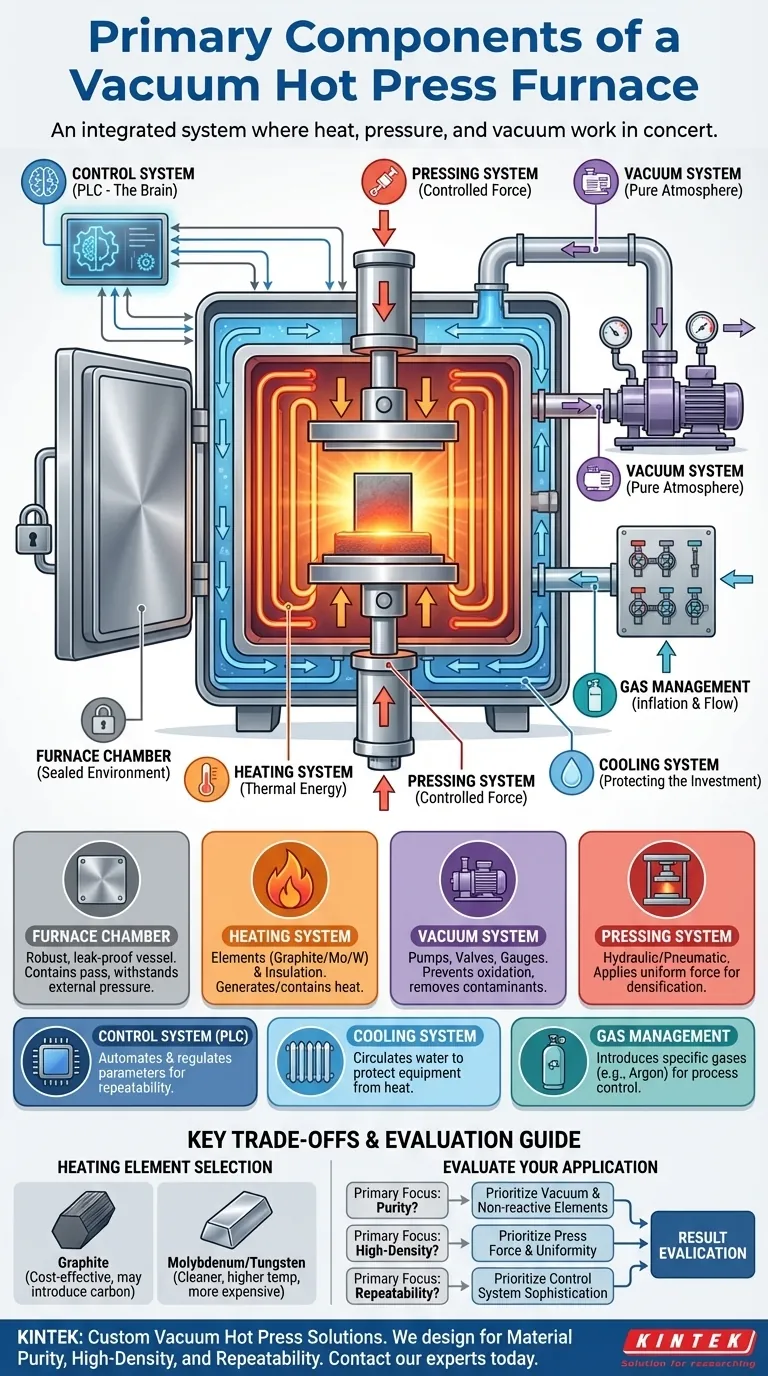

A vacuum hot press furnace is an integrated system where several distinct components work in concert to apply heat and pressure to a material within a controlled, contamination-free atmosphere. The primary components are the furnace body, a heating system, a vacuum system to create the atmosphere, and a pressure system to apply force, all governed by an overarching control system.

The defining feature of a vacuum hot press furnace is not just its individual parts, but the precise interplay between its heating, vacuum, and pressure systems. Understanding this integration is the key to achieving controlled material densification, sintering, and bonding.

The Core Systems: Heat, Pressure, and Vacuum

A vacuum hot press achieves its function through the synergy of three fundamental systems operating within a sealed chamber. The failure or inefficiency of any one system compromises the entire process.

The Furnace Chamber: The Sealed Environment

The furnace body and door form the physical structure of the system. This sealed chamber is typically constructed from durable, corrosion-resistant materials like stainless steel.

Its sole purpose is to provide a robust, leak-proof vessel that can withstand high external atmospheric pressure when a deep vacuum is drawn inside, while also containing the internal process.

The Heating System: Generating and Containing Thermal Energy

This system is responsible for bringing the material to the required process temperature. It consists of two main parts: heating elements and insulation.

Heating elements are typically made of materials like graphite, molybdenum, or tungsten, chosen based on the maximum required temperature and chemical compatibility. Insulation surrounds the heating zone to minimize heat loss and protect the furnace body, ensuring thermal efficiency and stability.

The Vacuum System: Creating a Pure Atmosphere

The vacuum system is critical for preventing oxidation and removing contaminants. It consists of a series of pumps, valves, and gauges.

First, mechanical pumps remove the bulk of the air. Then, high-vacuum pumps (like molecular or diffusion pumps) take over to achieve much lower pressures, creating a clean environment for the material being processed.

The Pressing System: Applying Controlled Force

This is the component that distinguishes a "hot press" from a standard vacuum furnace. The pressure system, which is typically hydraulic or pneumatic, applies a controlled, uniform force to the material.

This force is essential for compacting powders, promoting densification, and diffusion bonding materials together at elevated temperatures.

Essential Support and Control Systems

While the core systems perform the primary work, a set of support systems is required to manage the process, protect the equipment, and ensure repeatable results.

The Control System: The Brain of the Operation

The control system, often a Programmable Logic Controller (PLC), acts as the central nervous system.

It automates the process by precisely monitoring and regulating all critical parameters, including temperature, pressure, vacuum level, and gas flow, ensuring the process recipe is followed exactly.

The Cooling System: Protecting the Investment

A water cooling system is essential for managing the immense heat generated.

It circulates water through the furnace body and other heat-sensitive components, such as power connections and seals. This protects the equipment from thermal damage and ensures operational safety and longevity.

Gas Management: The Inflation and Flow System

This system, sometimes called an air charging or inflation system, allows for the controlled introduction of specific gases.

It can be used to backfill the chamber with an inert gas like argon or nitrogen after the vacuum cycle, which can aid in controlled cooling or create a specific process atmosphere.

Understanding Key Operational Trade-offs

The selection and configuration of these components involve critical trade-offs that directly impact furnace capability and cost. An informed decision requires understanding these balances.

Heating Element Selection

The choice of heating element material is a primary consideration. Graphite is cost-effective and common but can introduce carbon into the atmosphere, which may be undesirable for certain materials.

Molybdenum or tungsten elements provide a cleaner heating environment and can reach higher temperatures, but they come at a significantly higher cost and cannot be exposed to oxygen when hot.

Vacuum System Purity

Achieving an extremely high vacuum (e.g., 10^-6 Torr) requires more advanced and expensive pumps and meticulous chamber maintenance. For many applications, a lower-quality vacuum is sufficient and can be achieved with a simpler, more robust pump configuration.

The level of vacuum required is dictated entirely by the material's sensitivity to oxidation and contamination.

How to Evaluate Components for Your Application

Choosing the right configuration depends entirely on your end goal. Focus on the components that most directly impact your desired outcome.

- If your primary focus is material purity: The quality of your vacuum system and the choice of non-reactive heating elements are paramount.

- If your primary focus is high-density compaction: The hydraulic pressure system's maximum force, control accuracy, and pressure uniformity are your most critical components.

- If your primary focus is process repeatability: The sophistication of the integrated control system will determine your ability to achieve consistent results batch after batch.

By understanding how these distinct systems interoperate, you gain the power to precisely control your material's final properties.

Summary Table:

| Component System | Primary Function | Key Parts |

|---|---|---|

| Furnace Chamber | Provides a sealed, leak-proof vessel | Body, Door |

| Heating System | Generates and contains thermal energy | Heating Elements, Insulation |

| Vacuum System | Creates a pure, contamination-free atmosphere | Pumps, Valves, Gauges |

| Pressing System | Applies controlled, uniform force | Hydraulic/Pneumatic Mechanism |

| Control System | Automates and regulates all process parameters | PLC, Sensors |

| Cooling System | Manages heat to protect equipment | Water Cooling Circuit |

| Gas Management | Controls introduction of specific gases | Valves, Mass Flow Controllers |

Ready to Build Your Ideal Vacuum Hot Press Furnace?

Understanding the components is the first step. The next is integrating them into a system perfectly tailored to your unique research and production challenges.

KINTEK doesn't just sell furnaces; we deliver solutions. Leveraging our exceptional in-house R&D and manufacturing capabilities, we provide advanced high-temperature furnace systems built around your specific needs for material densification, sintering, and bonding.

Our deep customization expertise ensures your furnace is optimized for:

- Material Purity: With the right vacuum system and heating elements (graphite, molybdenum, tungsten) for your application.

- High-Density Compaction: Precise control over hydraulic pressure and uniformity.

- Process Repeatability: Sophisticated control systems for consistent, batch-after-batch results.

Let's discuss your application requirements. Contact our experts today to start designing your high-performance vacuum hot press solution.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What is a vacuum hot press furnace? Unlock Superior Material Performance