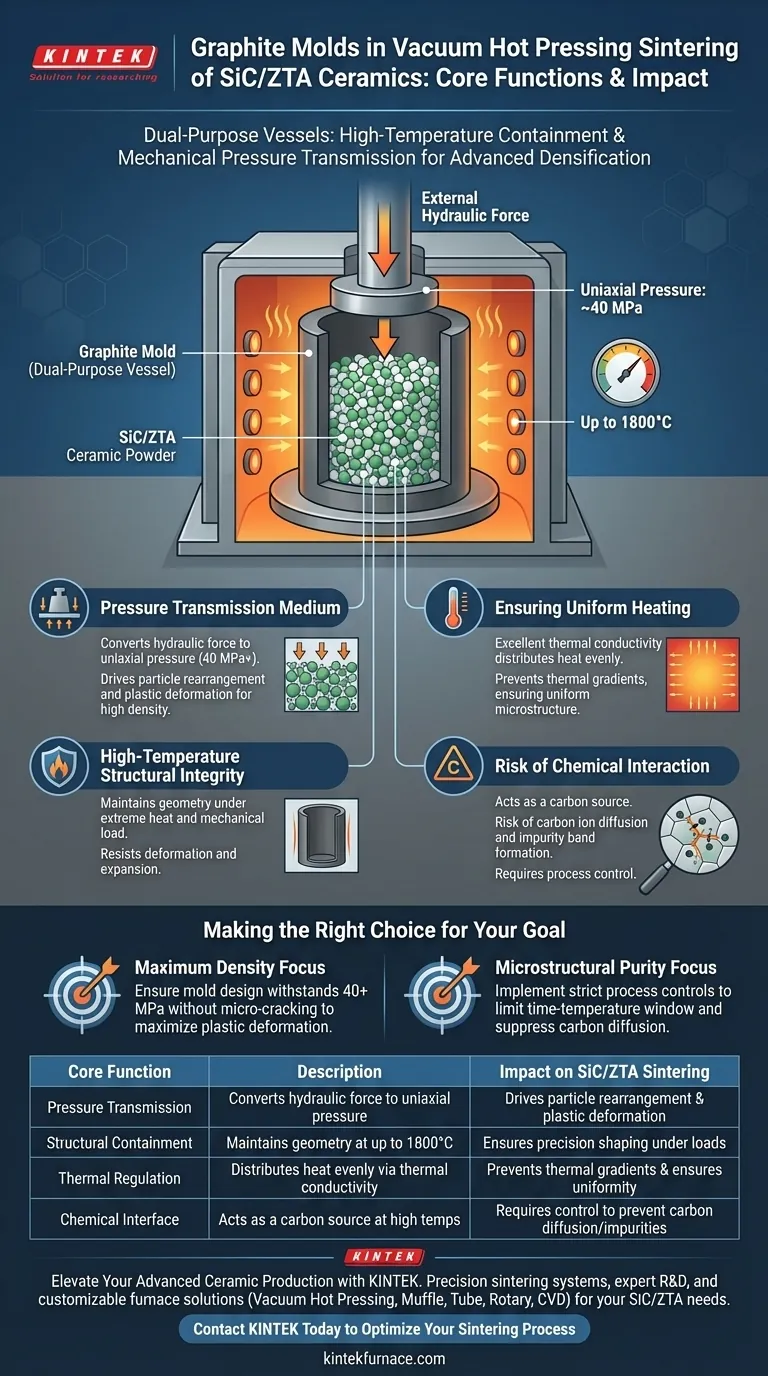

Graphite molds function primarily as dual-purpose vessels that act as both high-temperature resistant containers and mechanical pressure transmitters. During the vacuum hot pressing of SiC/ZTA ceramics, they facilitate densification by effectively converting external hydraulic force into the internal uniaxial pressure required to fuse hard-to-sinter powders.

Core Takeaway: Beyond simply holding the shape, the graphite mold serves as an active process component. It enables the simultaneous application of extreme heat and mechanical force—essential for triggering the particle rearrangement and plastic deformation necessary to achieve full density in advanced ceramics.

The Mechanics of Densification

Acting as a Pressure Transmission Medium

The most critical role of the graphite mold is to serve as a pressure transmission medium. It acts as the physical interface between the external hydraulic system and the ceramic powder.

By withstanding significant uniaxial pressures (typically around 40 MPa), the mold forces the internal powder to undergo particle rearrangement. This pressure is the catalyst for plastic deformation, allowing the material to achieve high density even before reaching its theoretical melting point.

High-Temperature Structural Integrity

To sinter materials like SiC (Silicon Carbide) and ZTA (Zirconia Toughened Alumina), the environment must reach extreme temperatures, often up to 1800°C.

The graphite mold operates as a robust container that maintains the specific geometry of the component under these conditions. It must possess high hot-strength to resist expanding or deforming under the combined load of thermal stress and mechanical pressure.

Thermal Regulation Roles

Ensuring Uniform Heating

Graphite is selected for this process due to its excellent thermal conductivity.

As heat is applied, the mold distributes thermal energy evenly across the surface of the ceramic sample. This prevents thermal gradients—hot spots or cold spots—that could lead to uneven microstructures or internal stresses in the final sintered product.

Understanding the Trade-offs

The Risk of Chemical Interaction

While graphite is mechanically ideal, it introduces a chemical variable: it acts as a carbon source.

At elevated temperatures, there is a risk that carbon ions may diffuse from the mold into the ceramic material. This can lead to the formation of impurity bands along the grain boundaries of the ceramic. Process control must account for this diffusion to prevent the degradation of the ceramic's electrical or optical properties.

Making the Right Choice for Your Goal

To optimize your sintering process, consider how the mold functions relative to your specific targets:

- If your primary focus is Maximum Density: Ensure your mold design and grade can withstand uniaxial pressures exceeding 40 MPa without micro-cracking, to maximize plastic deformation.

- If your primary focus is Microstructural Purity: Implement strict process controls to manage grain growth and limit the time-temperature window, suppressing the diffusion of carbon ions into the ceramic matrix.

The graphite mold is not merely a consumable tool; it is a critical process variable that dictates the structural integrity and uniformity of your final ceramic component.

Summary Table:

| Core Function | Description | Impact on SiC/ZTA Sintering |

|---|---|---|

| Pressure Transmission | Converts hydraulic force to uniaxial pressure (40 MPa+) | Drives particle rearrangement and plastic deformation |

| Structural Containment | Maintains component geometry at temperatures up to 1800°C | Ensures precision shaping under high thermal and mechanical loads |

| Thermal Regulation | Distributes heat evenly via high thermal conductivity | Prevents thermal gradients and ensures uniform microstructure |

| Chemical Interface | Acts as a carbon source at high temperatures | Requires process control to prevent carbon ion diffusion and impurities |

Elevate Your Advanced Ceramic Production with KINTEK

Precision sintering requires more than just high temperatures; it demands the right equipment to manage pressure and thermal uniformity. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Vacuum Hot Pressing systems, Muffle, Tube, Rotary, and CVD furnaces—all fully customizable to your unique SiC/ZTA processing needs.

Whether you are aiming for maximum material density or superior microstructural purity, our technical team is ready to provide the specialized lab solutions your research deserves.

Contact KINTEK Today to Optimize Your Sintering Process

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

People Also Ask

- Why is a high-vacuum environment required during SPS for transparent materials? Achieve Optical Purity

- How do graphite molds function during the SPS of Ti-6Al-4Zr-4Nb alloys? Mastering Dual-Action Sintering

- Why is an argon atmosphere required during SPS of Ti-6Al-4Zr-4Nb alloys? Protect Your High-Performance Titanium

- What are the benefits of a heat press machine? Achieve Professional, Durable Results

- Why is a laboratory vacuum system essential for the SPS of LaFeO3? Ensure Phase Purity and Tooling Longevity

- Why is a Vacuum Hot Pressing Sintering Furnace Essential for 6061-20IQC? Unlock High-Performance Composites

- What role do hot press furnaces play in powder metallurgy? Achieve High-Density Components Efficiently

- What are the key benefits of using a vacuum press for sintering metal and ceramic powders? Achieve Superior Density and Purity