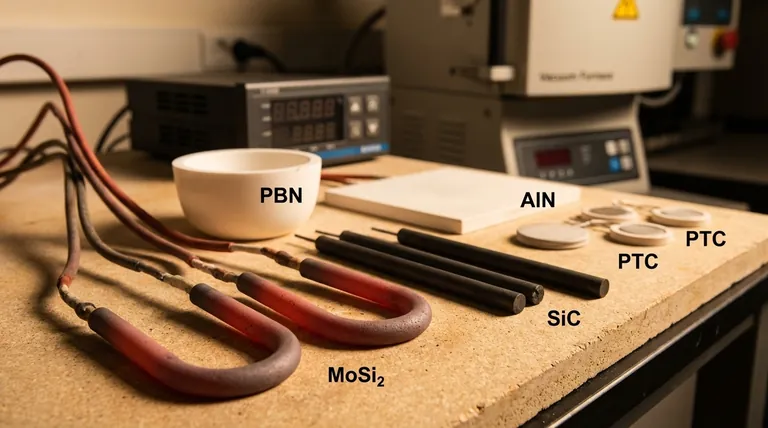

In short, the most common ceramic materials used for heating elements are Molybdenum Disilicide (MoSi₂), Silicon Carbide (SiC), Pyrolytic Boron Nitride (PBN), Aluminum Nitride (AlN), and specialized Positive Temperature Coefficient (PTC) ceramics. Each is selected for its unique combination of maximum temperature, chemical resistance, and specific thermal properties.

Choosing the right ceramic heating material is less about finding the one that gets hottest and more about matching a material's unique performance profile—its temperature limits, purity, and durability—to the precise demands of your application.

The Role of Ceramics in Heating Elements

Before comparing materials, it's critical to understand that "ceramic heater" can mean one of two things. This distinction is fundamental to selecting the right technology.

As the Resistive Element

In high-performance applications, the ceramic material itself is conductive and acts as the heating element. Materials like Molybdenum Disilicide and Silicon Carbide generate heat when electricity passes through them, allowing for extremely high operating temperatures.

As the Insulator and Thermal Conductor

More commonly, a ceramic material acts as a robust housing. It electrically insulates a metallic heating wire (like Nichrome) while efficiently conducting heat to the surrounding environment. In this role, the ceramic provides structural integrity, corrosion resistance, and thermal stability that the metal wire alone cannot.

A Breakdown of Key Ceramic Materials

Each advanced ceramic material offers a distinct set of advantages tailored to specific industrial, scientific, or commercial needs.

Molybdenum Disilicide (MoSi₂)

MoSi₂ is the champion for extreme heat, capable of operating in air at temperatures up to 1850°C (3362°F). It forms a protective silica layer that prevents further oxidation at high temperatures.

Its primary application is in high-temperature laboratory and production furnaces for metallurgy, glass melting, and ceramic firing.

Silicon Carbide (SiC)

SiC is a highly durable workhorse known for its high operating temperature (up to 1625°C / 2957°F), rigidity, and excellent resistance to both oxidation and chemical corrosion.

It is often used in furnaces, as a radiant ignition source in gas appliances, and in applications involving harsh chemical environments.

Pyrolytic Boron Nitride (PBN)

PBN is an ultra-pure, man-made ceramic valued for its exceptional chemical inertness and thermal stability up to 1600°C (2912°F) in vacuum environments.

It is the material of choice for crucibles, coatings, and furnace components used in semiconductor manufacturing and molecular beam epitaxy (MBE), where preventing contamination is paramount.

Aluminum Nitride (AlN)

AlN stands out for its high thermal conductivity, allowing for very fast and uniform heating. While its maximum operating temperature is lower (around 600°C / 1112°F), its rapid response is ideal for applications requiring precise thermal cycling.

Common uses include heaters for soldering irons, water heating, and specialized equipment in the medical and aerospace industries.

Positive Temperature Coefficient (PTC) Ceramics

PTC ceramics are "smart" materials that self-regulate their temperature. As they approach a specific design temperature, their electrical resistance increases dramatically, reducing current flow and stabilizing heat output.

This makes them inherently safe from overheating. They are widely used in smaller appliances like space heaters, glue guns, and automotive components, typically operating below 1000°C (1832°F).

Understanding the Trade-offs: Ceramic vs. Metallic

Ceramic heating elements do not exist in a vacuum. They are often chosen over—or used in conjunction with—traditional metallic elements.

Why Choose Ceramic Elements?

Ceramic materials are the definitive choice for applications with one or more of the following requirements:

- Extreme Temperatures: For operating temperatures above 1400°C, materials like MoSi₂ and SiC are essential.

- Harsh Environments: When exposed to corrosive chemicals or oxidation, ceramics provide superior longevity.

- High Purity: In semiconductor or lab settings, the inert nature of PBN is non-negotiable.

- Specific Heat Profile: Materials like AlN for rapid cycling or PTC ceramics for self-regulation solve problems metals cannot.

When to Consider Metallic Elements

Traditional metallic alloys like Nichrome (Nickel-Chromium) and Kanthal (Iron-Chromium-Aluminum) remain dominant for a reason.

They are often the right choice for general-purpose heating where cost is a major driver, temperatures are moderate (below 1400°C), and ductility for forming wires and ribbons is an advantage. These are the elements you find in most consumer ovens, toasters, and dryers, typically insulated by a standard ceramic casing.

Making the Right Choice for Your Goal

Your final decision must be guided by the primary objective of your design.

- If your primary focus is reaching maximum temperatures: MoSi₂ is the clear choice for its ability to operate reliably above 1800°C.

- If your primary focus is durability and chemical resistance: SiC provides an excellent balance of high-temperature performance and resilience in demanding industrial settings.

- If your primary focus is absolute purity: PBN is the only option for applications like semiconductor processing where contamination cannot be tolerated.

- If your primary focus is inherent safety and self-regulation: PTC ceramics offer a built-in safety mechanism that simplifies design and prevents overheating.

- If your primary focus is rapid heating and thermal uniformity: AlN delivers exceptional thermal conductivity for applications that require quick and even temperature distribution.

By understanding these material profiles, you can select a heating element that delivers not just heat, but the precise performance, reliability, and safety your application demands.

Summary Table:

| Material | Max Temperature | Key Features | Primary Applications |

|---|---|---|---|

| Molybdenum Disilicide (MoSi₂) | 1850°C | Extreme heat resistance, forms protective silica layer | Metallurgy, glass melting, ceramic firing |

| Silicon Carbide (SiC) | 1625°C | Durable, oxidation and chemical corrosion resistant | Industrial furnaces, gas appliances |

| Pyrolytic Boron Nitride (PBN) | 1600°C | Ultra-pure, chemically inert, thermal stability | Semiconductor manufacturing, MBE |

| Aluminum Nitride (AlN) | 600°C | High thermal conductivity, rapid heating | Soldering irons, medical, aerospace |

| PTC Ceramics | 1000°C | Self-regulating, safe from overheating | Space heaters, glue guns, automotive |

Unlock the Full Potential of Your Laboratory with KINTEK's Advanced Heating Solutions

Are you struggling to find the right ceramic heating element for your high-temperature applications? At KINTEK, we specialize in providing cutting-edge high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing capabilities, we offer a comprehensive product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your specific experimental requirements, whether you're in research, industrial processing, or semiconductor development.

Don't let material limitations hold you back—contact us today to discuss how our expertise can enhance your lab's efficiency and reliability. Reach out now via our contact form and let's build the perfect solution together!

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the primary applications of Molybdenum Disilicide (MoSi2) heating elements in furnaces? Achieve High-Temp Excellence

- What is the temperature range where MoSi2 heating elements should not be used for long periods? Avoid 400-700°C to Prevent Failure

- What are the advantages of using molybdenum-disilicide heating elements for aluminum alloy processing? (Rapid Heating Guide)

- What is the temperature range for MoSi2 heating elements? Maximize Lifespan in High-Temp Applications

- What role do MoSi2 heating elements play in 1500 °C experiments? Key to Stability and Precision