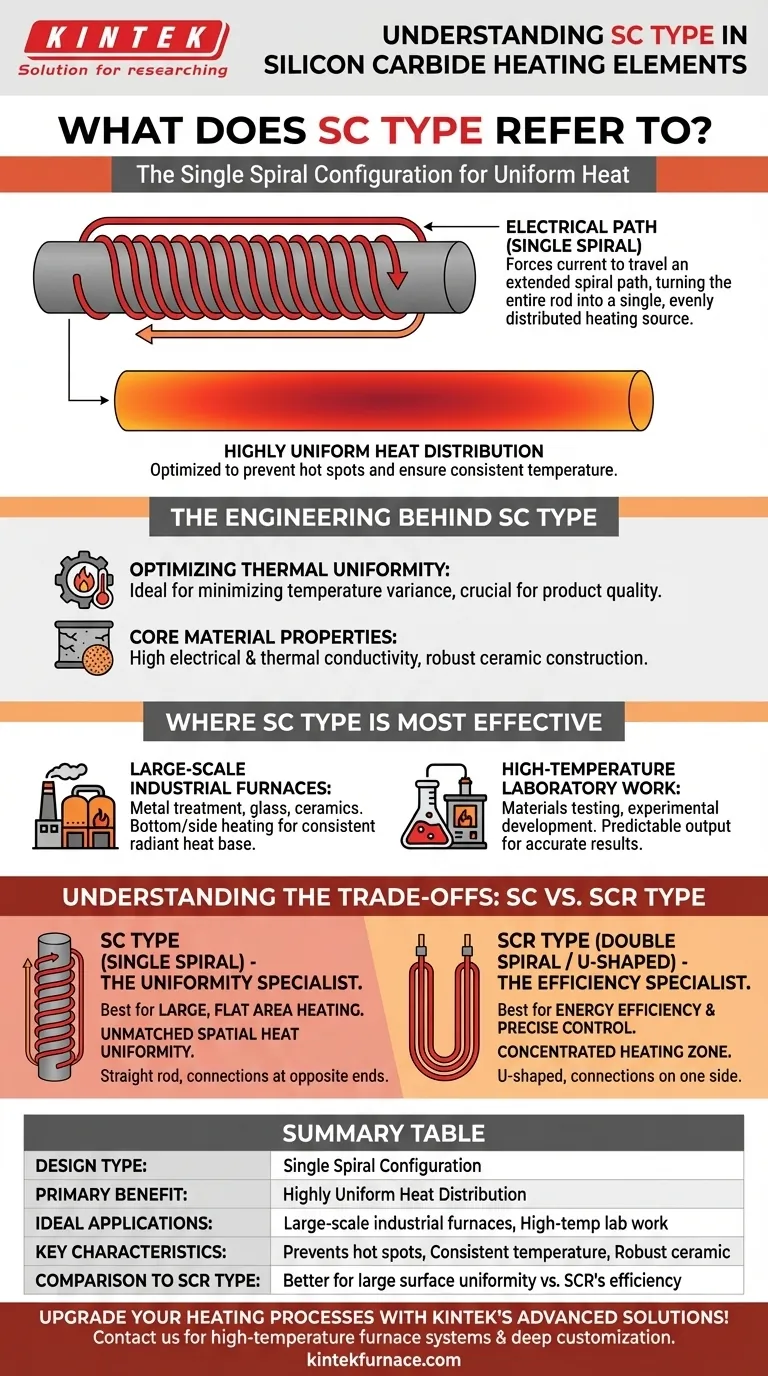

In silicon carbide heating elements, SC Type refers to a specific design known as the Single Spiral configuration. This design features a single, continuous spiral cut into the ceramic rod, creating the electrical path for heating. It is engineered to optimize for highly uniform heat distribution, making it a standard choice for applications where temperature consistency across a surface is critical.

While silicon carbide (SiC) heating elements come in various shapes, the SC Type's Single Spiral design is engineered for one primary purpose: delivering exceptionally uniform heat distribution across a large surface area. This makes it a specialized tool for specific industrial and laboratory heating challenges.

The Engineering Behind the SC Type Design

To understand why the SC Type is chosen, we must look at how its physical design directly influences its performance characteristics.

The Single Spiral Configuration

The "Single Spiral" is a helical groove cut along the length of the SiC rod. This forces the electrical current to travel a long, spiral path from one end of the element to the other.

This extended path is the key to its function. It effectively turns the entire rod into a single, evenly distributed resistive heating source.

Optimizing for Thermal Uniformity

The primary benefit of the single spiral design is the prevention of "hot spots." Because the current path is spread out evenly, the heat generated is exceptionally consistent along the element's entire length.

This makes the SC Type ideal for applications requiring minimal temperature variance, such as the bottom or side heating of large-scale industrial furnaces where spatial temperature uniformity is crucial for product quality.

Core Material Properties

Like other SiC elements, the SC Type is a ceramic material with high electrical conductivity and good thermal conductivity. This allows it to reach high temperatures efficiently while remaining structurally stable.

Its robust construction provides high resistance to electrical currents and ensures effective, reliable heat generation for demanding processes.

Where the SC Type is Most Effective

The unique characteristics of the SC Type make it the preferred choice in specific high-temperature environments.

Large-Scale Industrial Furnaces

The SC Type is a workhorse in industries like metal treatment, glass manufacturing, and ceramics production. It is frequently used in large box furnaces and trolley furnaces.

In these settings, elements are often laid on the furnace floor or mounted along the sides to provide a consistent, radiant heat base that ensures the entire workload is heated evenly.

High-Temperature Laboratory Work

In laboratory settings, process control is paramount. The SC Type provides the reliable and stable heating required for high-temperature research, materials testing, and experimental development.

Its predictable and uniform output helps ensure that experimental results are accurate and repeatable.

Understanding the Trade-offs: SC vs. Other Types

The SC Type is not the only design available. Understanding its counterparts, such as the SCR Type, clarifies its specific advantages.

SC Type (Single Spiral): The Uniformity Specialist

The SC Type's strength is its unmatched spatial heat uniformity. When you need to heat a large, flat area with minimal temperature difference from point to point, the single spiral rod is the superior design.

SCR Type (Double Spiral / U-Shaped): The Efficiency Specialist

The SCR Type is often a U-shaped element, sometimes featuring a double spiral. This design concentrates the heating zone and typically offers enhanced energy efficiency and very precise temperature control.

It is often chosen for technically demanding applications where power consumption is a key concern or where the furnace geometry favors a U-shaped element with terminals on the same side.

Choosing Based on Furnace Geometry

The physical shape is a major differentiator. SC elements are straight rods that require electrical connections at opposite ends. SCR elements are U-shaped, allowing for connections on one side of the furnace, which can simplify wiring and installation in certain furnace designs.

Making the Right Choice for Your Application

Selecting the correct heating element requires matching the element's design intent to your process goals.

- If your primary focus is uniform heating across a large surface (e.g., the floor of a large furnace): The SC Type's Single Spiral design is engineered specifically for this purpose.

- If your primary focus is energy efficiency or you need to fit an element into a space with single-side access: Consider an SCR (U-shaped) Type, which is often optimized for lower power consumption and simplified wiring.

- If your primary focus is general laboratory research requiring stable, reliable heat: The SC Type is a proven and dependable choice for standard high-temperature testing environments.

Understanding the design intent behind each element type empowers you to select the precise tool for your high-temperature objective.

Summary Table:

| Feature | Description |

|---|---|

| Design Type | Single Spiral Configuration |

| Primary Benefit | Highly Uniform Heat Distribution |

| Ideal Applications | Large-scale industrial furnaces, high-temperature lab work |

| Key Characteristics | Prevents hot spots, consistent temperature, robust ceramic material |

| Comparison to SCR Type | Better for large surface uniformity vs. SCR's efficiency and U-shape |

Upgrade your heating processes with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for uniform heating and efficiency. Contact us today to discuss how our SC Type elements and other products can enhance your operations!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan