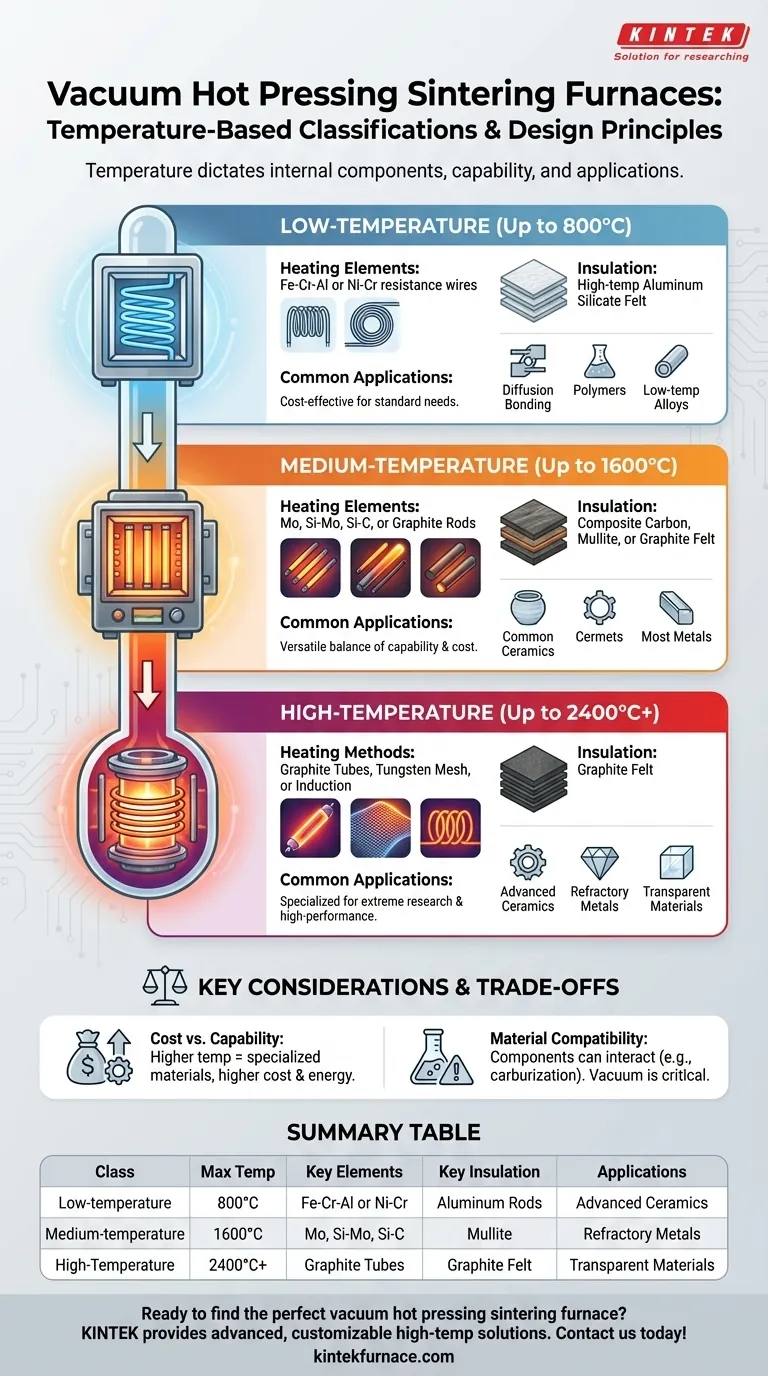

In materials science and manufacturing, the classification of vacuum hot pressing sintering furnaces is based on their maximum achievable operating temperature. These furnaces are broadly categorized into three tiers: low-temperature (up to 800°C), medium-temperature (up to 1600°C), and high-temperature (up to 2400°C or higher). This classification is not arbitrary; it is dictated by the fundamental material science of the furnace's core components, which directly determines its capabilities and applications.

The temperature rating of a vacuum hot pressing furnace is a direct reflection of its internal construction. Understanding this link—between the required temperature and the specific heating elements and insulation used—is the key to selecting the correct equipment for your material processing needs.

How Temperature Dictates Furnace Design

The maximum operating temperature of a furnace is not simply a setting. It is the physical limit of its most critical internal components: the heating elements that generate the heat and the insulation that contains it.

As the target temperature rises, the materials required for these components must become more robust, exotic, and expensive to withstand the extreme conditions.

Low-Temperature Furnaces (Up to 800°C)

This class of furnace is designed for applications that do not require extreme heat.

The construction reflects this, using well-established and cost-effective materials.

- Heating Elements: Typically use iron-chromium aluminum or nickel-chromium resistance wires.

- Insulation: Rely on high-temperature aluminum silicate felt to contain the heat effectively and efficiently at these temperatures.

Medium-Temperature Furnaces (Up to 1600°C)

This is a versatile and widely used category, capable of processing a broad range of metals and ceramics.

The materials used must be significantly more robust than those in low-temperature furnaces.

- Heating Elements: Options include metal molybdenum, silicon molybdenum rods, silicon carbon rods, or graphite rods.

- Insulation: Choices broaden to materials like composite carbon felt, mullite felt, or graphite felt, which offer superior thermal stability.

High-Temperature Furnaces (Up to 2400°C and Above)

These furnaces are specialized instruments for advanced research and the processing of high-performance materials.

Operating at such extreme temperatures requires specialized components and heating methods.

- Heating Methods: Traditional resistance elements are often replaced by graphite tubes, tungsten mesh, or non-contact induction heating.

- Insulation: Graphite felt is the standard due to its stability and excellent insulating properties in a vacuum at very high temperatures.

Understanding the Trade-offs

Choosing a furnace involves more than just matching a temperature rating. You must consider the inherent trade-offs that come with each classification.

Cost vs. Capability

There is a direct and steep correlation between a furnace's maximum temperature and its cost. High-temperature furnaces utilize more expensive, specialized materials (like tungsten or high-purity graphite) and have higher energy consumption, increasing both capital and operational expenses.

Material Compatibility

The furnace's internal components can interact with the material being processed. For example, graphite heating elements in a high-temperature furnace can lead to the carburization (introduction of carbon) of certain metals, which may be undesirable. The vacuum environment itself is critical for preventing oxidation in sensitive materials.

Atmosphere vs. Vacuum

While this guide focuses on vacuum furnaces, it is important to know that atmospheric hot-press furnaces also exist. A vacuum is essential for materials that are reactive with oxygen or other gases. Atmospheric systems are used when the processing environment needs to include reactive gases or when oxidation is not a concern.

Making the Right Choice for Your Application

Your choice of furnace should be driven by the specific requirements of the materials you intend to process.

- If your primary focus is on diffusion bonding, polymers, or specific low-temperature metal alloys: A low-temperature furnace (up to 800°C) is the most cost-effective and appropriate choice.

- If your primary focus is sintering a wide range of common ceramics, cermets, and most metals: A medium-temperature furnace (up to 1600°C) provides the best balance of capability and cost for most industrial and lab applications.

- If your primary focus is research or processing advanced ceramics, refractory metals, or transparent materials: A high-temperature furnace (up to 2400°C) is necessary, representing a significant investment for specialized, high-performance goals.

Understanding these classifications empowers you to select a furnace not just by its temperature rating, but by its fundamental design and suitability for your specific material processing goals.

Summary Table:

| Temperature Classification | Max Temperature | Key Heating Elements | Key Insulation Materials | Common Applications |

|---|---|---|---|---|

| Low-Temperature | Up to 800°C | Iron-chromium aluminum, Nickel-chromium wires | High-temperature aluminum silicate felt | Diffusion bonding, Polymers, Low-temperature alloys |

| Medium-Temperature | Up to 1600°C | Metal molybdenum, Silicon molybdenum rods, Silicon carbon rods, Graphite rods | Composite carbon felt, Mullite felt, Graphite felt | Common ceramics, Cermets, Most metals |

| High-Temperature | Up to 2400°C+ | Graphite tubes, Tungsten mesh, Induction heating | Graphite felt | Advanced ceramics, Refractory metals, Transparent materials |

Ready to find the perfect vacuum hot pressing sintering furnace for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements—whether you're sintering ceramics, metals, or advanced materials. Contact us today to discuss how our tailored solutions can enhance your material processing efficiency and results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a vacuum or protective atmosphere reduce oxidation in molten metals? Prevent Oxide Inclusions for Stronger Metals

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What is the process of hot pressing? A Guide to Achieving Superior Material Density