In powder metallurgy, a hot press furnace serves a specialized and critical role: to simultaneously apply high temperature and mechanical pressure to a metal powder. This single-step process, known as hot pressing, consolidates the powder directly into a dense, solid component with superior structural integrity and minimal internal porosity.

The core advantage of hot pressing is not just consolidation, but its ability to achieve exceptionally high density and fine-grained microstructures at lower temperatures and pressures than required by separate pressing and sintering steps. This makes it the ideal choice for producing high-performance components from materials that are difficult to densify by other means.

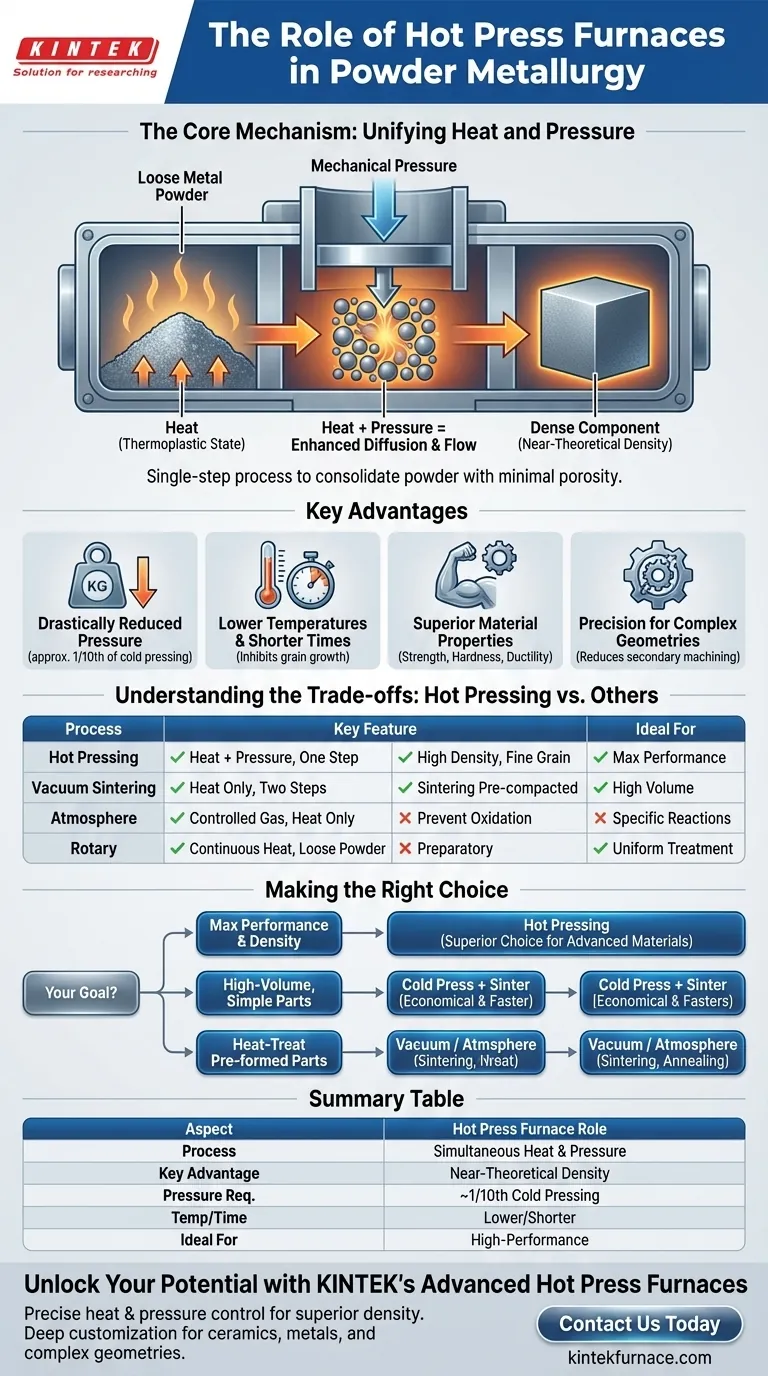

The Core Mechanism: Unifying Heat and Pressure

Hot pressing is fundamentally a thermo-mechanical process that combines the steps of compaction and sintering into a single operation inside the furnace.

How Hot Pressing Works

First, the metal powder is heated to a temperature where it becomes thermoplastic and more malleable. While at this elevated temperature, uniaxial pressure is applied by a press, compacting the softened particles together.

This combination of heat and pressure dramatically enhances material flow and diffusion between particles, closing the voids between them far more effectively than pressure or heat alone.

The Goal: Achieving Near-Theoretical Density

The primary objective of hot pressing is to produce components with a density approaching 100% of the theoretical maximum for that material.

By eliminating porosity, the process yields a fine-grained structure, which is directly responsible for the material's enhanced mechanical and electrical properties.

Key Advantages of the Hot Pressing Process

Choosing a hot press furnace provides distinct advantages over conventional multi-step powder metallurgy routes.

Drastically Reduced Pressure Requirements

Because the powder is in a softened, thermoplastic state, the pressure needed for consolidation is significantly lower. It often requires only about 1/10th of the pressure needed for cold pressing a part to its initial "green" state.

Lower Temperatures and Shorter Sintering Times

The applied pressure accelerates the atomic diffusion and mass transfer needed for sintering. This allows the process to run at lower temperatures and for shorter durations, which is crucial for inhibiting undesirable grain growth and preserving a fine microstructure.

Superior Material Properties

The resulting high density and fine grain structure lead directly to excellent mechanical strength, hardness, and ductility. For certain materials, this also translates to improved electrical conductivity and thermal performance.

Precision for Complex Geometries

Hot pressing allows for the production of parts with complex shapes and accurate final dimensions, often reducing the need for extensive secondary machining operations.

Understanding the Trade-offs: Hot Pressing vs. Other Furnaces

Hot pressing is a powerful tool, but it is not the only thermal process in powder metallurgy. Understanding its place relative to other furnace types is key.

vs. Standard Vacuum Sintering Furnaces

A vacuum furnace is typically used for sintering, a process that applies only heat (under vacuum) to a pre-compacted part (a "green part"). Hot pressing combines compaction and sintering. A vacuum furnace is used when the part has already been shaped by a separate cold pressing step.

vs. Atmosphere Furnaces

Atmosphere furnaces are designed for precise control over the gaseous environment (e.g., nitrogen, argon, hydrogen) to prevent oxidation or induce specific chemical reactions during heat treatment. Like vacuum furnaces, they do not apply mechanical pressure and are used to sinter or anneal pre-formed components.

vs. Rotary Furnaces

Rotary furnaces are primarily used for continuous, uniform heat treatment of loose powders or granules. In powder metallurgy, their role is often preparatory—for drying, calcining, or producing high-quality, consistent powders before they are consolidated in a press or furnace.

Making the Right Choice for Your Goal

Selecting the correct thermal process depends entirely on your material, part complexity, and final performance requirements.

- If your primary focus is maximum performance and density: Hot pressing is the superior choice for creating components with near-perfect density and the finest possible grain structure, especially for advanced ceramics or hard-to-sinter metals.

- If your primary focus is high-volume production of simpler parts: A conventional two-step process of cold pressing followed by sintering in a vacuum or atmosphere furnace is often more economical and faster.

- If your primary focus is heat-treating pre-formed parts: A vacuum or atmosphere furnace is the correct tool for processes like sintering, annealing, or brazing where no further consolidation pressure is needed.

Ultimately, choosing the right furnace is about aligning the process capabilities with your desired material properties and manufacturing objectives.

Summary Table:

| Aspect | Hot Press Furnace Role |

|---|---|

| Process | Simultaneously applies heat and pressure to consolidate metal powders |

| Key Advantage | Achieves near-theoretical density with fine-grained microstructures |

| Pressure Requirement | About 1/10th of cold pressing pressure |

| Temperature/Time | Lower temperatures and shorter sintering times |

| Ideal For | High-performance components from hard-to-densify materials |

Unlock the Full Potential of Your Powder Metallurgy with KINTEK's Advanced Hot Press Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our hot press furnaces are designed to deliver precise heat and pressure control, ensuring superior density and material properties for your unique experimental needs. Whether you're working with ceramics, metals, or complex geometries, our strong deep customization capability tailors solutions to meet your specific requirements.

Contact us today via our contact form to discuss how our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, can enhance your research and production efficiency. Let's achieve your goals together!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%