In selecting heating elements for a sintering furnace, the choice between Molybdenum Disilicide (MoSi2) and Silicon Carbide (SiC) is a critical decision that directly impacts process capability, operational cost, and furnace uptime. The right choice depends on a careful evaluation of your specific operating temperature, furnace atmosphere, required heating speed, and maintenance protocols. MoSi2 is the standard for very high-temperature applications (above 1550°C) in oxidizing atmospheres, while SiC is a versatile workhorse valued for its rapid thermal response and flexibility across different atmospheres below that temperature.

The decision between MoSi2 and SiC is not about which is "better" overall, but which is optimal for a specific task. MoSi2 provides unmatched high-temperature performance in air, whereas SiC offers superior operational flexibility, speed, and robustness in more varied and lower-temperature environments.

The Core Difference: How They Work

Understanding the fundamental material science of each element is key to appreciating their respective strengths and weaknesses.

Molybdenum Disilicide (MoSi2): The High-Temperature Specialist

MoSi2 elements operate based on the formation of a protective outer layer. When heated in an oxidizing atmosphere, the element forms a thin, self-healing layer of pure silica (glass).

This silica layer is what allows MoSi2 to function at extreme temperatures up to 1800°C. It acts as a barrier, preventing further oxidation and degradation of the core element.

Silicon Carbide (SiC): The Versatile Workhorse

SiC elements are robust, monolithic ceramic components that resist heat through their inherent material properties. They do not rely on forming a protective layer in the same way MoSi2 does.

This straightforward nature makes them physically durable and capable of operating in a wider range of furnace atmospheres, including both oxidizing and reducing conditions.

Key Decision Factor 1: Operating Temperature

The single most important factor in your decision is the maximum required sintering temperature for your process.

The SiC Temperature Ceiling (~1540°C)

SiC elements have a maximum surface temperature of approximately 1600°C. This translates to a practical maximum furnace operating temperature of around 1530°C to 1540°C.

For any sintering process that consistently runs below this threshold, SiC is a viable and often preferred option.

The MoSi2 Advantage (Above 1550°C)

MoSi2 is the definitive choice for processes requiring temperatures above 1550°C. With element temperatures reaching 1800°C or higher, they enable furnace operations in the 1600°C to 1700°C range and beyond.

If your material requires these higher sintering temperatures, the decision is effectively made for you; MoSi2 is the only practical option.

Key Decision Factor 2: Furnace Atmosphere

The chemical environment inside your furnace will have a significant impact on element performance and longevity.

MoSi2's Reliance on Oxygen

The protective silica layer that gives MoSi2 its high-temperature capability requires oxygen to form and self-heal. For this reason, MoSi2 excels in oxidizing atmospheres like air.

In reducing atmospheres, this protective layer cannot be maintained, making the element vulnerable to degradation.

SiC's Atmospheric Flexibility

SiC elements are significantly more versatile. They perform well in oxidizing, inert, and reducing atmospheres, making them an excellent choice for laboratories or production lines that handle a variety of processes.

This flexibility is one of SiC's primary advantages over the more specialized MoSi2.

Understanding the Trade-offs: Maintenance and Lifespan

Beyond temperature and atmosphere, the day-to-day realities of operation and maintenance present a crucial set of trade-offs.

SiC: Aging and Replacement Strategy

SiC elements age over time. Their electrical resistance gradually increases with use, which can affect power delivery and temperature uniformity.

When an SiC element fails, it is best practice to replace elements in matched sets or even complete furnace sets. This is because pairing a new, low-resistance element with old, high-resistance ones can cause an electrical imbalance and premature failure. They are typically wired in parallel.

MoSi2: Sensitivity and Contamination

While MoSi2 elements can have a very long lifespan, they are more sensitive to their operating conditions. They are particularly susceptible to chemical attack from process contaminants.

MoSi2 elements are also prone to a low-temperature degradation phenomenon known as "pesting" (accelerated oxidation) between 400°C and 700°C. This means furnaces must be heated and cooled rapidly through this range. They are wired in series, which can simplify control but means a single break can disable a circuit.

Process Dynamics: Speed vs. Stability

SiC elements are known for their rapid thermal response. They can be heated and cooled quickly, making them ideal for processes that require fast cycling.

MoSi2 elements are valued for their exceptional temperature stability and uniformity at peak temperatures, which is critical for achieving consistent results in sensitive, high-temperature sintering runs.

Making the Right Choice for Your Sintering Process

Use these guidelines to align the element's characteristics with your primary operational goal.

- If your primary focus is maximum temperature (above 1550°C) in an air atmosphere: MoSi2 is the definitive and necessary choice for its unparalleled performance in these conditions.

- If your primary focus is process flexibility, rapid heating cycles, or running varied atmospheres: SiC offers superior versatility, responsiveness, and robustness for multi-purpose use.

- If your primary focus is minimizing hands-on maintenance and having a forgiving system: SiC is generally more robust against operational variance, though its elements require periodic replacement as a set.

- If your primary focus is long-term stability in a dedicated high-temperature process: A well-maintained MoSi2 system, operated with care, will provide exceptional longevity and stability.

Choosing the right element is not about finding the "best" one, but about aligning the element's inherent characteristics with the precise demands of your application.

Summary Table:

| Factor | MoSi2 | SiC |

|---|---|---|

| Max Operating Temperature | Above 1550°C (up to 1800°C) | Up to 1540°C |

| Atmosphere Compatibility | Oxidizing (e.g., air) | Oxidizing, inert, reducing |

| Heating Speed | Slower, stable at high temps | Rapid thermal response |

| Maintenance | Sensitive to contaminants, requires careful handling | Periodic replacement in sets, robust to variance |

| Wiring | Series | Parallel |

Ready to optimize your sintering furnace with the right heating elements? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your lab's efficiency and performance!

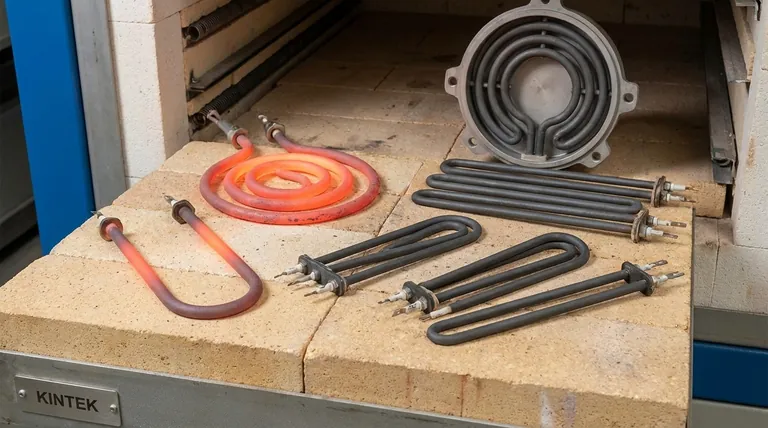

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat