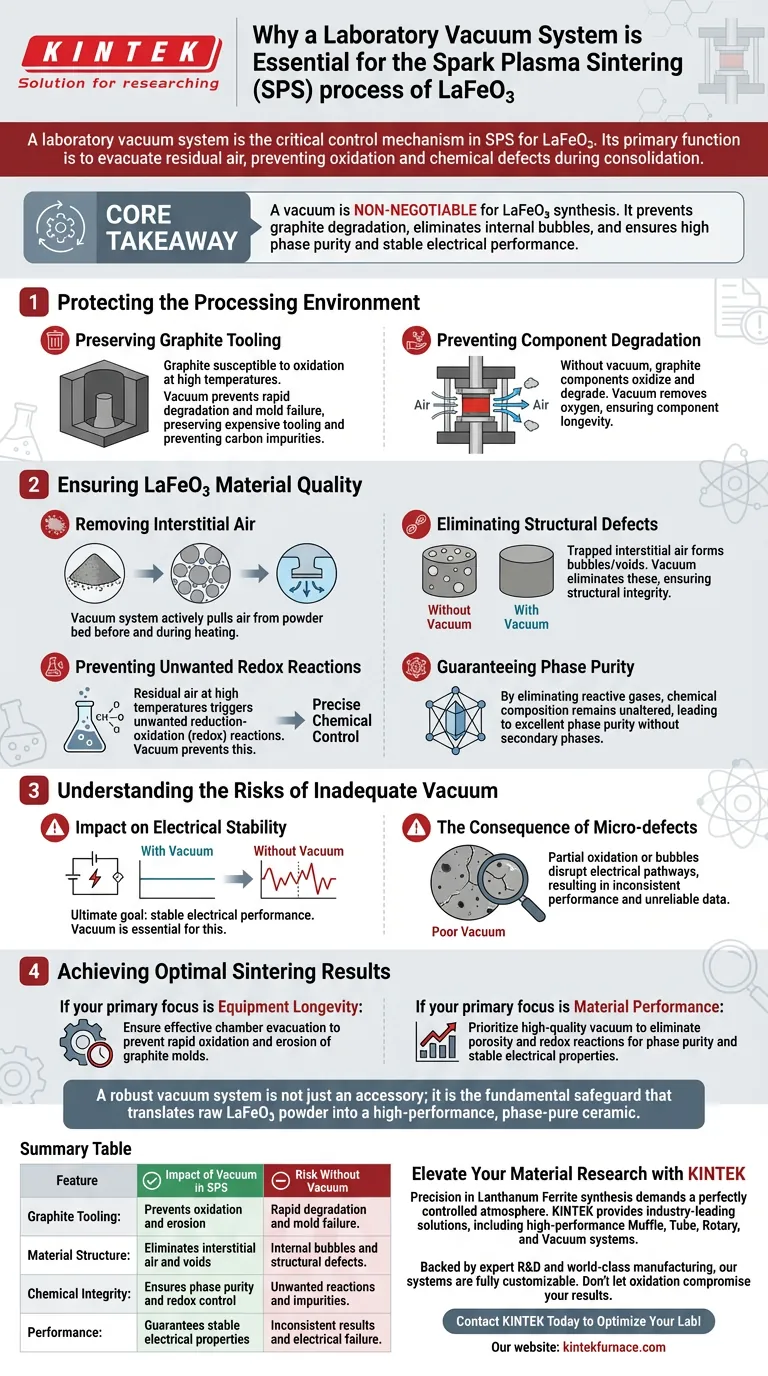

A laboratory vacuum system is the critical control mechanism in the Spark Plasma Sintering (SPS) process for Lanthanum Ferrite (LaFeO3). Its primary function is to evacuate residual air from both the graphite tooling and the interstitial spaces between powder particles, preventing oxidation and chemical defects during the high-temperature consolidation process.

Core Takeaway Attempting SPS without a vacuum environment exposes both the tooling and the sample to trapped oxygen. A vacuum system is non-negotiable for LaFeO3 synthesis because it prevents graphite degradation and eliminates the risk of internal bubbles, ensuring the final ceramic achieves high phase purity and stable electrical performance.

Protecting the Processing Environment

Preserving Graphite Tooling

The SPS process relies heavily on graphite molds to conduct current and apply pressure. However, graphite is highly susceptible to oxidation at the high temperatures required for sintering.

Preventing Component Degradation

Without a vacuum to remove oxygen, the graphite components would oxidize and degrade rapidly. This not only destroys expensive tooling but can also introduce carbon impurities into the processing chamber.

Ensuring LaFeO3 Material Quality

Removing Interstitial Air

LaFeO3 powder particles have microscopic gaps between them filled with air. The vacuum system actively pulls this air out of the powder bed before and during the heating stages.

Eliminating Structural Defects

If this interstitial air is not removed, it becomes trapped as the material densifies. This results in the formation of bubbles or voids within the ceramic, compromising its structural integrity.

Preventing Unwanted Redox Reactions

LaFeO3 synthesis requires precise chemical control. The presence of residual air at high temperatures can trigger unwanted reduction-oxidation (redox) reactions.

Guaranteeing Phase Purity

By eliminating reactive gases, the vacuum ensures that the chemical composition of the LaFeO3 remains unaltered. This leads to excellent phase purity, meaning the material forms the correct crystal structure without secondary, unwanted phases.

Understanding the Risks of Inadequate Vacuum

Impact on Electrical Stability

The ultimate goal of sintering LaFeO3 is often for its electrical applications. The reference highlights that a vacuum is essential for stable electrical performance.

The Consequence of Micro-defects

Even partial oxidation or microscopic bubbles caused by a poor vacuum can disrupt the electrical pathways in the ceramic. This results in inconsistent performance and unreliable data.

Achieving Optimal Sintering Results

If your primary focus is Equipment Longevity:

- Ensure the vacuum system effectively evacuates the chamber to prevent rapid oxidation and erosion of your graphite molds.

If your primary focus is Material Performance:

- Prioritize a high-quality vacuum to eliminate porosity and redox reactions, which is the only way to guarantee the phase purity required for stable electrical properties.

A robust vacuum system is not just an accessory; it is the fundamental safeguard that translates raw LaFeO3 powder into a high-performance, phase-pure ceramic.

Summary Table:

| Feature | Impact of Vacuum in SPS | Risk Without Vacuum |

|---|---|---|

| Graphite Tooling | Prevents oxidation and erosion | Rapid degradation and mold failure |

| Material Structure | Eliminates interstitial air and voids | Internal bubbles and structural defects |

| Chemical Integrity | Ensures phase purity and redox control | Unwanted reactions and impurities |

| Performance | Guarantees stable electrical properties | Inconsistent results and electrical failure |

Elevate Your Material Research with KINTEK

Precision in Lanthanum Ferrite synthesis requires more than just high temperatures; it demands a perfectly controlled atmosphere. KINTEK provides industry-leading laboratory solutions, including high-performance Muffle, Tube, Rotary, and Vacuum systems designed specifically for sensitive sintering processes like SPS.

Backed by expert R&D and world-class manufacturing, our systems are fully customizable to meet your unique research needs, ensuring the phase purity and electrical stability your projects demand. Don't let oxidation compromise your results.

Contact KINTEK Today to Optimize Your Lab!

Visual Guide

References

- Pavel Ctibor, Libor Straka. Characterization of LaFeO3 Dielectric Ceramics Produced by Spark Plasma Sintering. DOI: 10.3390/ma17020287

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Vacuum Hot Pressing Sintering vs. Ultrasonic-Assisted Casting for CNT/Al Composites: Choosing the Right Method

- What is the core function of a vacuum hot pressing furnace? Expert Guide to TiAl/Ti6Al4V Composite Success

- How does the heating mechanism of a vacuum hot pressing sintering furnace differ from SPS? A Comparative Guide

- What core role does a vacuum hot press furnace play in Fe-Cu-Ni-Sn-VN? Mastering Nanostructured Composite Production

- Why is a vacuum environment important in hot pressing? Essential for Purity and High-Density Materials

- What is the purpose of applying vibration to the loaded graphite mold? Enhance TiAl-SiC Composite Sintering Performance

- What is the basic principle of how a vacuum press works? Harness Atmospheric Pressure for Uniform Clamping

- How does vacuum molding contribute to cost-efficiency in metalworking? Reduce Waste and Labor Costs