At its core, hot pressing is a manufacturing process that simultaneously applies high temperature and significant mechanical pressure to a material. This combined action forces powdered or particulate materials to consolidate, bond together, and form a solid, highly dense final component inside a shaping die.

While conventional sintering uses only heat to slowly bond particles, hot pressing adds external pressure as an active force. This dramatically accelerates the process and allows materials to reach a level of density and strength that is often unachievable with heat alone.

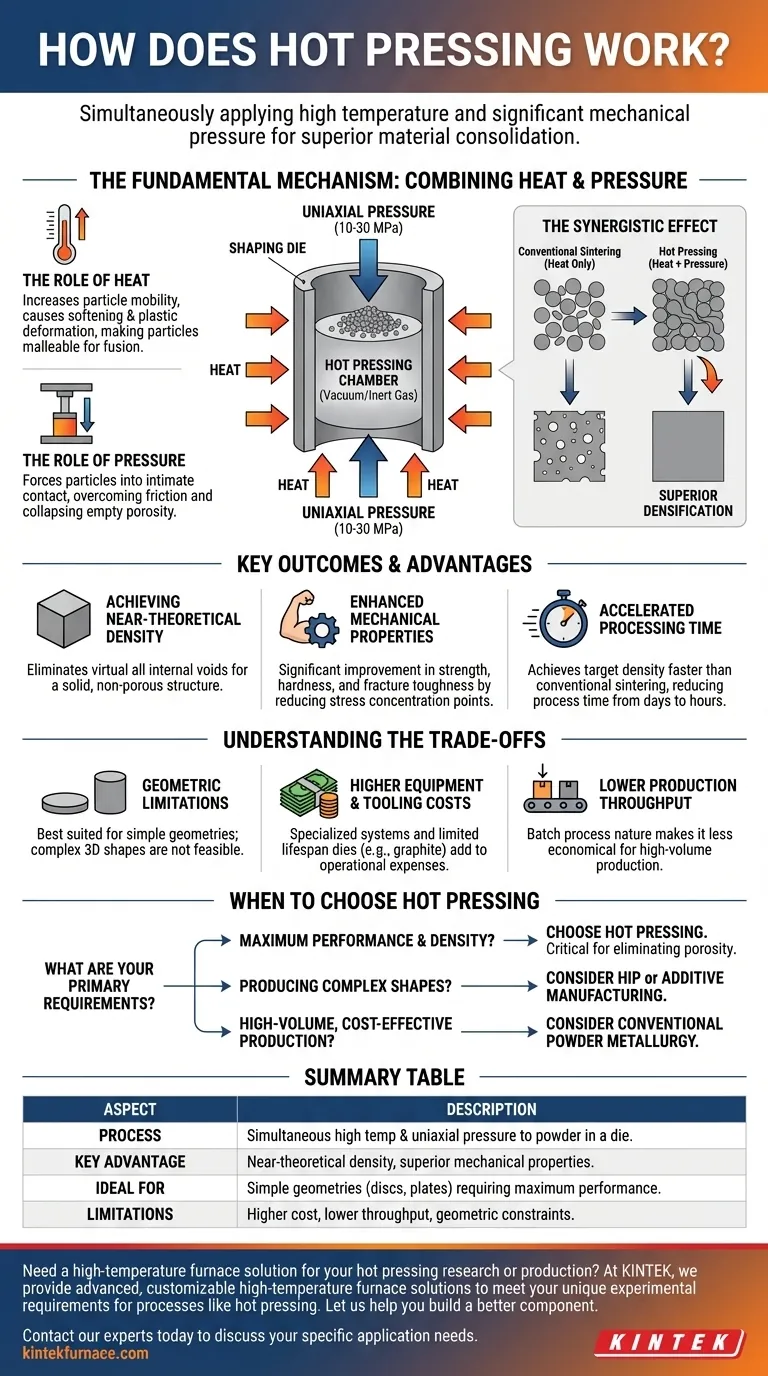

The Fundamental Mechanism: Combining Heat and Pressure

Hot pressing works by creating the ideal conditions for particles to fuse together. This is not just a simple compaction process; it is a synergistic interaction between thermal energy and mechanical force.

The Role of Heat

Heat is the primary enabler of bonding. As the material temperature rises, its atoms become more mobile, and the material itself begins to soften, a phenomenon known as plastic deformation. This makes the individual particles more "malleable" and ready to fuse with their neighbors.

The Role of Pressure

While heat prepares the particles, uniaxial pressure (force applied along a single axis) is the driver of consolidation. This applied force, typically ranging from 10 to 30 MPa, physically pushes the particles into intimate contact, overcoming friction and collapsing the empty spaces, or porosity, between them.

The Synergistic Effect

Neither heat nor pressure is as effective alone. Applying pressure at room temperature would only compact the powder without creating strong atomic bonds. Applying heat alone (conventional sintering) relies on slower, less efficient diffusion mechanisms to close pores. By combining them, hot pressing rapidly forces softened particles together, achieving superior densification.

Key Outcomes and Advantages

The unique combination of heat and pressure gives hot-pressed materials distinct advantages, making it the process of choice for high-performance applications.

Achieving Near-Theoretical Density

The primary benefit of hot pressing is its ability to produce parts with near-theoretical density. This means eliminating virtually all internal voids, resulting in a solid, non-porous structure that is critical for advanced ceramics, composites, and alloys.

Enhanced Mechanical Properties

A direct result of high density is a significant improvement in mechanical strength, hardness, and fracture toughness. With fewer pores acting as stress concentration points and potential failure sites, the material can withstand much higher loads.

Accelerated Processing Time

By actively forcing densification, hot pressing can achieve a target density much faster than conventional sintering. This can reduce processing times from many hours or even days to just a few hours. The process is often conducted in a vacuum or an inert gas atmosphere to prevent oxidation at high temperatures.

Understanding the Trade-offs

While powerful, hot pressing is not a universal solution. It involves specific limitations and costs that must be considered.

Geometric Limitations

Because the pressure is applied uniaxially through a simple die, hot pressing is best suited for producing components with simple geometries, such as discs, plates, and cylinders. Complex, three-dimensional shapes are not feasible with this method.

Higher Equipment and Tooling Costs

Hot press systems are specialized and expensive. The dies, often made of graphite, have a limited lifespan, especially at the extreme temperatures required for many advanced materials, adding to the operational cost.

Lower Production Throughput

Hot pressing is inherently a batch process. Each component or small batch must be individually loaded, processed, and unloaded. This makes it less economical for high-volume production compared to continuous methods like conventional powder metallurgy.

When to Choose Hot Pressing

Your decision to use hot pressing should be driven by the specific performance requirements of your final component.

- If your primary focus is maximum performance and density: Hot pressing is the superior choice for creating components where eliminating porosity is critical for mechanical, optical, or electrical properties.

- If your primary focus is producing complex shapes: Consider alternative methods like Hot Isostatic Pressing (HIP) or advanced additive manufacturing, as hot pressing is limited to simple geometries.

- If your primary focus is high-volume, cost-effective production: Conventional press-and-sinter powder metallurgy is a more economical solution for applications where some residual porosity is acceptable.

Understanding this interplay of heat and pressure allows you to leverage hot pressing for materials that demand the highest levels of density and performance.

Summary Table:

| Aspect | Description |

|---|---|

| Process | Simultaneous application of high temperature and uniaxial pressure to powder in a die. |

| Key Advantage | Produces parts with near-theoretical density and superior mechanical properties. |

| Ideal For | Simple geometries (discs, plates) requiring maximum performance. |

| Limitations | Higher cost, lower throughput, geometric constraints compared to sintering. |

Need a high-temperature furnace solution for your hot pressing research or production?

At KINTEK, we understand that achieving superior material density and performance starts with precise and reliable equipment. Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions.

Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements for processes like hot pressing.

Let us help you build a better component. Contact our experts today to discuss your specific application needs.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What is a vacuum hot press furnace? Unlock Superior Material Performance