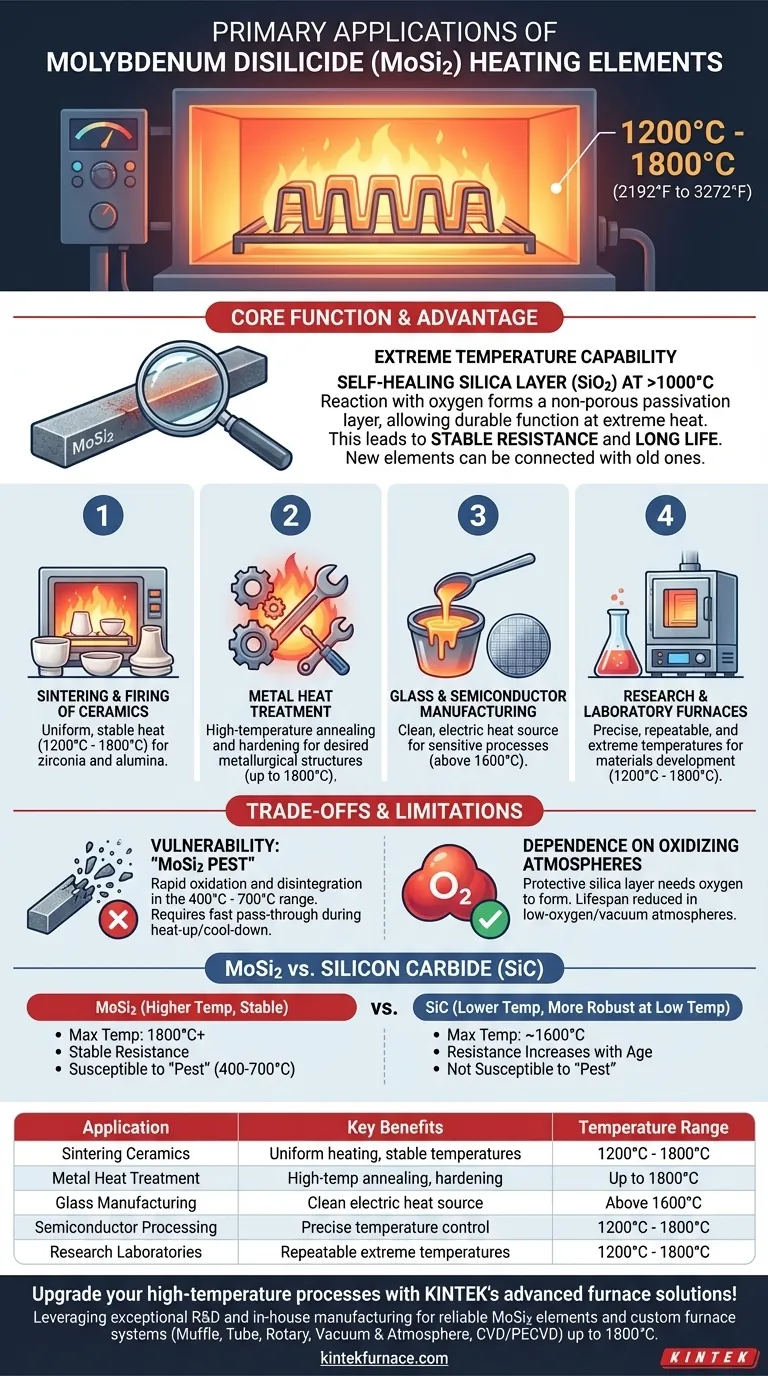

At their core, Molybdenum Disilicide (MoSi2) heating elements are the go-to solution for industrial and laboratory furnaces that must achieve extremely high operating temperatures. Their primary applications include the sintering of advanced ceramics, high-temperature heat treatment of metals, glass manufacturing, and semiconductor processing where temperatures routinely exceed what other electric elements can handle, typically operating between 1200°C and 1800°C (2192°F to 3272°F).

The choice to use MoSi2 heating elements is driven by one primary factor: the need for reliable, stable, and long-lasting heat in oxidizing atmospheres at temperatures above 1600°C. Their unique ability to form a self-healing protective layer makes them unparalleled for the most demanding high-temperature processes.

The Defining Characteristic: Extreme Temperature Capability

The value of MoSi2 elements is rooted in their material science. Unlike other elements that simply degrade faster at high temperatures, MoSi2 leverages the heat to protect itself.

How MoSi2 Achieves High Temperatures

At temperatures above approximately 1000°C, MoSi2 elements react with oxygen in the furnace atmosphere. This reaction forms a thin, non-porous passivation layer of silica (SiO2) on the element's surface.

This self-healing silica layer acts as a protective barrier, preventing further oxidation of the underlying material and allowing the element to function durably at extreme temperatures.

The Impact on Furnace Performance

This unique property results in exceptionally stable resistance over the element's long life. Because the elements do not age or change their electrical characteristics, new elements can be connected in series with older ones without issue.

Furthermore, MoSi2 elements can handle high watt loads and fast thermal cycling, enabling rapid furnace heat-up and cool-down times without causing thermal shock or degradation.

Core Industrial Applications

The high-temperature stability of MoSi2 makes it essential for a range of specialized industrial and scientific processes.

Sintering and Firing of Ceramics

Processes like sintering zirconia and firing alumina require uniform, stable temperatures that often exceed 1600°C. MoSi2 elements provide the necessary heat and control to ensure consistent material properties.

Metal Heat Treatment

While many metal treatments occur at lower temperatures, specialized processes like high-temperature annealing and hardening require the capabilities of MoSi2 elements to achieve the desired metallurgical structures.

Glass and Semiconductor Manufacturing

The manufacturing and processing of specialty glass and certain semiconductor materials involve melting or diffusion steps that occur at very high temperatures. MoSi2 provides a clean, electric heat source suitable for these sensitive environments.

Research and Laboratory Furnaces

In research settings, the ability to achieve precise, repeatable, and extreme temperatures is critical for materials development. MoSi2 elements are a standard component in high-temperature lab furnaces used for a wide array of experiments.

Understanding the Trade-offs and Limitations

While powerful, MoSi2 elements are not a universal solution. Their performance is highly dependent on specific operating conditions, and ignoring these can lead to premature failure.

The "MoSi2 Pest": A Critical Low-Temperature Vulnerability

MoSi2 elements are susceptible to a destructive phenomenon known as the "Pest" or pesting. This occurs when the material is held for extended periods in a temperature range of approximately 400°C to 700°C.

In this range, rapid oxidation occurs along the grain boundaries before a protective silica layer can form, causing the element to disintegrate into a powder. Furnaces using MoSi2 must therefore be programmed to pass through this temperature range quickly during heat-up and cool-down.

Dependence on Oxidizing Atmospheres

The protective silica layer requires oxygen to form. Using MoSi2 elements in low-oxygen, reducing, or vacuum atmospheres significantly lowers their maximum operating temperature and lifespan, as the self-healing mechanism is disabled.

MoSi2 vs. Silicon Carbide (SiC)

Compared to Silicon Carbide (SiC), another common high-temperature element, MoSi2 offers a higher maximum temperature (1800°C+ vs. ~1600°C for SiC). MoSi2 resistance is stable with age, while SiC resistance increases over time, requiring replacement in matched sets.

However, SiC elements are not susceptible to the "Pest" phenomenon and can be more robust in applications with frequent cycling through lower temperature ranges.

Making the Right Choice for Your Goal

Selecting the correct heating element requires understanding the complete thermal profile and atmosphere of your process, not just the peak temperature.

- If your primary focus is operating consistently above 1600°C in an oxidizing atmosphere: MoSi2 is the definitive and most durable choice.

- If your process involves prolonged holds in the 400-700°C range: MoSi2 should be avoided due to the high risk of "Pest" disintegration; consider SiC or other alternatives.

- If your highest temperature is below 1550°C and you prioritize operational simplicity: Silicon Carbide (SiC) is often a more practical and cost-effective solution.

Ultimately, choosing the right heating element is about matching the material's unique strengths and weaknesses to the specific demands of your thermal application.

Summary Table:

| Application | Key Benefits | Temperature Range |

|---|---|---|

| Sintering Ceramics | Uniform heating, stable temperatures | 1200°C - 1800°C |

| Metal Heat Treatment | High-temp annealing, hardening | Up to 1800°C |

| Glass Manufacturing | Clean electric heat source | Above 1600°C |

| Semiconductor Processing | Precise temperature control | 1200°C - 1800°C |

| Research Laboratories | Repeatable extreme temperatures | 1200°C - 1800°C |

Upgrade your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable MoSi2 heating elements and custom furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise performance for your unique experimental needs, delivering durability and efficiency in oxidizing atmospheres up to 1800°C. Contact us today to discuss how we can enhance your thermal applications!

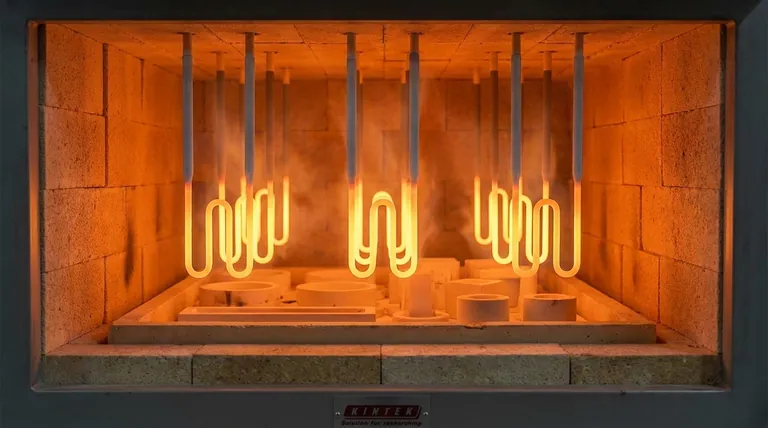

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How can high temperature heating elements be customized for different applications? Tailor Elements for Peak Performance

- What role do MoSi2 heating elements play in 1500 °C experiments? Key to Stability and Precision

- What are the advantages of using molybdenum-disilicide heating elements for aluminum alloy processing? (Rapid Heating Guide)

- What are the key differences between SiC and MoSi2 heating elements in sintering furnaces? Choose the Right Element for Your High-Temp Needs

- What types of molybdenum disilicide heating elements are available? Choose the Right Element for Your High-Temp Needs