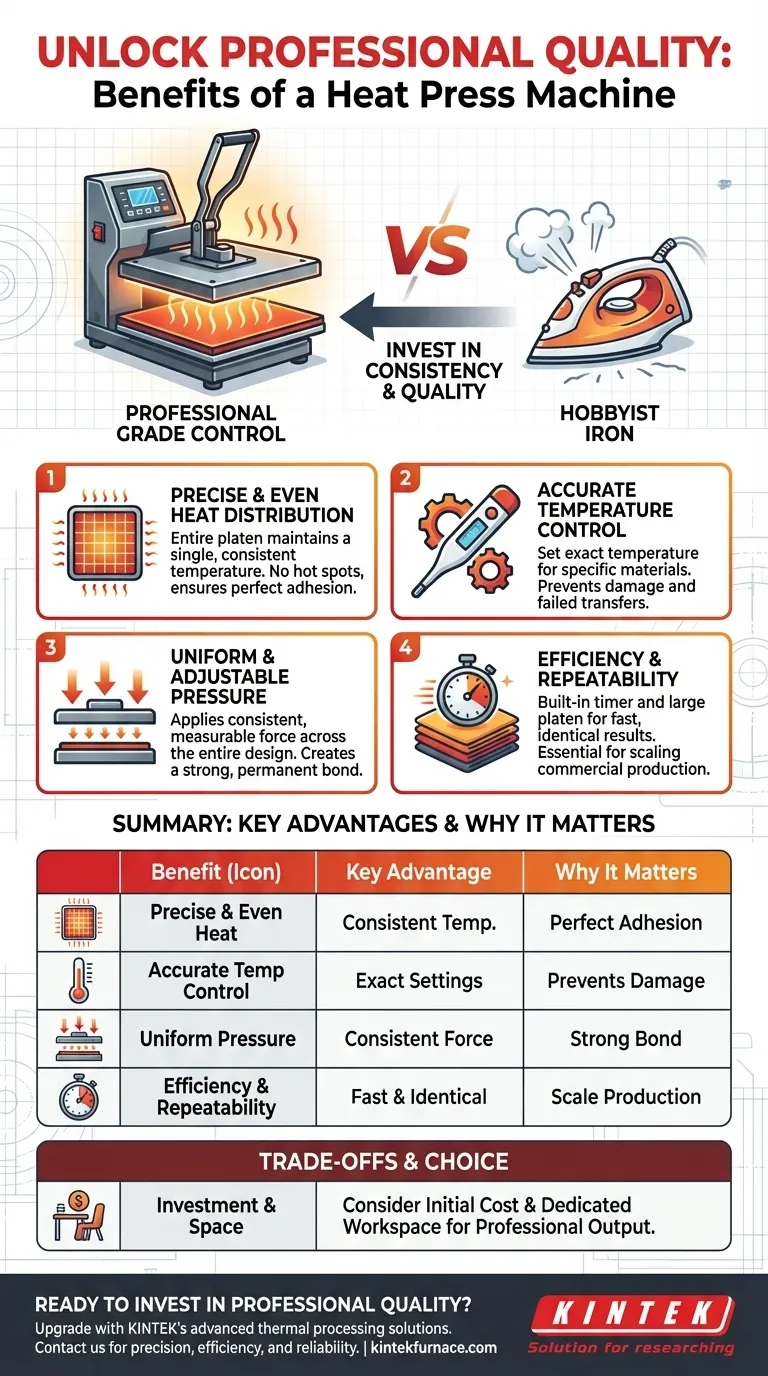

At its core, a heat press offers professional-grade control that a household iron simply cannot match. Its primary benefits are the ability to deliver precise and consistent temperature, apply uniform pressure, and do so efficiently over time. This control is the fundamental difference between a hobbyist craft and a durable, commercial-quality product.

While a simple iron can apply a design, a heat press is an investment in repeatability and quality. Its ability to deliver exact, even, and consistent heat and pressure is the critical factor that creates a professional, durable, and sellable final product.

Why a Heat Press Delivers Professional Results

To understand the benefits of a heat press, you must first understand the core principles of heat transfer. A successful application depends on a perfect balance of three elements: heat, pressure, and time. A heat press is engineered to master all three.

Benefit 1: Precise and Even Heat Distribution

A heat press is designed with a solid, thick platen containing internal heating elements. This ensures the entire surface maintains a single, consistent temperature.

There are no "hot spots" or cool edges. This is critical because transfer materials, like heat transfer vinyl (HTV) or sublimation inks, have specific activation temperatures. Even heat guarantees the entire design adheres or infuses correctly.

Benefit 2: Accurate Temperature Control

Different materials require different temperatures. Sublimation on polyester requires a high heat (around 400°F), while certain types of vinyl will scorch at that temperature.

A heat press allows you to set the exact temperature required for your specific material, down to the degree. This precision prevents damaged garments and failed transfers, which are common issues when using an iron with vague settings like "Cotton" or "Linen."

Benefit 3: Uniform and Adjustable Pressure

Pressure is arguably the most overlooked element by beginners. It is the force that bonds the transfer adhesive to the fabric's fibers or, in sublimation, pushes the ink gas into the material.

A heat press applies consistent, measurable pressure across the entire design simultaneously. You cannot replicate this with an iron, where you rely on inconsistent body weight and arm strength, leading to peeling corners and uneven adhesion.

Benefit 4: Efficiency and Repeatability

For anyone making more than a single item, efficiency is key. A heat press with a built-in timer and a large platen allows you to produce identical items quickly.

Once you dial in the settings for a specific type of shirt and vinyl, you can produce dozens of identical products with the same high-quality result. This level of repeatability is impossible with an iron.

Understanding the Trade-offs

While superior for professional work, a heat press is a specialized tool with considerations that a simple iron does not have.

The Initial Investment

The most significant factor is cost. A quality heat press is a financial investment compared to a household iron. It is a machine built for durability and precision, and its price reflects that.

Space Requirements

Heat presses are heavier and larger than irons. They require a stable, dedicated workspace that can handle their weight and heat output. They are not as easily stored or moved.

The Learning Curve

While not excessively steep, there is a learning curve. You must learn the correct temperature, pressure, and time settings for different materials (e.g., cotton vs. polyester, standard HTV vs. glitter). This initial testing phase is essential for achieving perfect results.

Making the Right Choice for Your Goal

Your decision should be based entirely on the quality and scale you want to achieve.

- If your primary focus is a one-off personal project: An iron might suffice, but be prepared for potential imperfections and lower durability over time.

- If your primary focus is starting a craft business or creating sellable goods: A heat press is a non-negotiable tool for ensuring professional quality and customer satisfaction.

- If your primary focus is consistency and efficiency: The heat press is the only tool that can deliver repeatable, high-quality results at any scale.

Ultimately, choosing a heat press is a commitment to quality and control in your work.

Summary Table:

| Benefit | Key Advantage | Why It Matters |

|---|---|---|

| Precise & Even Heat | Entire platen maintains a single, consistent temperature. | Eliminates hot/cold spots for perfect, full-design adhesion. |

| Accurate Temperature Control | Set exact temperatures for specific materials. | Prevents scorching or failed transfers, ensuring material integrity. |

| Uniform & Adjustable Pressure | Applies consistent, measurable pressure across the entire design. | Creates a strong, permanent bond that prevents peeling. |

| Efficiency & Repeatability | Built-in timer and large platen for fast, identical results. | Essential for producing sellable, commercial-quality goods at scale. |

Ready to Invest in Professional Quality?

Upgrade from hobbyist crafts to durable, commercial-grade products with a heat press machine from KINTEK. Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories and businesses with advanced thermal processing solutions. Our product line, including Muffle, Tube, and Rotary Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique production requirements.

Contact us today to discuss how our solutions can bring precision, efficiency, and reliability to your workflow.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

People Also Ask

- What is a vacuum press and what are its primary uses? Unlock High-Performance Material Processing

- How does hot pressing work? Achieve Maximum Density and Strength for Advanced Materials

- How does tailored heat and pressure control benefit hot pressing? Achieve Superior Material Density and Strength

- What are the typical operational steps when using a vacuum press? Master Flawless Bonding and Forming

- What are the applications of hot pressing? Achieve Maximum Material Performance