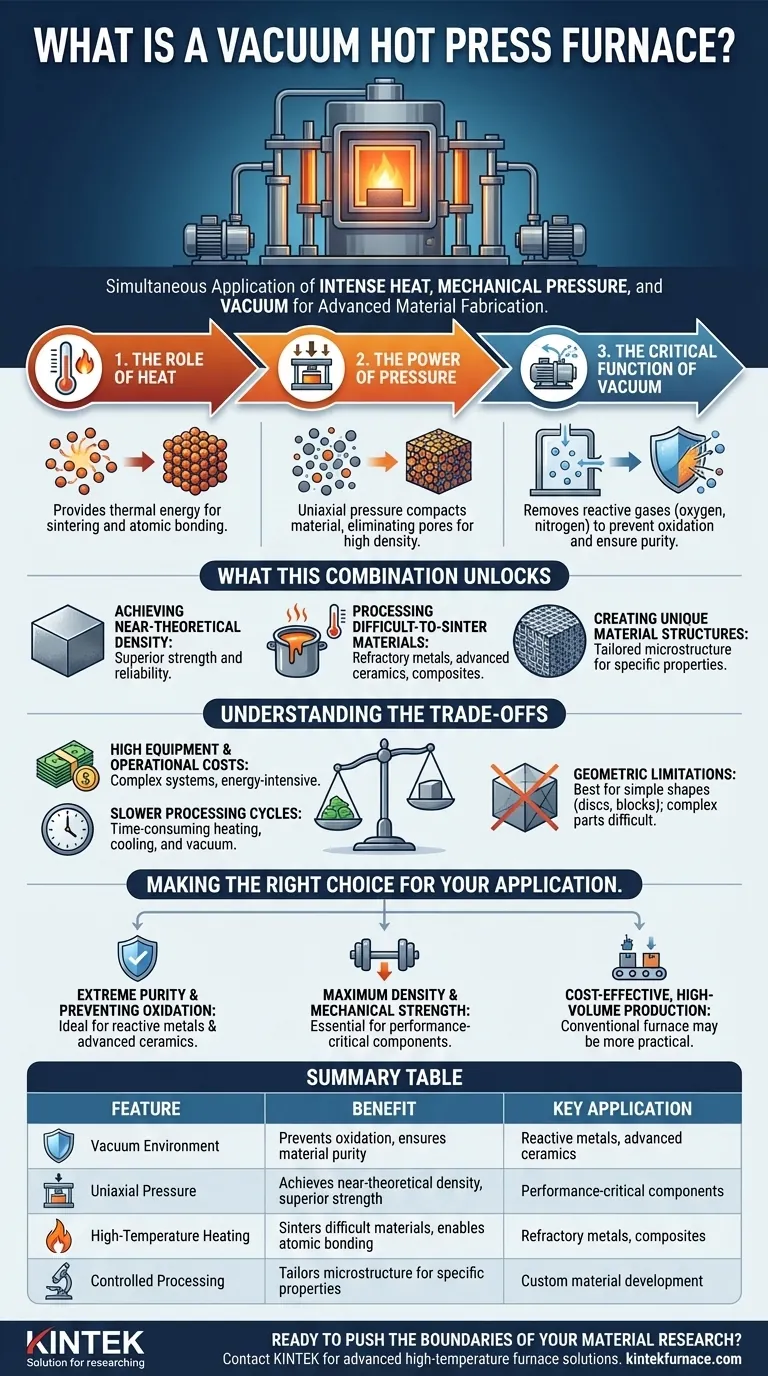

At its core, a vacuum hot press furnace is a highly specialized piece of equipment that simultaneously applies intense heat, mechanical pressure, and a vacuum to a material. This unique combination allows for the fabrication and processing of advanced materials that cannot be produced using conventional heating methods alone.

The critical insight is that a vacuum hot press doesn't just heat a material; it fundamentally reconstructs it. By removing air and applying force, it creates materials with exceptional purity, density, and strength for the most demanding applications.

How a Vacuum Hot Press Fundamentally Works

The power of this technology comes from the precise interplay of three distinct environmental controls: heat, pressure, and vacuum. Each serves a critical, non-negotiable function.

The Role of Heat

Heat provides the thermal energy necessary to soften the material. This energy allows the atoms within the material's particles to become mobile, enabling them to move and form strong bonds with neighboring particles in a process called sintering.

The Power of Pressure

While heat gets the atoms moving, uniaxial pressure (force applied along a single axis) physically compacts the material. This mechanical force squeezes out the empty spaces, or pores, between particles, dramatically accelerating the densification process.

Think of it like building a wall with bricks but no mortar. Heat allows the bricks to become slightly soft, while pressure forces them together so tightly that they fuse into a solid, seamless structure.

The Critical Function of Vacuum

The vacuum environment is arguably the most crucial element for high-performance materials. By pumping out the atmosphere, it removes reactive gases like oxygen and nitrogen. This prevents unwanted chemical reactions, such as oxidation, that can contaminate the material and severely degrade its properties.

What This Combination Unlocks

Combining these three forces enables processing capabilities that are otherwise impossible, leading to materials with superior characteristics.

Achieving Near-Theoretical Density

Many processes leave behind tiny voids or pores, which act as weak points. The immense pressure in a hot press closes these voids, allowing for the creation of components that are almost completely solid, achieving a density close to the material's theoretical maximum. This results in superior mechanical strength and reliability.

Processing Difficult-to-Sinter Materials

Many advanced ceramics, composites, and refractory metals have extremely high melting points or are highly reactive with air. A vacuum hot press is one of the few methods capable of consolidating these materials into a solid form without compromising their chemical purity or structure.

Creating Unique Material Structures

By carefully controlling the rates of heating, cooling, and pressure application, engineers can precisely tailor the final microstructure of a material. This control allows them to fine-tune properties like hardness, electrical conductivity, and thermal resistance for specific applications.

Understanding the Trade-offs

While incredibly powerful, this technology is not a universal solution. Its specialized nature comes with significant trade-offs.

High Equipment and Operational Costs

Vacuum hot press furnaces are complex and expensive to build, maintain, and operate. The systems required to generate high temperatures, high pressures, and a clean vacuum are sophisticated and energy-intensive.

Slower Processing Cycles

Achieving a deep vacuum, ramping up to temperature, applying pressure, and cooling down is a time-consuming process. This makes it unsuitable for high-volume, low-cost manufacturing where speed is a primary concern.

Geometric Limitations

The use of uniaxial pressure means this process is best suited for producing relatively simple shapes, such as discs, blocks, or cylinders. Creating complex, three-dimensional parts is often impractical or requires extensive post-processing.

Making the Right Choice for Your Application

Selecting the right material processing technique depends entirely on your end goal.

- If your primary focus is extreme material purity and preventing oxidation: The vacuum environment is the key benefit, making this furnace ideal for reactive metals and advanced ceramics.

- If your primary focus is achieving maximum density and mechanical strength: The combination of heat and high pressure is essential for eliminating porosity in performance-critical components.

- If your primary focus is cost-effective, high-volume production of simple parts: A conventional furnace using atmospheric sintering is likely a more practical and economical choice.

Ultimately, the vacuum hot press furnace is a tool for pushing the boundaries of what materials can do.

Summary Table:

| Feature | Benefit | Key Application |

|---|---|---|

| Vacuum Environment | Prevents oxidation, ensures material purity | Reactive metals, advanced ceramics |

| Uniaxial Pressure | Achieves near-theoretical density, superior strength | Performance-critical components |

| High-Temperature Heating | Sinters difficult materials, enables atomic bonding | Refractory metals, composites |

| Controlled Processing | Tailors microstructure for specific properties | Custom material development |

Ready to push the boundaries of your material research?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing capabilities to provide advanced high-temperature furnace solutions tailored to your unique needs. Our expertise in vacuum hot press technology, combined with our strong deep customization capabilities, ensures your lab has the precise equipment required to achieve superior material purity, density, and performance.

Contact us today to discuss how our vacuum hot press furnaces can accelerate your development of next-generation materials. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification