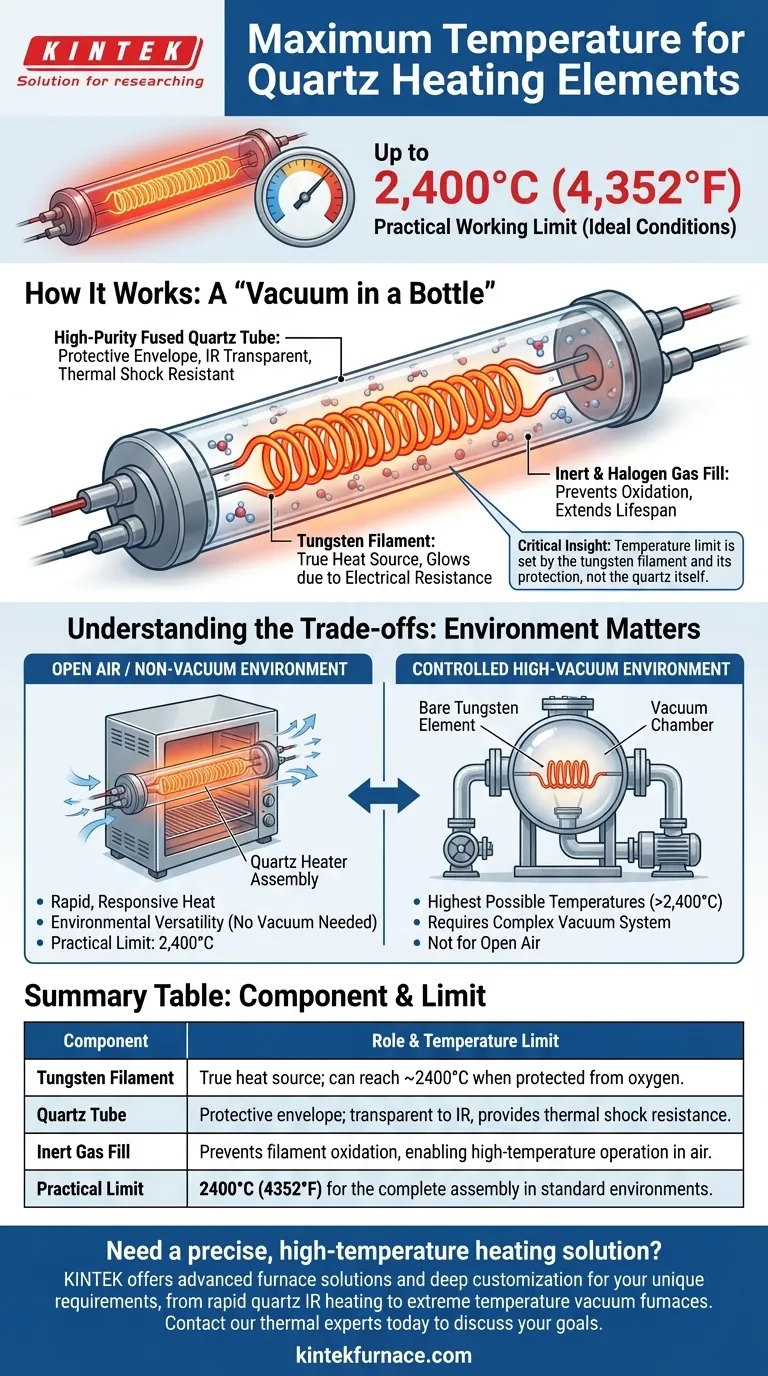

Under ideal conditions, a quartz infrared heating element can reach a working temperature of up to 2,400°C (4,352°F). This temperature, however, applies to the complete heating assembly and depends heavily on the internal components and the operating environment.

The critical insight is that "quartz heater" temperature is not limited by the quartz itself, but by the tungsten filament inside and its protection from oxygen. The quartz tube acts as a protective, transparent envelope, enabling high temperatures in open air that would otherwise require a vacuum.

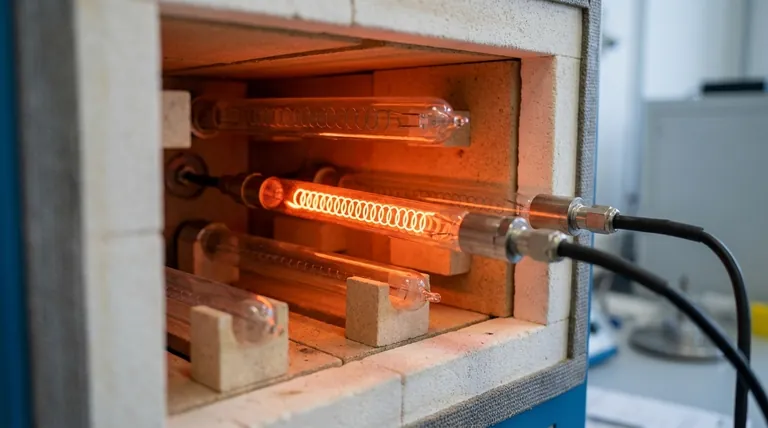

How Quartz Heaters Actually Work

To understand the temperature limits, you must first understand that the quartz is not the source of heat. It is a critical component that enables the true heat source to function effectively.

The Quartz Tube is an Envelope

The "quartz" in a quartz heater refers to a tube made of high-purity fused quartz. This material is chosen because it is highly transparent to infrared radiation and has excellent thermal shock resistance, meaning it can handle rapid temperature changes without cracking.

The Real Heat Source: A Tungsten Filament

Inside the quartz tube is a coiled filament, typically made of tungsten or a tungsten alloy. When electrical current passes through this filament, its resistance causes it to glow intensely hot, emitting powerful short-wave infrared energy.

The Role of Inert Gas

The quartz tube is sealed and filled with an inert gas, often with a small amount of a halogen gas like bromine or iodine. This prevents the hot tungsten filament from oxidizing (burning out) when exposed to air and allows it to operate at much higher temperatures for a longer lifespan.

Why the Operating Environment is Critical

The maximum temperature of any heating element is dictated by its material properties and its interaction with the surrounding environment. The quartz heater assembly is a clever solution to this fundamental problem.

The Problem of Oxidation

Most metals, including tungsten, oxidize rapidly at extreme temperatures. A bare tungsten filament operating in open air would burn out almost instantly. This is why the highest temperatures for tungsten are achieved only in a vacuum, where there is no oxygen.

Quartz Heaters: A "Vacuum in a Bottle"

A quartz lamp effectively creates a self-contained, protected environment for the filament. This allows it to reach incredibly high temperatures while the heater itself operates in normal atmospheric conditions or where air movement is present.

The 2,400°C Practical Limit

The stated maximum of 2,400°C is the practical working limit for the entire quartz heater assembly. This accounts for the filament temperature, the thermal limits of the quartz tube, and the integrity of the seals where the electrical connections are made.

Understanding the Trade-offs

Choosing a heating technology is always about balancing performance, cost, and environmental requirements.

Advantage: Rapid, Responsive Heat

Quartz heaters provide near-instantaneous heat. Because they primarily emit short-wave infrared energy, they are excellent for processes that require rapid heating and cooling cycles. They transfer energy directly to the target material with high efficiency.

Advantage: Environmental Versatility

The primary advantage of a quartz heater is its ability to deliver extremely high temperatures without needing a complex vacuum chamber. This makes it ideal for industrial ovens, drying processes, and semiconductor manufacturing where open-air heating is necessary.

Limitation: Absolute Temperature Ceiling

While 2,400°C is extremely hot, it is not the absolute limit for heating. If a process requires temperatures approaching the melting point of tungsten (3,400°C), a quartz heater is insufficient. Such applications demand a specialized system using a bare tungsten element inside a carefully controlled vacuum environment.

Making the Right Choice for Your Goal

Your application's specific requirements will determine whether a quartz heater is the correct solution.

- If your primary focus is rapid, high-intensity heating in an open-air or non-vacuum environment: A quartz infrared heater is the definitive choice, providing temperatures up to 2,400°C.

- If your primary focus is reaching the highest possible temperatures (above 2,400°C): You must use a system with a bare tungsten element operating within a controlled high-vacuum or pure inert gas atmosphere.

Ultimately, understanding the function of each component empowers you to select the right tool for your specific thermal processing challenge.

Summary Table:

| Component | Role & Temperature Limit |

|---|---|

| Tungsten Filament | The true heat source; can reach ~2400°C when protected from oxygen. |

| Quartz Tube | Protective envelope; transparent to IR, provides thermal shock resistance. |

| Inert Gas Fill | Prevents filament oxidation, enabling high-temperature operation in air. |

| Practical Limit | 2400°C (4352°F) for the complete assembly in standard environments. |

Need a precise, high-temperature heating solution for your lab or process?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Whether your application requires the rapid heating of a quartz IR element or the extreme temperatures of a vacuum furnace, our product line—including Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization capabilities to meet your unique experimental requirements.

Contact our thermal experts today to discuss how we can design the ideal heating system for your goals.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C