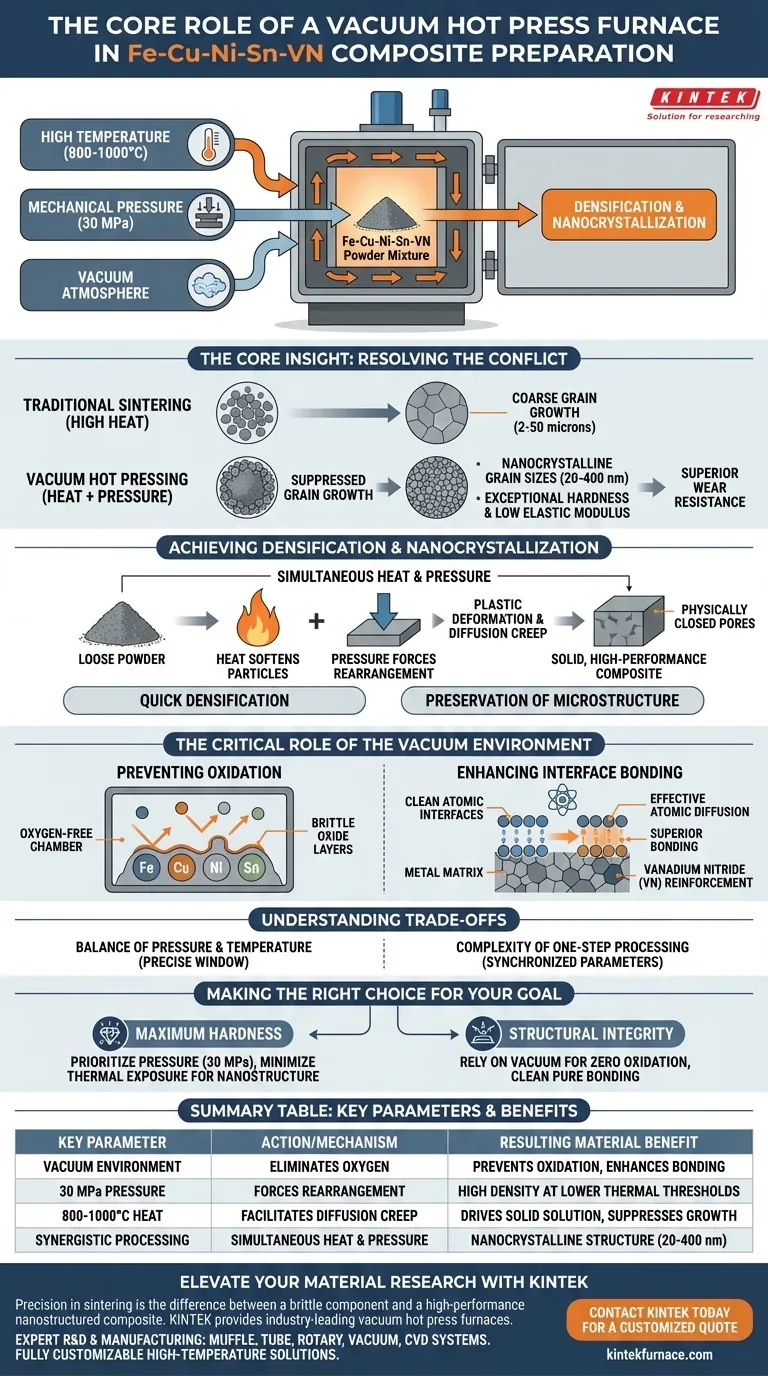

The vacuum hot press furnace acts as the definitive processing environment for synthesizing high-performance Fe-Cu-Ni-Sn-VN composites.

By simultaneously applying high temperatures (800-1000°C), mechanical pressure (30 MPa), and a vacuum atmosphere, the furnace drives densification and nanocrystallization. This process promotes the plastic deformation and diffusion creep of powder particles, resulting in a nanostructured material with exceptional hardness and low elastic modulus.

The Core Insight The vacuum hot press furnace solves the conflict between densification and grain growth. It utilizes mechanical pressure to force density at lower thermal thresholds, thereby suppressing the excessive grain growth typical of traditional sintering while ensuring a strictly oxidation-free environment.

Achieving Densification and Nanocrystallization

The primary function of this equipment is to transform loose powder into a solid, high-performance composite through a synergistic process.

Simultaneous Heat and Pressure

Unlike traditional methods that separate pressing and heating, this furnace applies both simultaneously. The 30 MPa mechanical pressure forces particles together while the 800-1000°C heat softens them.

This combination activates plastic deformation and diffusion creep. The external force physically closes internal pores and rearranges particles more effectively than thermal energy alone could achieve.

Suppressing Grain Growth

In standard sintering, maintaining high heat long enough to achieve density often causes grains to grow large, which weakens the material. The vacuum hot press furnace achieves density quickly through pressure, reducing the thermal exposure time.

This preservation of microstructure is critical. It results in nanocrystalline grain sizes (20-400 nm), whereas traditional methods often yield coarser grains (2-50 microns). The finer grain size directly correlates to superior wear resistance and hardness.

The Critical Role of the Vacuum Environment

Beyond shaping and hardening, the furnace acts as a protective chamber that dictates the chemical purity of the composite.

Preventing Oxidation

The metallic components of this composite—specifically Iron (Fe), Copper (Cu), Nickel (Ni), and Tin (Sn)—are highly susceptible to oxidation at sintering temperatures.

The vacuum environment effectively removes oxygen from the chamber. This prevents the formation of brittle oxide layers on the powder surfaces, which would otherwise compromise the structural integrity of the final part.

Enhancing Interface Bonding

By maintaining clean, oxide-free surfaces, the furnace facilitates effective atomic diffusion.

The vacuum allows for better solid solution formation between the metal matrix and the Vanadium Nitride (VN) reinforcement. This results in cleaner material interfaces and superior bonding, which are prerequisites for high tribological (wear) performance.

Understanding the Trade-offs

While the vacuum hot press furnace offers superior results, it introduces specific processing sensitivities that must be managed.

The Balance of Pressure and Temperature

The process relies on a precise "window" of operation. If the temperature is too high, you risk overriding the benefits of pressure and causing grain coarsening despite the equipment's capabilities.

Complexity of One-Step Processing

Combining sintering and densification into a single step removes the ability to inspect the part between forming and firing. All process parameters—pressure ramp-up, thermal dwell time, and vacuum levels—must be perfectly synchronized, as errors cannot be corrected in a subsequent stage.

Making the Right Choice for Your Goal

The vacuum hot press furnace is a specialized tool designed to maximize specific material properties.

- If your primary focus is Maximum Hardness: Prioritize the pressure parameters (30 MPa) to achieve full densification while keeping thermal exposure to the minimum required for bonding (maintaining the nanostructure).

- If your primary focus is Structural Integrity: Rely on the vacuum capability to ensure zero oxidation, guaranteeing that the Fe-Cu-Ni matrix bonds purely without brittle oxide inclusions.

Ultimately, this furnace is indispensable when the goal is to produce nanostructured composites that require high density without sacrificing fine grain size.

Summary Table:

| Key Process Parameter | Action/Mechanism | Resulting Material Benefit |

|---|---|---|

| Vacuum Environment | Eliminates oxygen exposure | Prevents oxidation & enhances interface bonding |

| 30 MPa Pressure | Forces particle rearrangement | High density at lower thermal thresholds |

| 800-1000°C Heat | Facilitates diffusion creep | Drives solid solution without excessive grain growth |

| Synergistic Processing | Simultaneous heat & pressure | Nanocrystalline structure (20-400 nm) |

Elevate Your Material Research with KINTEK

Precision in sintering is the difference between a brittle component and a high-performance nanostructured composite. KINTEK provides industry-leading vacuum hot press furnaces designed to solve the conflict between densification and grain growth.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique lab requirements. Whether you are developing Fe-Cu-Ni-Sn-VN alloys or advanced ceramics, our high-temperature solutions ensure oxide-free environments and precise mechanical control.

Ready to optimize your synthesis process? Contact KINTEK today for a customized quote!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does the mechanical pressure of a Vacuum Hot Press Furnace improve composite density? Elevate Performance Today

- What mold material is used for vacuum hot press sintering of aluminum matrix composites? Expert Choice Revealed

- What function does Spark Plasma Sintering (SPS) equipment serve in recycling aluminum alloy scrap? High-Value Recovery

- What are the key components of a vacuum hot press? Master Temperature, Pressure, and Atmosphere Control

- How does a vacuum hot press sintering furnace densify SiC ceramics? Achieve Near-Theoretical Density with KINTEK

- How are hot press furnaces used in sintering and consolidation? Achieve High-Density Materials Efficiently

- What are the advantages of a high-pressure vacuum induction hot press furnace? Boost SiGe Thermoelectric Performance

- What are the temperature-based classifications for vacuum hot pressing sintering furnaces? Choose the Right Furnace for Your Materials