In short, ductility is essential because it allows the raw heating alloy to be drawn into a thin wire and then bent or coiled into a specific shape without breaking. This manufacturability is non-negotiable for creating functional heating elements that can fit inside appliances and distribute heat effectively.

While we often focus on a heating element's electrical resistance and heat tolerance, its physical form is equally critical. Ductility is the key mechanical property that makes it possible to manufacture an element into the precise, often complex, shape required for its application, ensuring both efficiency and reliability.

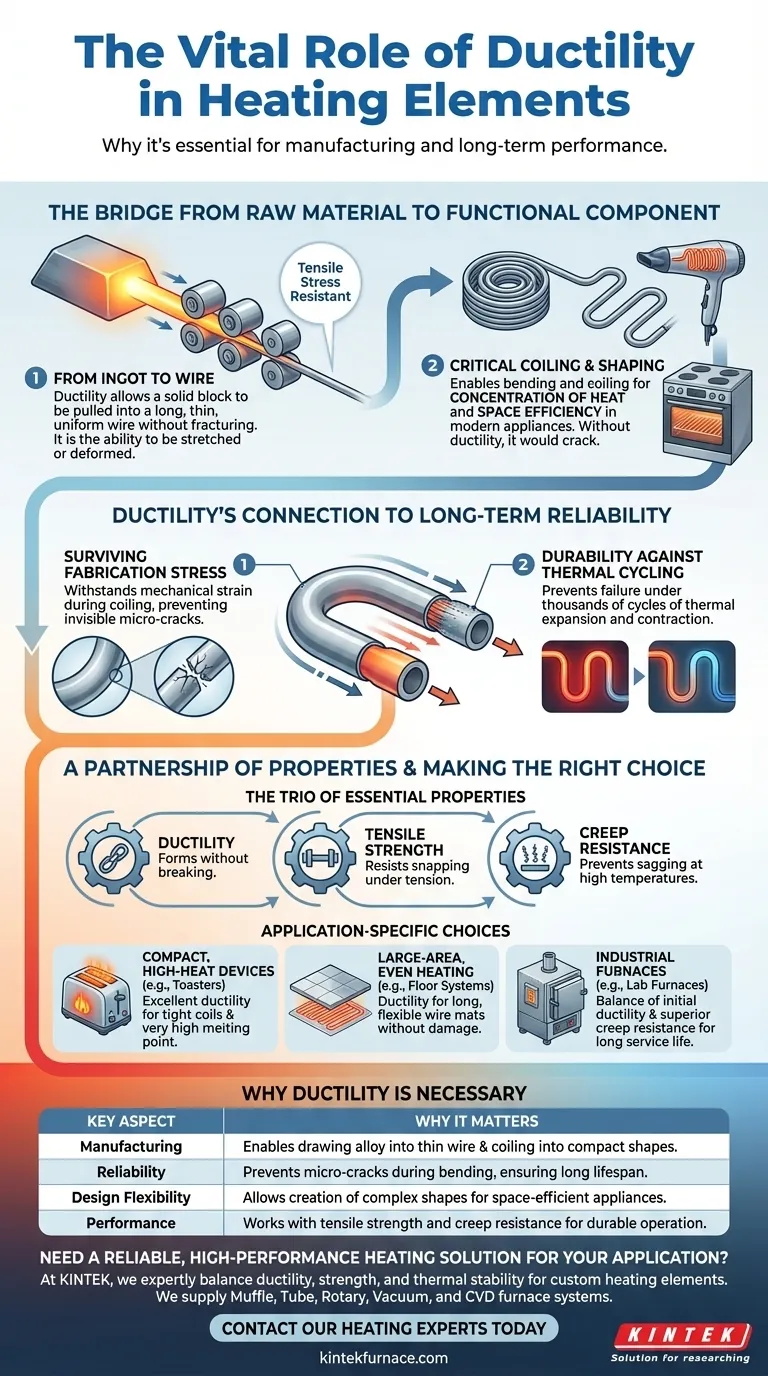

The Bridge From Raw Material to Functional Component

A lump of a heating alloy like Nichrome is useless on its own. Its value is only realized when it can be shaped into a component that fits a specific purpose, whether in a toaster or an industrial furnace. Ductility is the property that enables this transformation.

From Ingot to Wire

The very first step in manufacturing most heating elements is drawing the alloy through a series of dies to create a wire of a specific gauge.

Ductility is the material's ability to be stretched or deformed without fracturing. This property is what allows a solid block of metal to be pulled into a long, thin, uniform wire. A brittle material would simply snap under the immense tensile stress of this process.

The Critical Role of Coiling and Shaping

Heating elements are rarely used as straight wires. They are almost always coiled, bent, or arranged into a serpentine pattern.

This shaping accomplishes two critical goals:

- Concentration of Heat: Coiling a long wire into a small space allows a significant amount of heat to be generated in a compact area.

- Space Efficiency: It enables the element to fit inside the tight confines of modern appliances like hair dryers, ovens, and kettles.

Without ductility, any attempt to bend the wire into these dense, efficient shapes would cause it to crack and fail immediately.

Ductility's Connection to Long-Term Reliability

While ductility is primarily a manufacturing concern, it has direct implications for the element's operational lifespan and durability.

Surviving the Stress of Fabrication

The process of coiling and bending induces significant mechanical stress into the material. A ductile material can withstand this strain, ensuring no micro-cracks or weak points are created.

These invisible defects, if present, would become failure points once the element is subjected to thousands of cycles of thermal expansion and contraction during normal use.

A Partnership of Properties

Ductility does not work in isolation. It is part of a trio of essential mechanical properties required for a high-performance heating element.

- Ductility: Allows the wire to be formed without breaking.

- Tensile Strength: Ensures the wire doesn't snap under tension during manufacturing or installation.

- Creep Resistance: Prevents the element from sagging, stretching, or deforming over time when held at high operating temperatures.

An element must possess all three to be successfully manufactured and to operate reliably for years.

Understanding the Trade-offs

No material property is absolute. The choice of a heating alloy is always an engineered compromise designed to meet the demands of a specific application.

The Balance with Strength

Generally, as a material's ductility increases, its ultimate tensile strength may decrease. Engineers select alloys that strike a precise balance—ductile enough to be easily formed, but strong enough to hold that form and resist physical stress.

The Impact of High Temperatures

The initial ductility of the material is for manufacturing. However, the alloy must also resist becoming brittle after prolonged exposure to extreme heat. Some materials can "age" and lose ductility, making them susceptible to fracture from vibration or physical shock. This is why resistance to high-temperature oxidation and thermal stability are just as crucial.

Making the Right Choice for Your Goal

The required level of ductility is directly tied to the final application of the heating element.

- If your primary focus is compact, high-heat devices (like toasters or heat guns): You need a material with excellent ductility to be formed into extremely tight coils, combined with a very high melting point.

- If your primary focus is large-area, even heating (like a floor heating system): Ductility is crucial for producing long, flexible wire mats that can be installed over wide surfaces without damage.

- If your primary focus is industrial furnaces with long service life: The ideal material balances initial ductility for fabrication with superior creep resistance to prevent element sagging and failure at constant, extreme temperatures.

Ultimately, ductility is the foundational property that allows a heating alloy's electrical potential to be realized in a reliable physical form.

Summary Table:

| Key Aspect | Why Ductility is Necessary |

|---|---|

| Manufacturing | Enables drawing alloy into thin wire and coiling into compact shapes. |

| Reliability | Prevents micro-cracks during bending, ensuring a long operational lifespan. |

| Design Flexibility | Allows creation of complex shapes (serpentine, coils) for space-efficient appliances. |

| Performance | Works with tensile strength and creep resistance for durable, high-temperature operation. |

Need a reliable, high-performance heating solution for your application?

At KINTEK, we understand that the right heating element is critical to your system's efficiency and longevity. Our expert R&D and manufacturing team specializes in creating custom heating elements with the perfect balance of ductility, strength, and thermal stability for your unique needs.

We supply Muffle, Tube, Rotary, Vacuum, and CVD furnace systems, all backed by deep material science expertise.

Contact our heating experts today to discuss how we can provide a durable, custom heating solution for your lab or industrial process.

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the primary applications of MoSi2 heating elements in research? Achieve Reliable High-Temp Control for Material Synthesis

- How can high temperature heating elements be customized for different applications? Tailor Elements for Peak Performance

- What ceramic materials are commonly used for heating elements? Discover the Best for Your High-Temp Needs

- What are the primary applications of Molybdenum Disilicide (MoSi2) heating elements in furnaces? Achieve High-Temp Excellence

- What role do MoSi2 heating elements play in 1500 °C experiments? Key to Stability and Precision