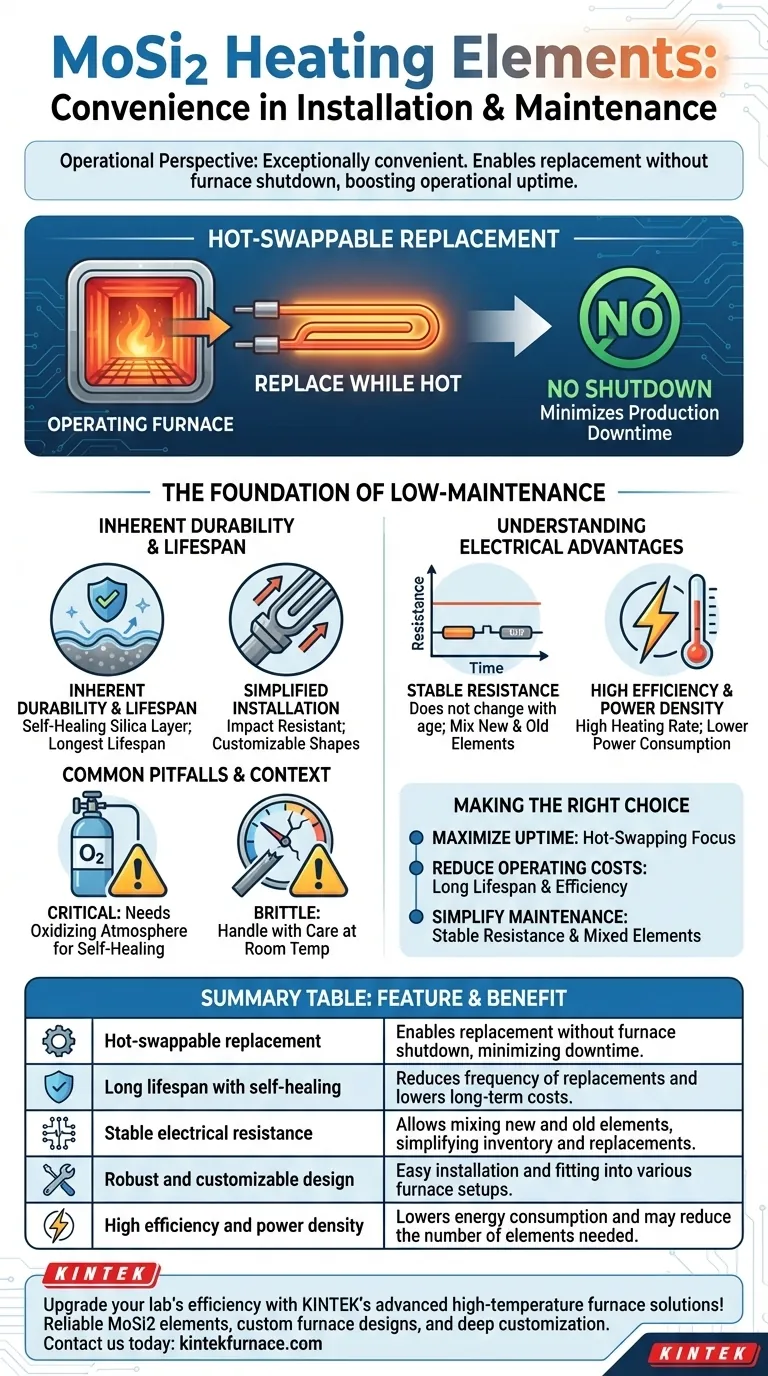

From an operational perspective, Molybdenum Disilicide (MoSi2) heating elements are exceptionally convenient to install and maintain. Their design allows for straightforward replacement, and most importantly, this can often be done without shutting down the furnace, which is a significant advantage for continuous production environments.

The core convenience of MoSi2 elements is not just their ease of handling, but their direct impact on operational uptime. The ability to replace elements while the furnace is hot, combined with their long lifespan, fundamentally minimizes costly production downtime and reduces overall maintenance burdens.

The Foundation of Low-Maintenance Operation

The convenience of MoSi2 elements stems from a combination of their physical durability, long operational life, and unique electrical properties. These factors work together to reduce both the frequency and complexity of maintenance tasks.

The Impact of Hot-Swappable Replacement

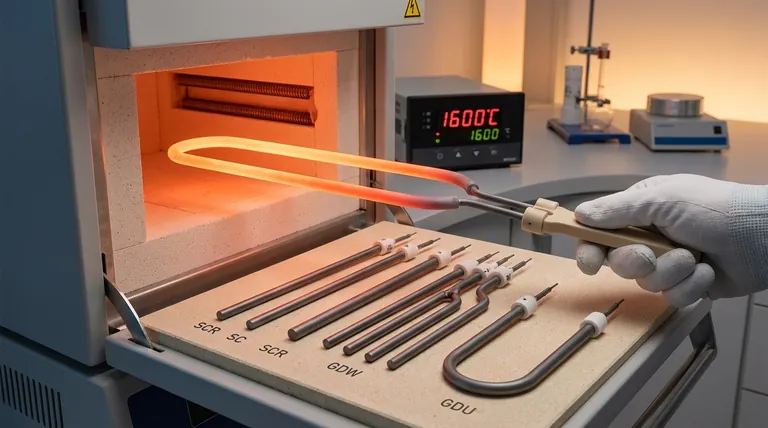

The single most important feature for maintenance convenience is that MoSi2 elements can be replaced while the furnace remains at operating temperature.

This "hot-swapping" capability eliminates the need for lengthy and costly cool-down and heat-up cycles that are required for other element types.

For any facility focused on maximizing throughput, this feature translates directly into less production downtime and higher operational efficiency.

Inherent Durability and Lifespan

MoSi2 elements possess the longest inherent lifespan among common metallic and ceramic electric heating elements.

This longevity is enhanced by a unique self-healing property. In an oxidizing atmosphere, the element forms a protective layer of silica glass on its surface that automatically repairs minor cracks and imperfections, extending its service life.

A longer lifespan means replacements are less frequent, lowering both material and labor costs over time.

Simplified Installation and Handling

MoSi2 elements are manufactured with a special joint molding process that gives them strong impact resistance compared to more fragile ceramic elements. This makes them more robust and less prone to damage during shipping and installation.

Furthermore, they are available in a wide variety of standard and customizable shapes, allowing them to be easily fitted into new or existing furnace designs without major modifications.

Understanding the Electrical Advantages

The electrical characteristics of MoSi2 elements play a critical role in simplifying their maintenance and replacement over the long term.

The Benefit of Stable Resistance

Unlike many other heating elements, the electrical resistance of MoSi2 does not change significantly as it ages.

This stable resistance is a crucial advantage because it allows you to connect new replacement elements in series with older, existing elements without causing electrical imbalances.

You can replace only the single failed element rather than an entire set, simplifying spare parts inventory and reducing replacement costs.

High Efficiency and Power Density

These elements feature a high heating rate and low power consumption. Their ability to handle high watt loadings means fewer elements may be required to achieve a target temperature, potentially simplifying the overall furnace design and wiring.

Common Pitfalls and Operational Context

While MoSi2 elements are robust, their peak performance and self-healing capabilities are dependent on a specific environment.

The Critical Role of an Oxidizing Atmosphere

The protective silica layer that gives MoSi2 its longevity and self-healing properties can only form in the presence of oxygen.

Using these elements in a reducing atmosphere (like hydrogen or nitrogen) or in a vacuum at high temperatures can lead to rapid degradation and premature failure.

Physical Brittleness at Low Temperatures

Like many ceramics, MoSi2 elements are relatively brittle at room temperature. Care must be taken during installation to avoid mechanical shock or stress that could cause them to fracture.

Making the Right Choice for Your Goal

When evaluating MoSi2 elements, align their benefits with your primary operational objective.

- If your primary focus is maximizing production uptime: The ability to replace elements without a furnace shutdown is the most significant advantage, directly minimizing lost production hours.

- If your primary focus is reducing long-term operating costs: The combination of a long lifespan, low power consumption, and the ability to replace single elements reduces expenditures on materials, labor, and energy.

- If your primary focus is simplifying maintenance workflow: The stable resistance allows for mixing new and old elements, drastically simplifying replacement procedures and spare part management.

Ultimately, the design of MoSi2 elements translates directly into a more efficient, predictable, and cost-effective high-temperature process.

Summary Table:

| Feature | Benefit |

|---|---|

| Hot-swappable replacement | Enables element replacement without furnace shutdown, minimizing production downtime |

| Long lifespan with self-healing | Reduces frequency of replacements and lowers long-term costs |

| Stable electrical resistance | Allows mixing new and old elements, simplifying inventory and replacements |

| Robust and customizable design | Easy installation and fitting into various furnace setups |

| High efficiency and power density | Lowers energy consumption and may reduce the number of elements needed |

Upgrade your lab's efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable MoSi2 heating elements and custom furnace designs, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, boosting uptime and cutting costs. Contact us today to discuss how we can optimize your high-temperature processes!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the advantages of U-shaped heating elements (SIC Rods)? Unlock Installation Ease and High-Temp Performance

- How does a digital temperature controller function in phenolic curing? Master Multi-Stage Thermal Protection

- Where are GC Type Silicon Carbide Heating Elements extensively used? Ideal for Glass, Chemicals, and Electronics

- What properties should a material have to be suitable for heating elements? Key Traits for High-Temperature Performance

- What are some industrial applications of SiC heating elements? Boost Efficiency in High-Temp Processes

- How do thick film heating elements differ from other types? Discover Speed, Precision, and Efficiency

- Why is resistance to oxidation a critical property for a heating element? Prevent Premature Failure

- What are the typical shapes of MoSi2 heating elements? Explore U, W, L Shapes for Optimal Furnace Performance