At its core, vacuum molding drives cost-efficiency in metalworking by creating exceptionally precise molds that require less raw material and significantly reduce the need for post-casting labor. This method minimizes material waste and nearly eliminates secondary machining or trimming, which directly lowers the total cost per part.

The true value of vacuum molding lies in its ability to streamline the entire production process. By producing a near-net-shape casting with a superior surface finish, it cuts hidden costs associated with material scrap, binder consumables, and labor-intensive secondary operations.

The Principle of Vacuum Molding

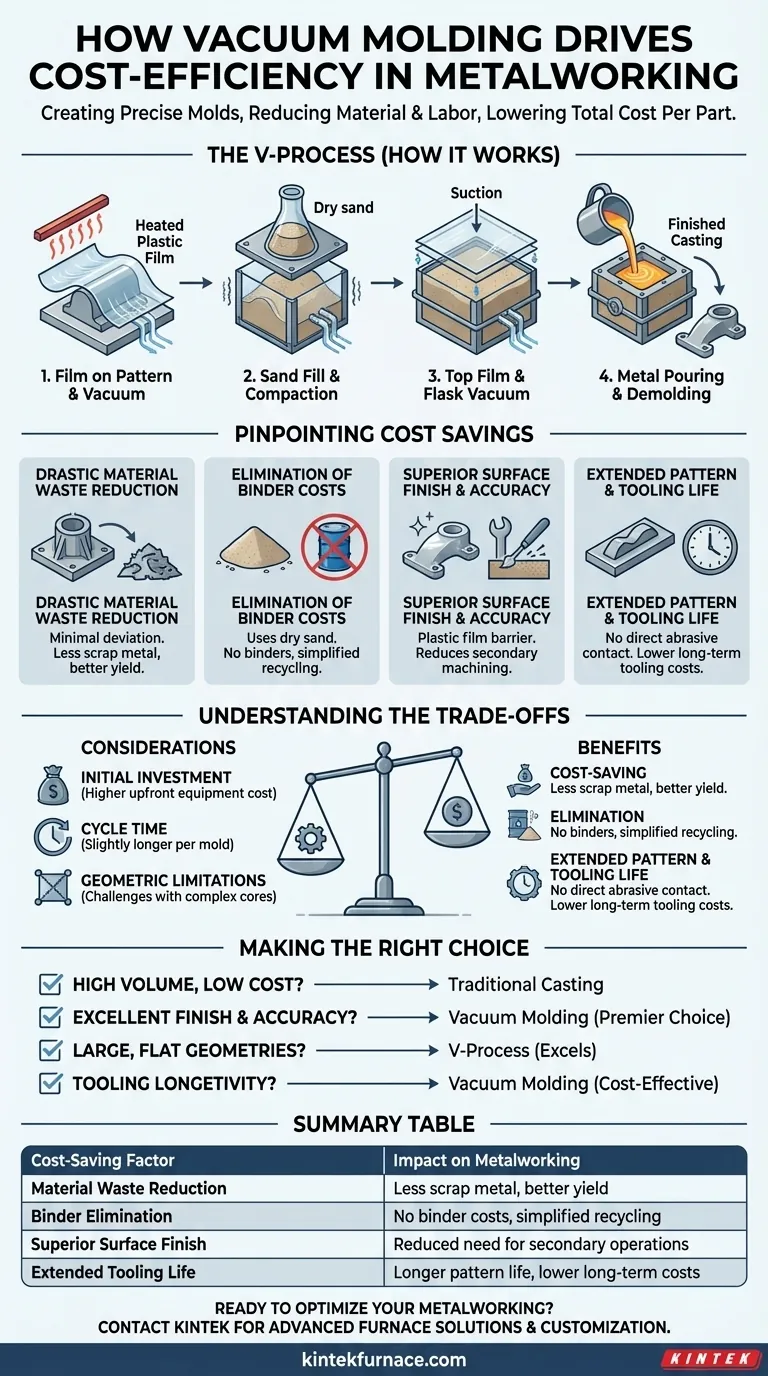

To understand the cost benefits, you must first understand the process, often called the V-Process. It is a unique form of sand casting that leverages atmospheric pressure to create a highly stable mold.

How the V-Process Works

A thin sheet of plastic film is heated and draped over a pattern (the model of the part). A vacuum is then drawn through the pattern, pulling the film tightly against every detail. A specialized flask is placed over the filmed pattern, filled with dry, binderless sand, and compacted by vibration.

Another plastic film is placed on top of the sand, and a vacuum is applied to the flask itself. This vacuum holds the sand grains rigidly in place, creating a solid, stable mold half. The vacuum on the pattern is released, and the mold is stripped. Two halves are assembled to create the final mold cavity for metal pouring.

Key Differences from Traditional Casting

Unlike conventional sand casting, which relies on clay and water (green sand) or chemical binders to hold sand together, the V-Process uses only dry sand and vacuum pressure. This fundamental difference is the source of its primary advantages.

Pinpointing the Sources of Cost Savings

The efficiency of vacuum molding isn't from a single factor, but from a cascade of improvements throughout the manufacturing workflow.

Drastic Reduction in Material Waste

The high stability and accuracy of the vacuum-formed mold allow for castings with minimal deviation from the final desired shape. This reduces the need for oversized gates, risers, and other feeders that become scrap metal, leading to better material yield.

Elimination of Binder-Related Costs

Traditional casting requires binders, mixing equipment, and often complex, energy-intensive sand reclamation systems to remove burnt chemicals. The V-Process uses clean, dry sand, which eliminates the cost of binders and simplifies the sand handling and recycling process significantly.

Superior Surface Finish and Accuracy

The plastic film acts as a perfect barrier between the molten metal and the sand, resulting in an exceptionally smooth surface finish. This quality often eliminates the need for costly and time-consuming secondary operations like shot blasting, grinding, and machining.

Extended Pattern and Tooling Life

Because the pattern never comes into direct, abrasive contact with the sand, it experiences virtually no wear. This allows patterns, even those made from less durable materials like wood or plastic, to last for thousands of cycles, dramatically reducing long-term tooling costs.

Understanding the Trade-offs

No single process is perfect for every application. While highly efficient, vacuum molding has specific considerations you must weigh.

Initial Equipment Investment

Implementing a V-Process line requires an investment in vacuum pumps, specialized flasks, and film-handling equipment. This upfront cost can be higher than that for a basic green sand casting setup.

Cycle Time Considerations

The steps of heating and applying the film, drawing the vacuum, and flask handling can result in a slightly longer cycle time per mold compared to highly automated, high-speed green sand lines. This makes it less ideal for mass-producing millions of very simple, low-cost parts.

Geometric Limitations

While excellent for many designs, parts with extremely complex internal cores or deep, thin sections can be challenging. The process is best suited for medium-to-large castings where surface finish and dimensional accuracy are critical.

Making the Right Choice for Your Project

Selecting the correct molding process requires aligning its strengths with your project's primary goals.

- If your primary focus is high-volume, low-cost simple parts: Traditional high-speed green sand or die casting may offer a lower cost per part due to faster cycle times.

- If your primary focus is excellent surface finish and dimensional accuracy: Vacuum molding is a premier choice, as it can drastically reduce or eliminate expensive machining costs.

- If your primary focus is casting large, relatively flat geometries: The V-Process excels in these applications, delivering superior stability and finish over large surface areas.

- If your primary focus is tooling longevity and lower consumable costs: The minimal pattern wear and binderless sand system make vacuum molding highly cost-effective over the long term.

Understanding these core principles allows you to select the most efficient and profitable manufacturing path for your specific application.

Summary Table:

| Cost-Saving Factor | Impact on Metalworking |

|---|---|

| Material Waste Reduction | Less scrap metal, better yield |

| Binder Elimination | No binder costs, simplified sand recycling |

| Superior Surface Finish | Reduced need for secondary operations |

| Extended Tooling Life | Longer pattern life, lower long-term costs |

Ready to optimize your metalworking process with cost-efficient solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, helping you achieve superior results and reduce operational costs. Contact us today to discuss how we can enhance your efficiency and drive your projects forward!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion