At its core, customizing a high-temperature heating element involves strategically altering its material composition, physical geometry, and electrical characteristics. This process allows the element to be precisely tailored to a specific piece of equipment or industrial process, such as brazing, sintering, or hardening. The goal is to maximize thermal efficiency, ensure process purity, and extend the operational life of the component.

The most critical aspect of customization is not simply making an element fit a space, but aligning its fundamental material properties with the specific temperature, atmosphere, and performance demands of your application. This choice dictates everything from energy efficiency to the final quality of your product.

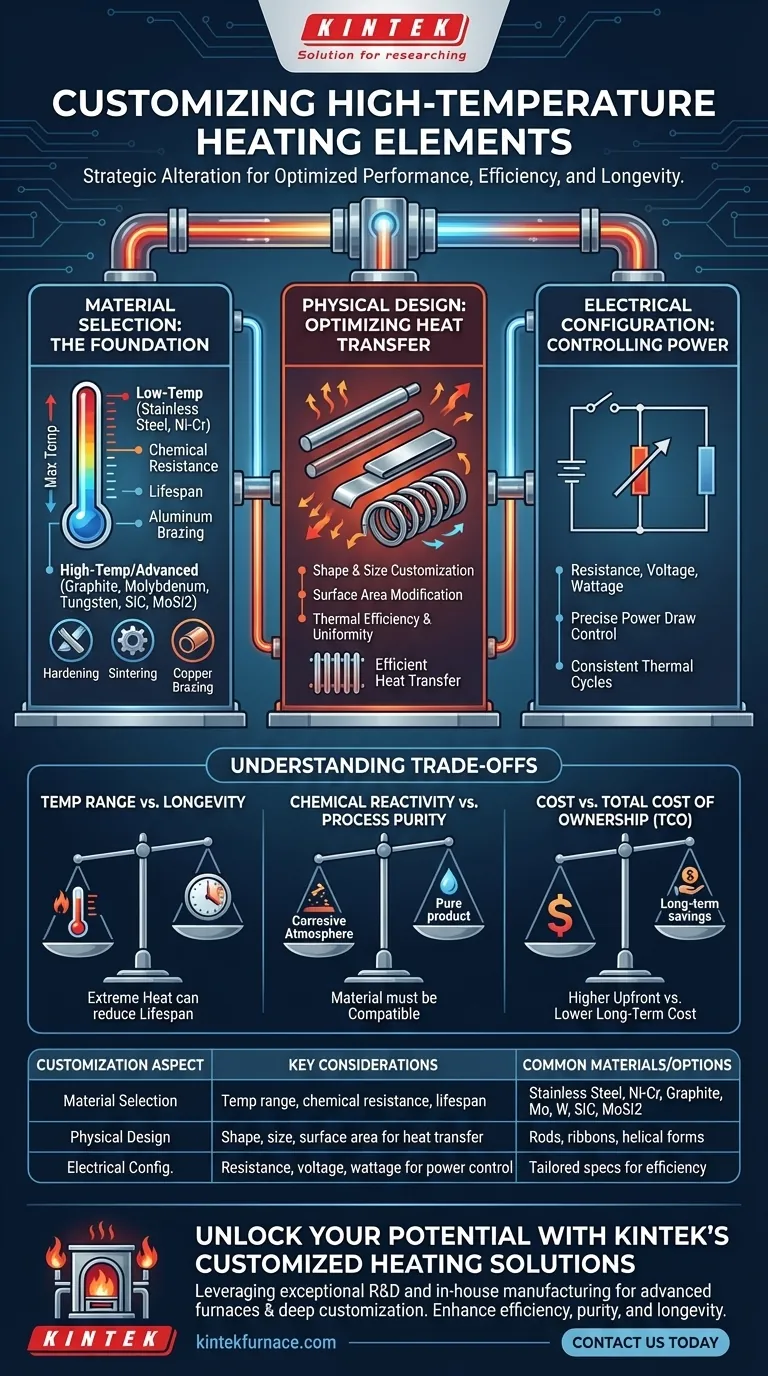

The Core Pillars of Customization

To achieve optimal performance, customization focuses on three distinct but interconnected areas. Each must be considered in the context of your specific operational goals.

Material Selection: The Foundation of Performance

The material is the single most important choice, as it defines the element's maximum operating temperature, its chemical resistance, and its overall lifespan.

Materials like stainless steel and nickel-chromium alloys are effective and economical for lower-temperature applications, such as aluminum brazing, especially when operating at higher partial pressures.

For high-temperature processes like hardening, sintering, or copper brazing, advanced materials are required. Graphite, molybdenum, and tungsten are common choices, each offering distinct advantages in specific heat ranges and atmospheric conditions.

Ceramic-based elements provide unique benefits. Silicon Carbide (SiC) is renowned for exceptional durability and corrosion resistance, while Molybdenum Disilicide (MoSi2) features a unique self-healing capability where it forms a protective oxide layer at high temperatures.

Physical Design: Optimizing Heat Transfer

The shape and size of the heating element are customized to ensure it fits the physical constraints of your equipment and delivers heat exactly where it is needed.

This customization is critical for thermal efficiency. By modifying the element's surface area and form factor—such as creating rods, ribbons, or complex helical shapes—you can control the rate and uniformity of heat radiation and convection.

Think of it like the fins on a radiator. A larger or more intricate surface area allows for more efficient heat transfer into the surrounding environment or product, reducing energy waste and improving process consistency.

Electrical Configuration: Controlling Power and Heat

While not just a physical attribute, the element's electrical properties are a key point of customization. This includes its resistance, voltage rating, and wattage.

By tailoring these specifications, you can precisely control the power draw and heat output. This ensures the element operates efficiently within your system's power budget and delivers consistent, repeatable thermal cycles. This is fundamental to achieving reliable process results.

Understanding the Trade-offs

Selecting the "best" element is rarely straightforward. It requires balancing competing priorities and understanding the inherent compromises of each material and design.

Temperature Range vs. Longevity

Materials capable of reaching the highest temperatures, like tungsten, may have a shorter lifespan or become brittle under certain conditions compared to materials operating at lower temperatures. The constant thermal cycling at extreme heat introduces significant stress.

Chemical Reactivity vs. Process Purity

The element's material must be compatible with your process atmosphere. For example, a molybdenum element provides excellent high-temperature performance but can oxidize rapidly if not used in a vacuum or a protective atmosphere.

In contrast, a Silicon Carbide (SiC) element offers superior resistance to chemical attack and corrosion, making it a better choice for processes with reactive gases. This prevents contamination of the product and prolongs the element's life.

Cost vs. Total Cost of Ownership

High-performance materials like Molybdenum Disilicide (MoSi2) often carry a higher initial purchase price. However, their antioxidant and "auto-repair" functions can lead to a significantly longer service life and less downtime.

This superior durability and efficiency can result in a lower total cost of ownership over the element's lifespan, making the upfront investment a strategic decision for critical, high-volume operations.

Making the Right Choice for Your Application

Your specific process goal should be the primary driver of your customization choices.

- If your primary focus is extreme temperature and process purity (e.g., sintering): Prioritize refractory metals like tungsten or molybdenum, ensuring you have the correct protective atmosphere.

- If your primary focus is durability in a corrosive or oxidizing atmosphere: Choose a robust ceramic element like Silicon Carbide (SiC).

- If your primary focus is rapid thermal cycling with maximum uptime: Select Molybdenum Disilicide (MoSi2) for its self-healing properties and impact resistance.

- If your primary focus is cost-effective heating for lower-temperature processes: Standard nickel-chromium or stainless steel alloys offer reliable performance.

Ultimately, thoughtful customization transforms a heating element from a simple component into a strategic asset engineered for your success.

Summary Table:

| Customization Aspect | Key Considerations | Common Materials/Options |

|---|---|---|

| Material Selection | Temperature range, chemical resistance, lifespan | Stainless steel, Ni-Cr alloys, Graphite, Molybdenum, Tungsten, SiC, MoSi2 |

| Physical Design | Shape, size, surface area for heat transfer | Rods, ribbons, helical forms |

| Electrical Configuration | Resistance, voltage, wattage for power control | Tailored specs for efficiency |

Unlock the full potential of your high-temperature processes with KINTEK's customized heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs—enhancing thermal efficiency, process purity, and component longevity. Don't settle for one-size-fits-all; contact us today to discuss how we can engineer the perfect heating element for your application and drive your success!

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What types of molybdenum disilicide heating elements are available? Choose the Right Element for Your High-Temp Needs

- What are the primary applications of MoSi2 heating elements in research? Achieve Reliable High-Temp Control for Material Synthesis

- What are the key differences between SiC and MoSi2 heating elements in sintering furnaces? Choose the Right Element for Your High-Temp Needs

- What role do MoSi2 heating elements play in 1500 °C experiments? Key to Stability and Precision

- What is the temperature range for MoSi2 heating elements? Maximize Lifespan in High-Temp Applications