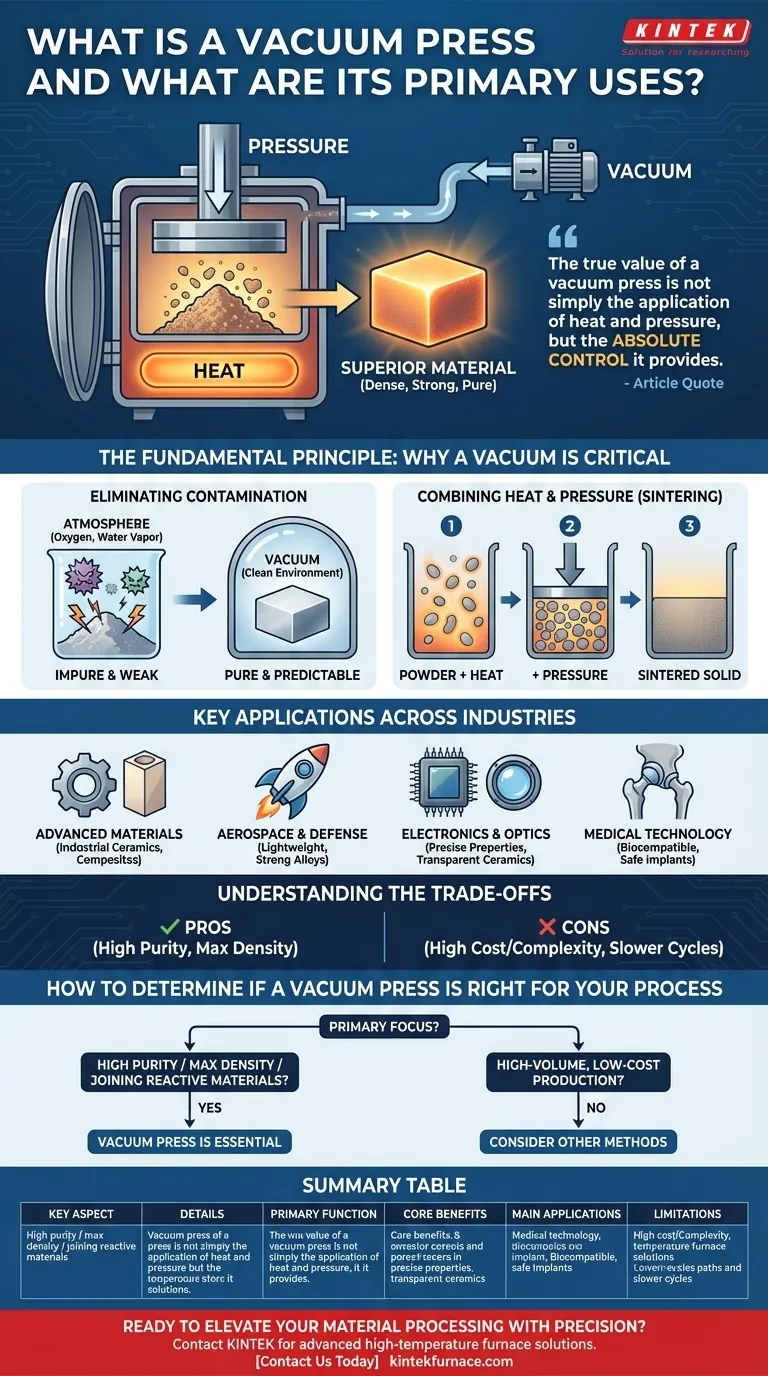

At its core, a vacuum press is a specialized furnace that combines high temperature and high pressure within a vacuum-sealed chamber. Its purpose is to process materials in a contamination-free environment, allowing for the creation of advanced materials with superior properties like enhanced density, strength, and purity.

The true value of a vacuum press is not simply the application of heat and pressure, but the absolute control it provides. By removing reactive gases like oxygen, it enables the forging and bonding of materials that would be impossible to create in the open air.

The Fundamental Principle: Why a Vacuum is Critical

A vacuum press, often called a vacuum hot press, solves a fundamental problem in materials science. Many advanced materials are highly reactive at the temperatures needed to shape or bond them.

Eliminating Atmospheric Contamination

At high temperatures, materials can readily react with gases in the atmosphere, especially oxygen and water vapor. This reaction, known as oxidation, can create impurities, compromise structural integrity, and alter the material's intended properties.

A vacuum press removes the atmosphere from the chamber, creating a clean environment. This prevents unwanted chemical reactions, ensuring the final product is pure and predictable.

Combining Heat and Pressure for Densification

The process relies on two key forces working in concert.

- Heat makes the atoms within a material (like a metal or ceramic powder) more mobile.

- Pressure then physically forces these mobile particles together, closing up pores and voids.

This combined action, known as sintering, bonds the particles into a solid, dense mass. The vacuum ensures this bonding happens without trapping gas bubbles inside, leading to near-perfect densification.

Key Applications Across Industries

The ability to create pure, dense, and strong materials makes the vacuum press indispensable in high-performance sectors.

Advanced Materials Manufacturing

This is the primary domain of the vacuum press. It's used to create materials like industrial ceramics, refractory metals, and carbon composites. By sintering powders, it produces solid components that are exceptionally hard, wear-resistant, and can withstand extreme temperatures.

Aerospace and Defense

The aerospace industry requires components that are both lightweight and incredibly strong. Vacuum presses are used to create high-strength alloys and composite materials for engine parts, structural components, and armor that meet these demanding specifications.

Electronics and Optics

For electronic components, precise thermal and electrical properties are non-negotiable. Vacuum pressing helps create specialized substrates and materials with controlled conductivity. It is also used to sinter transparent ceramics for optical applications like high-power laser windows and lenses.

Medical Technology

Biocompatibility is paramount for medical implants. A vacuum press is used to fabricate materials for implants and surgical tools that are pure, dense, and non-reactive with the human body, ensuring safety and longevity.

Understanding the Trade-offs

While powerful, a vacuum press is a specialized tool with specific limitations.

High Initial Cost and Complexity

This is not standard workshop equipment. Vacuum hot presses are a significant capital investment and require skilled operators to manage the precise interplay of vacuum levels, temperature profiles, and pressure cycles.

Slower Process Cycles

Achieving a deep vacuum, heating the material, applying pressure, and cooling down is an inherently slow process. This makes it less suitable for high-volume manufacturing where speed is the primary driver.

It Is Not a Universal Solution

For materials that are not sensitive to atmospheric contamination or processes where maximum density isn't the goal, a vacuum press is often unnecessary. Conventional atmospheric furnaces or cold pressing methods can be far more cost-effective.

How to Determine if a Vacuum Press is Right for Your Process

Use these guidelines to decide if the technology aligns with your objective.

- If your primary focus is creating high-purity materials: The vacuum press is essential to prevent oxidation and ensure the final material's chemical integrity.

- If your primary focus is achieving maximum material density: The combination of pressure and vacuum is critical for eliminating porosity in powders and achieving a near-perfectly solid structure.

- If your primary focus is joining reactive or dissimilar materials: Processes like diffusion bonding and vacuum brazing rely on this technology to create strong, clean joints without weak, brittle phases.

- If your primary focus is high-volume, low-cost production: A vacuum press is likely not the most efficient tool; consider atmospheric furnaces or conventional pressing methods first.

Ultimately, a vacuum press is a tool of precision, enabling the creation of next-generation materials by providing absolute control over the processing environment.

Summary Table:

| Key Aspect | Details |

|---|---|

| Primary Function | Combines high temperature and pressure in a vacuum to process materials without contamination. |

| Core Benefits | Achieves high purity, superior density, and enhanced strength in materials. |

| Main Applications | Aerospace (lightweight alloys), electronics (substrates), medical (implants), and advanced ceramics. |

| Limitations | High cost, slow process cycles, and not suitable for high-volume production. |

Ready to elevate your material processing with precision? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're developing aerospace components, medical implants, or electronic materials, we can help you achieve superior purity and density. Contact us today to discuss how our vacuum press solutions can transform your R&D and production processes!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%