In short, Molybdenum Disilicide (MoSi2) heating elements are predominantly used in industrial high-temperature furnaces for glass manufacturing, ceramic sintering, metal heat treatment, and semiconductor processing. Their unique ability to operate reliably at extreme temperatures in air makes them essential for processes where conventional heating elements would fail.

The core reason industries choose MoSi2 is for its exceptional performance above 1600°C (2912°F). The element forms a protective silica layer during operation, allowing it to resist oxidation and deliver rapid, clean heat in the most demanding thermal environments.

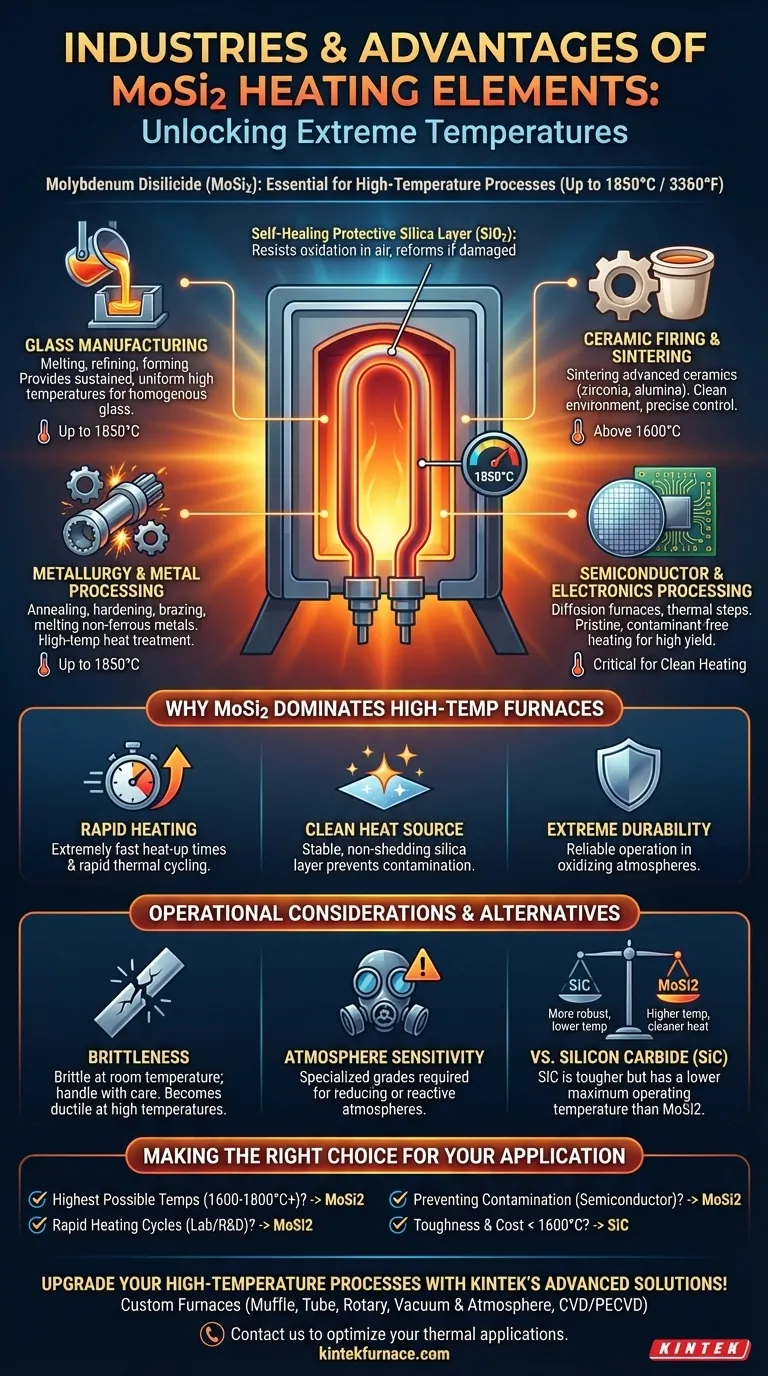

Why MoSi2 Dominates High-Temperature Furnaces

The adoption of MoSi2 elements is driven by a unique combination of material properties that solve critical challenges in high-temperature manufacturing. It isn't just about getting hot; it's about how the element behaves under extreme stress.

Unmatched Performance at Extreme Temperatures

MoSi2 elements are a specialized solution designed for the upper range of industrial heating. They can operate at element temperatures up to 1850°C (3360°F).

This capability is crucial for melting glass, sintering advanced ceramics, and performing specific metallurgical processes that are simply unattainable with more common iron-chromium-aluminum (FeCrAl) or even silicon carbide (SiC) elements.

A "Self-Healing" Protective Layer

The key to MoSi2's longevity in air is its chemistry. When heated, the molybdenum silicide reacts with oxygen to form a thin, non-porous layer of quartz glass (SiO2) on its surface.

This passive layer is what protects the underlying material from further, destructive oxidation. If the layer is cracked or damaged, it instantly reforms, effectively "healing" itself as long as oxygen is present.

Rapid Heating and Thermal Cycling

MoSi2 elements have a low mass and can handle high power loads, allowing for extremely fast furnace heat-up times.

Recent advancements have also produced grades optimized for rapid thermal cycling, a critical requirement in laboratory research furnaces and some high-throughput production environments where furnaces are cooled and reheated frequently.

Key Industrial Applications Breakdown

MoSi2 elements are not a general-purpose solution. They are specified for applications where their high-temperature capabilities justify their cost and specific operating requirements.

Glass Manufacturing

In the glass industry, MoSi2 elements are used in melting, refining, and forming processes. They provide the sustained, uniform high temperatures necessary to create a homogenous glass melt free of impurities.

Ceramic Firing and Sintering

Sintering advanced ceramics like zirconia and alumina requires precise temperature control at levels often exceeding 1600°C. MoSi2 elements provide the clean heating environment necessary to achieve the desired material density and strength without contamination.

Metallurgy and Metal Processing

These elements are used in high-temperature heat treatment furnaces for annealing, hardening, and brazing metals. They are also employed in furnaces for melting non-ferrous metals with high melting points, such as copper, gold, and silver.

Semiconductor and Electronics Processing

The production of semiconductors and electronic components demands pristine, contaminant-free heating. MoSi2 elements are used in diffusion furnaces and other thermal processing steps where stable temperatures and a clean atmosphere are critical to device yield.

Understanding the Operational Trade-offs

While powerful, MoSi2 elements have specific characteristics that must be managed for successful operation. Understanding these limitations is key to their proper application.

Brittleness at Room Temperature

MoSi2 is a cermet (ceramic-metal composite), making it very brittle at low temperatures. The elements must be handled with care during installation and are susceptible to mechanical shock before they reach operating temperature, where they become more ductile.

Atmosphere Sensitivity

The protective silica layer that forms in oxidizing atmospheres (like air) is the element's greatest strength. However, in certain reducing or reactive atmospheres (like nitrogen or hydrogen at specific temperatures), this layer can break down, leading to rapid element failure. Specialized grades are available for these conditions.

The Role of Alternatives like Silicon Carbide (SiC)

Silicon Carbide (SiC) heating elements are another common choice for high-temperature applications, often competing with MoSi2. SiC is generally more robust and resistant to mechanical shock but typically has a lower maximum operating temperature than MoSi2. The choice between them often depends on the peak temperature required and the furnace atmosphere.

Making the Right Choice for Your Application

Selecting the right heating element requires matching the technology to your primary operational goal.

- If your primary focus is reaching the highest possible temperatures (1600-1800°C): MoSi2 is the definitive choice for operating in an air atmosphere.

- If your primary focus is rapid heating cycles in a lab or R&D setting: MoSi2's ability to handle high power density and thermal cycling makes it ideal.

- If your primary focus is preventing product contamination: The stable, non-shedding silica layer on MoSi2 provides an exceptionally clean heat source for sensitive processes like semiconductor manufacturing.

- If your primary focus is toughness and cost-effectiveness below 1600°C: A Silicon Carbide (SiC) element may be a more robust and economical alternative.

Ultimately, choosing MoSi2 is a decision to prioritize unparalleled high-temperature performance where other heating technologies simply cannot operate.

Summary Table:

| Industry | Key Applications | Temperature Range |

|---|---|---|

| Glass Manufacturing | Melting, refining, forming | Up to 1850°C |

| Ceramic Firing | Sintering zirconia, alumina | Above 1600°C |

| Metallurgy | Annealing, hardening, brazing | Up to 1850°C |

| Semiconductor Processing | Diffusion furnaces, thermal steps | Critical for clean heating |

Upgrade your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with MoSi2-equipped furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior performance, rapid heating, and contamination-free environments. Contact us today to discuss how we can optimize your thermal applications!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance