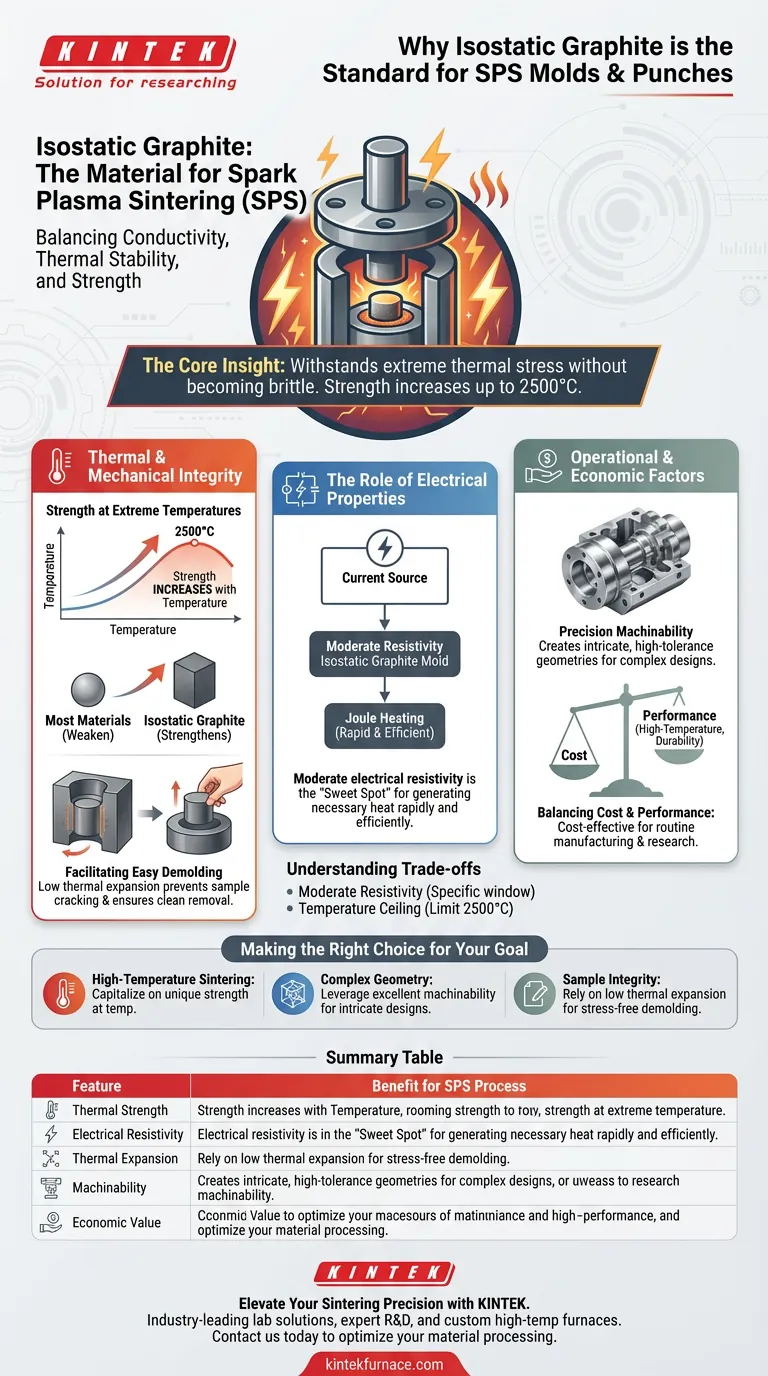

Isostatic graphite is the standard material for Spark Plasma Sintering (SPS) because it provides the necessary balance between electrical conductivity, thermal stability, and mechanical strength. Its moderate electrical resistivity enables efficient Joule heating, while its unique ability to strengthen at high temperatures ensures structural integrity during the sintering process.

The Core Insight Isostatic graphite solves the central contradiction of high-temperature sintering: it withstands extreme thermal stress without becoming brittle. Unlike most materials that weaken under heat, it becomes mechanically stronger up to 2500°C while facilitating the precise electrical heating required for SPS.

Thermal and Mechanical Integrity

Strength at Extreme Temperatures

In most engineering materials, rising temperatures lead to structural weakness and potential failure. Isostatic graphite behaves differently; its mechanical strength actually increases as the temperature rises, up to approximately 2500°C.

Critical Stability for High-Heat Applications

This unique property makes it exceptionally reliable for SPS, where rapid heating rates are standard. The material maintains its shape and pressure-bearing capacity exactly when the sintering conditions are most demanding.

Facilitating Easy Demolding

Dimensional stability is crucial when retrieving a sintered sample. Isostatic graphite possesses a low thermal expansion coefficient.

Preventing Sample Damage

Because the mold does not expand or contract aggressively during thermal cycling, the risk of the mold seizing or cracking the sintered sample is significantly reduced. This ensures the final product can be removed cleanly after the process.

The Role of Electrical Properties

Enabling Efficient Joule Heating

SPS relies on passing a large electrical current through the mold to generate heat (Joule heating). The mold material must be conductive, but not too conductive.

The "Moderate" Sweet Spot

Isostatic graphite offers moderate electrical resistivity. This provides enough resistance to generate the necessary heat rapidly when current is applied, while still allowing the current to flow through the assembly efficiently.

Operational and Economic Factors

Precision Machinability

SPS often requires complex mold shapes and punch geometries to create specific component designs. Isostatic graphite is known for its excellent machinability, allowing for the creation of intricate, high-tolerance tools.

Balancing Cost and Performance

Tooling is a consumable resource in sintering processes. Isostatic graphite is cost-effective relative to its high-performance capabilities, making it the optimal economic choice for routine manufacturing and research.

Understanding the Trade-offs

The Limits of "Moderate" Resistivity

While moderate resistivity is ideal for general Joule heating, it is a specific operational window. If your process requires highly specialized electrical flow characteristics outside of this "moderate" range, standard isostatic graphite may require process adjustments.

Temperature Ceilings

While the material strengthens up to 2500°C, this is a physical limit. Processes requiring sustained temperatures beyond this threshold may push the material beyond its reliable performance envelope based on standard specifications.

Making the Right Choice for Your Goal

To maximize the success of your SPS runs, align your tooling strategy with the specific advantages of isostatic graphite.

- If your primary focus is High-Temperature Sintering: Capitalize on the material's unique property of increasing strength up to 2500°C to apply consistent pressure without fear of tool collapse.

- If your primary focus is Complex Component Geometry: Leverage the material's excellent machinability to design intricate punch and mold shapes without incurring prohibitive fabrication costs.

- If your primary focus is Sample Integrity: Rely on the low thermal expansion coefficient to minimize stress on the sample during the cooling and demolding phases.

Isostatic graphite remains the industry standard because it successfully unifies the competing demands of thermal durability, electrical efficiency, and economic viability.

Summary Table:

| Feature | Benefit for SPS Process |

|---|---|

| Thermal Strength | Mechanical strength increases up to 2500°C, ensuring structural integrity. |

| Electrical Resistivity | Moderate resistivity enables efficient Joule heating for rapid sintering. |

| Thermal Expansion | Low expansion coefficient prevents sample cracking and ensures easy demolding. |

| Machinability | Allows for intricate, high-tolerance mold and punch geometries at low cost. |

| Economic Value | Provides a cost-effective balance between performance and tool longevity. |

Elevate Your Sintering Precision with KINTEK

Isostatic graphite is essential for successful Spark Plasma Sintering, but the right equipment makes the difference. KINTEK provides industry-leading lab solutions backed by expert R&D and manufacturing. We offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable high-temperature furnaces designed to meet your unique sintering requirements.

Ready to optimize your material processing? Contact us today to discuss your specific needs and discover how our advanced heating solutions can enhance your laboratory's efficiency.

Visual Guide

References

- Alexander M. Laptev, Olivier Guillon. Tooling in Spark Plasma Sintering Technology: Design, Optimization, and Application. DOI: 10.1002/adem.202301391

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What function does a vacuum hot press furnace serve in the densification of Nb-22.5Cr-5Si alloys? Achieve Full Density and Purity for Refractory Alloys

- What role does a sealed quartz glass tube play in hot press sintering? Achieve Oxide-Free Aluminum Composites

- How does hot pressing differ from ordinary cold pressing and sintering? Unlock Superior Material Performance

- What core functions do graphite molds serve? Essential Roles in Vacuum Hot Pressing Sintering of SiC/ZTA Ceramics

- What are the technical advantages of using a HIP furnace for MgB2 wires? Unlock Peak Superconducting Density

- How are hot press furnaces involved in semiconductor manufacturing? Essential for Wafer Bonding in 3D ICs

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- What are the technical advantages of Spark Plasma Sintering (SPS) systems? Faster Densification and Superior Strength