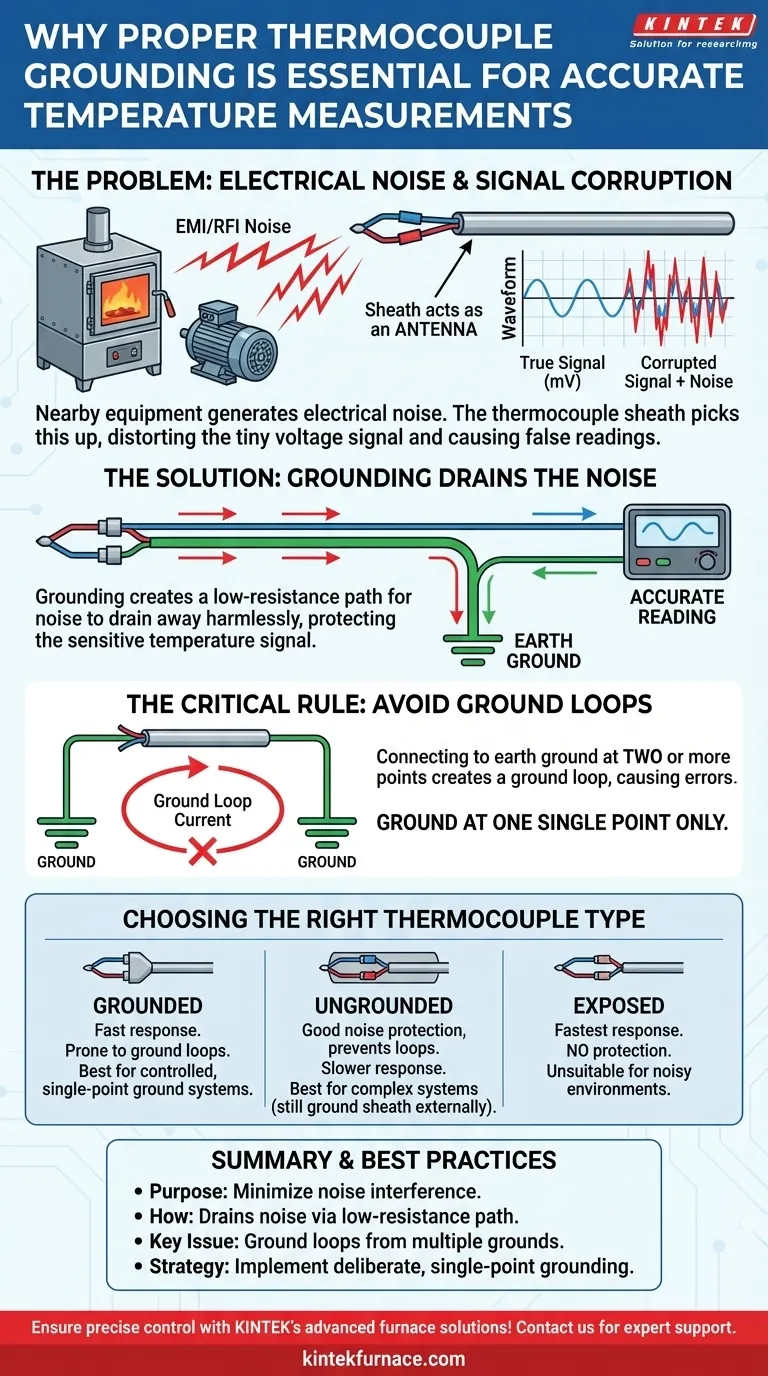

Properly grounding a thermocouple is essential for ensuring accurate and reliable temperature measurements. This practice minimizes the impact of electrical interference, or "noise," which can corrupt the thermocouple's very small voltage signal and lead to significant errors, particularly in electrically noisy industrial environments like those with furnaces.

A thermocouple's metal sheath acts like an antenna, picking up stray electrical noise. Grounding provides a safe, low-resistance path for this noise to drain away, preventing it from distorting the sensitive temperature signal and ensuring your measurement lettura is accurate.

The Root of the Problem: Electrical Noise

To understand why grounding is critical, you must first understand the environment thermocouples operate in and the nature of their signal.

What is Electrical Noise?

Electrical noise, पुलिस महानिरीक्षक (EMI) या रेडियो-आवृत्ति हस्तक्षेप (RFI), is unwanted electrical energy. It is generated by nearby power lines, motors, heaters, relays, and other industrial equipment.

This ambient energy can be "induced" onto any conductive material, much like a radio antenna concentração up a signal.

Why Thermocouples are Vulnerable

A thermocouple works by generating a tiny voltage—measured in millivolts (mV)—that corresponds to a specific temperature. This signal is inherently weak and low-energy.

When electrical noise induces a voltage onto the thermocouple's wiring, this noise voltage can be similaire in magnitude to the actual temperature signal. The measuring instrument sees the combination of the two, leading to a false, and often fluctuating, temperature reading.

How Grounding Creates a Clean Signal

Grounding is the active solution to protect the thermocouple's vulnerable signal from the disruptive effects of electrical noise.

The Sheath as an "Antenna"

Most industrial thermocouples are housed in a metal tube বা "sheath" for protection. While physically robust, this conductive sheath is સેવા an excellent antenna for picking up the ambient electrical noise in a plant.

Creating a Path of Least Resistance

Grounding involves connecting this metal sheath to a known earth ground. This creates a dedicated, low-resistance path for any induced noise currents.

Instead of traveling down the thermocouple wires and interfering with the measurement signal, the noise 에너지 flows harmlessly to the ground. This process is often called "draining the shield" or "draining the noise."

The Result: An Accurate Reading

With the electrical noise diverted to ground, the measuring instrument receives a clean, stable millivolt signal that accurately represents the true temperature. This is especially critical in high-temperature applications, such as furnaces, where powerful heating elements generate significant electrical interference.

Understanding the Trade-offs and Common Pitfalls

While grounding is a powerful tool, improper implementation can create new problems. The most common issue is the ground loop.

The Danger of Ground Loops

A ground loop occurs when a measurement circuit is connected to earth ground at two or more different points. Small differences in ground potential между these two points can cause a current to flow through the thermocouple wires.

This current पुलिस another source of error, funzionamento defeating the purpose of grounding. The cardinal rule is to ground the thermocouple circuit at one single point only.

Choosing the Right Thermocouple Type

Thermocouples come in three common junction types, each with different grounding implications:

- Grounded: The thermocouple junction is welded directly to the inside of the protective sheath. This provides a very fast response time but makes the system inherently susceptible to ground loops if not installed carefully.

- Ungrounded: The junction is isolated from the sheath. This provides good noise protection and prevents ground loops, but has a slower response time. You can still ground the sheath externally for noise shielding.

- Exposed: The junction is outside the sheath entirely. This offers the fastest response but no protection and is unsuitable for noisy industrial environments.

Making the Right Choice for Your Application

Use this guidance to determine your grounding strategy.

- If your primary focus is maximum noise immunity in a controlled system: Use a grounded junction thermocouple and ensure it is the only ground point in the entire measurement loop, from sensor to controller.

- If your primary focus is preventing ground loops in a complex system: Use an ungrounded thermocouple. You can (and should) still connect the external sheath to ground to drain noise, but the internal isolation prevents differenza in ground potential from affecting the signal.

- If you are experiencing erratic readings: Immediately check your system for ground loops. Disconnect grounds 하나 by one to find the source of the problem, and re-establish a single, high-quality ground connection.

By implementing a deliberate, single-point grounding strategy, you ensure the integrity of your measurement and the reliability of your process.

Summary Table:

| Aspect | Key Information |

|---|---|

| Purpose | Minimizes electrical noise interference for accurate temperature readings |

| How It Works | Grounding drains noise via a low-resistance path, protecting the weak thermocouple signal |

| Common Issues | Ground loops from multiple grounding points can cause measurement errors |

| Thermocouple Types | Grounded (fast response, prone to loops), Ungrounded (good noise protection), Exposed (fast, no protection) |

| Best Practices | Use single-point grounding; choose type based on noise immunity vs. response time needs |

Ensure precise temperature control in your lab with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Proper thermocouple grounding is key to accuracy—let us help you optimize your setup. Contact us today for expert support and reliable equipment!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation