs between 350°C and 450°C. The thermocouple's responsibility is to validate that the material is exposed to exactly these temperatures to achieve the desired surface structure.

Understanding the Operational Scope

The Monitoring Range

According to the system specifications, these thermocouples are tasked with monitoring a wide operational span, typically covering 0 to 1600°C.

This wide range ensures the sensor can track the furnace from a cold start up to extreme high-heat conditions, providing visibility throughout the entire heating cycle.

Criticality vs. Capability

While the sensor monitors the full 0-1600°C spectrum, its most critical value lies in the lower 350-450°C band.

Operators must recognize that while the sensor can read higher temperatures, the success of the biochar production relies entirely on the accuracy of the reading within that narrower processing window.

Optimizing Production Goals

To effectively utilize K-type thermocouples in your carbonization process, align your monitoring strategy with your specific production targets:

- If your primary focus is Biochar Quality: Prioritize calibration and accuracy in the 350-450°C range to strictly control BET surface area and ash content.

- If your primary focus is Process Safety: Utilize the full 0-1600°C monitoring range to detect overheating anomalies along the horizontal axis before they damage the furnace structure.

Success in carbonization ultimately relies on trusting the thermocouple to act as the precise bridge between raw heat and chemical refinement.

Summary Table:

| Feature | Monitoring Responsibility & Specification |

|---|---|

| Primary Function | Real-time feedback for closed-loop temperature control |

| Sensor Placement | Horizontal axis to detect longitudinal temperature gradients |

| Temperature Range | 0°C to 1600°C (Total span) |

| Critical Process Window | 350°C to 450°C (Key for BET surface area & ash content) |

| Impact on Quality | Regulates yield, porosity, and chemical refinement of biochar |

Maximize Your Carbonization Precision with KINTEK

Don't let temperature fluctuations compromise your biochar quality. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. Our high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems are designed for precision and can be fully customized to meet your unique lab or industrial requirements.

Ready to optimize your high-temperature processes? Contact our engineering team today to discover how KINTEK's customizable furnaces and sensor technologies can enhance your production efficiency and material quality.

Visual Guide

References

- Hesham A. Farag, Reham M. Kamel. DEVELOPMENT AND EVALUATION OF A CONTINUOUS FLOW BIOCHAR UNIT USING RICE HUSK BIOMASS. DOI: 10.35633/inmateh-72-03

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is it important to ground the thermocouple properly? Ensure Accurate Temperature Readings in Noisy Environments

- Why are both external and internal thermocouples required for pyrolysis? Optimize Your Thermal Reaction Monitoring

- How convenient are MoSi2 heating elements to install and maintain? Maximize Uptime with Easy Hot-Swappable Elements

- Why is ductility a necessary property for heating elements? Ensure Reliability and Manufacturing Success

- What ceramic materials are commonly used for heating elements? Discover the Best for Your High-Temp Needs

- What materials are commonly used in high-temperature heating elements? Explore Top Choices for Durability and Efficiency

- What is the maximum temperature for a quartz heating element? Up to 2400°C in Open Air

- What are the common types of heating element designs? Discover the Best Fit for Your Heating Needs