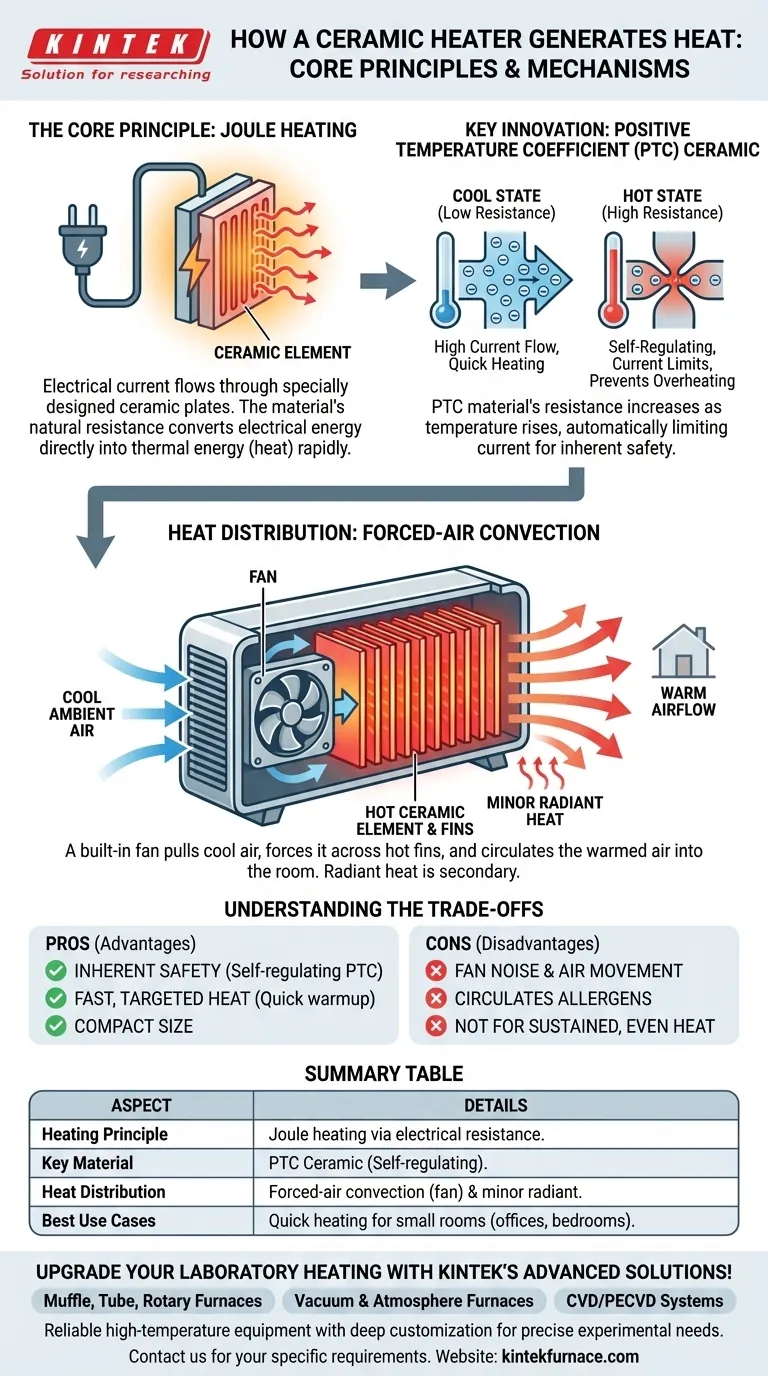

At its core, a ceramic heater generates heat through the principle of electrical resistance. When an electric current is passed through specially designed ceramic plates, the material naturally resists the flow of electricity. This resistance converts the electrical energy directly into thermal energy, a process known as Joule heating, which rapidly warms the ceramic element.

The true innovation of a ceramic heater is not just its ability to generate heat, but its capacity to manage it. The Positive Temperature Coefficient (PTC) ceramic material is self-regulating, meaning it automatically reduces its heat output as it gets warmer, making it inherently safer and more stable than older resistive heating technologies.

The Core Mechanism: From Electricity to Warmth

To understand a ceramic heater, we must look at both the material itself and the way it's used to distribute heat. It's a simple but highly effective system.

The Principle of Resistive Heating

Any material that resists the flow of electricity will generate heat when a current is forced through it. This is the same fundamental principle that makes the coils in a toaster glow red.

However, unlike simple metal coils, ceramic heaters use advanced semiconductor materials that are far more sophisticated.

Why Use Ceramic?

The "ceramic" in these heaters is a complex composite engineered for specific thermal properties. It is an excellent electrical resistor but also a very effective conductor of heat.

This dual nature allows it to heat up almost instantly and then efficiently transfer that heat to the surrounding air.

The Key Feature: PTC Ceramic

Modern ceramic heaters use Positive Temperature Coefficient (PTC) materials. This is the technology's most important safety and efficiency feature.

PTC means the material's electrical resistance increases as its temperature rises. As the ceramic element reaches its designed operating temperature, its higher resistance naturally limits the electric current, preventing it from getting any hotter. This creates a self-regulating system that avoids overheating without complex electronics.

How the Heat Spreads: Forced-Air Convection

Generating heat is only half the battle; distributing it is what makes a space feel warm. Most ceramic heaters are convection heaters.

The Primary Method: A Fan-Driven System

Ceramic heaters almost always include a built-in fan. This fan pulls cool ambient air from the room and forces it across a series of fins connected to the hot ceramic element.

The air rapidly absorbs the heat and is then blown back into the room, creating a current of warm air that circulates and raises the overall room temperature. This is why you feel a directed flow of warm air when you turn one on.

A Minor Role: Radiant Heat

While the primary method is convection, the hot surface of the heater also emits some infrared radiation. This radiant heat warms objects and people directly in its line of sight.

However, for a typical ceramic space heater, this effect is secondary to the powerful fan-driven circulation of warm air.

Understanding the Trade-offs

No heating technology is perfect for every situation. The design of a ceramic heater creates a distinct set of advantages and disadvantages.

Pro: Inherent Safety

The self-regulating nature of PTC ceramic makes these heaters exceptionally safe. They are designed to never reach a temperature that could ignite common household materials. They also typically run cooler to the touch than many radiant metal heaters.

Pro: Fast, Targeted Heat

Because of the fan, ceramic heaters are excellent at providing heat quickly. They are ideal for warming a specific area or a small, enclosed room in a matter of minutes.

Con: Fan Noise and Air Movement

The fan, while effective, is a source of constant low-level noise. It also circulates dust, pollen, and other allergens that may be present in the air, which can be a concern for sensitive individuals.

Con: Not Ideal for Sustained, Even Heat

Convection heat warms the air, not the objects in the room. Once the heater is turned off, the warm air cools quickly, and the feeling of warmth dissipates. This makes them less efficient for maintaining a stable temperature in a large or poorly insulated space compared to a radiant heater.

Making the Right Choice for Your Goal

Selecting a heater depends entirely on your specific heating objective.

- If your primary focus is quickly heating a small office or bedroom: A ceramic heater is an excellent choice due to its fast-acting convection and compact size.

- If your primary focus is silent, sustained heat for a larger living area: An oil-filled radiator, which provides steady radiant heat without a fan, is likely a better option.

- If your primary focus is safety around children or pets: A ceramic heater is one of the safest portable options thanks to its self-regulating PTC element and cooler external surfaces.

Understanding this core mechanism empowers you to choose a heating solution based on its fundamental principles, not just marketing claims.

Summary Table:

| Aspect | Details |

|---|---|

| Heating Principle | Joule heating through electrical resistance in ceramic elements |

| Key Material | Positive Temperature Coefficient (PTC) ceramic for self-regulation |

| Heat Distribution | Primarily forced-air convection with a fan; minor radiant heat |

| Main Advantages | Inherent safety, fast targeted heating, self-regulating temperature |

| Main Disadvantages | Fan noise, air movement circulates allergens, not ideal for sustained heat in large spaces |

| Best Use Cases | Quick heating for small rooms (e.g., offices, bedrooms), safe for children and pets |

Upgrade Your Laboratory Heating with KINTEK's Advanced Solutions!

Are you looking for reliable, high-performance heating equipment for your lab? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental needs. Whether you're in materials science, chemistry, or any field requiring precise thermal management, our products ensure safety, efficiency, and durability.

Don't settle for less—enhance your research with KINTEK's innovative technology. Contact us today to discuss how we can support your specific requirements and drive your projects forward!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability