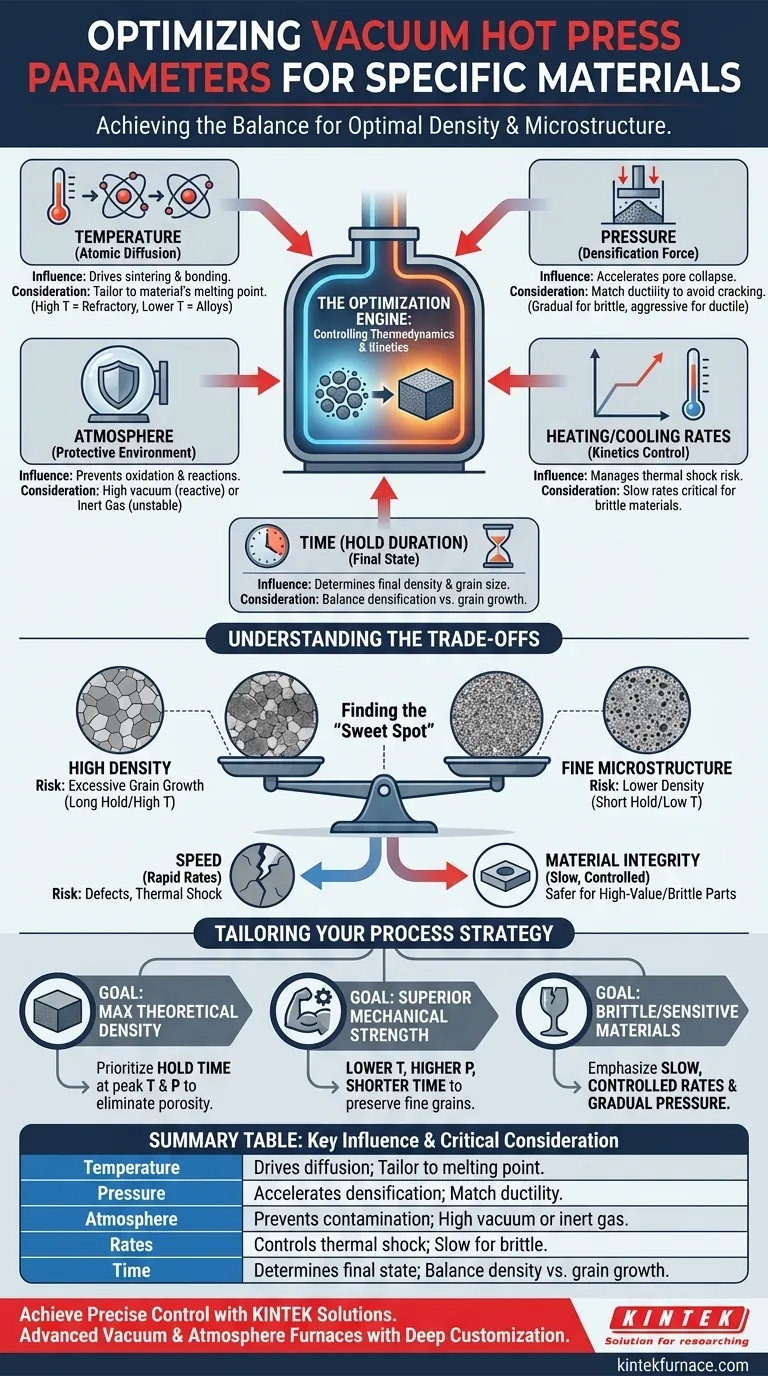

To achieve optimal results, the primary process parameters you must optimize in a vacuum hot press furnace are temperature, pressure, atmosphere (vacuum level), heating/cooling rates, and time. These variables are not independent; they must be carefully balanced and tailored to the specific chemical and physical properties of the material you are processing to achieve the desired final density and microstructure.

The core challenge of vacuum hot pressing is not simply reaching a set temperature or pressure, but controlling the entire thermodynamic and kinetic pathway. Success depends on understanding how these parameters interact to drive densification while preventing undesirable effects like grain growth or thermal shock in your specific material.

The Core Parameters and Their Material-Specific Impact

Optimizing a hot press cycle requires a deep understanding of how each parameter influences the material at a microstructural level. The furnace's high-precision control systems allow for this fine-tuning, but the strategy must be dictated by the material itself.

Temperature: The Engine of Diffusion

Temperature is the primary driver of atomic diffusion, the fundamental mechanism behind sintering and bonding. It provides the energy needed for atoms to move and for particle necks to form and grow.

The required temperature is dictated entirely by the material's properties. Refractory metals like tungsten or ceramics require extremely high temperatures, while some metal alloys can be processed at much lower heat.

Pressure: The Force of Densification

Applied pressure is the key advantage of hot pressing over simple sintering. It mechanically aids in the collapse of pores, particle rearrangement, and plastic deformation, significantly accelerating the densification process.

The amount and rate of pressure application must be matched to the material's mechanical properties. Brittle materials like ceramics may require a gradual pressure ramp to avoid cracking, while more ductile metals can handle a more aggressive approach.

Atmosphere: The Protective Environment

The furnace atmosphere is critical for preventing unwanted chemical reactions. A high vacuum is used to remove oxygen and other contaminants that could lead to oxidation, which is fatal for reactive metals and many advanced materials.

For materials that may decompose or sublimate under vacuum at high temperatures, an inert gas backfill (like Argon) is used. This creates an overpressure that stabilizes the material while still providing a clean, non-reactive environment.

Rate & Duration: The Control of Kinetics

The heating and cooling rates, as well as the hold time at peak temperature and pressure, control the kinetics of the process. These temporal parameters are just as crucial as the peak values themselves.

Rapid heating can induce thermal shock and fracture in materials with low thermal conductivity, such as large ceramic parts. Conversely, a long hold time at peak temperature, while promoting full density, can also lead to excessive grain growth, which often degrades mechanical properties like hardness and strength.

Understanding the Trade-offs and Pitfalls

Achieving a successful outcome involves navigating a series of critical trade-offs. Misunderstanding these can lead to failed parts, damaged equipment, or inconsistent results.

High Density vs. Fine Microstructure

The most common trade-off is between achieving maximum density and maintaining a fine-grained microstructure. While high temperatures and long hold times guarantee density, they are also the primary drivers of grain growth. The goal is to find the "sweet spot" that provides sufficient densification before grains begin to coarsen excessively.

Speed vs. Material Integrity

Applying pressure and temperature quickly can shorten cycle times, but it increases the risk of defects. Rapid pressure application can trap gases in closed pores, while fast heating can cause cracking. A slower, more controlled process is almost always safer for high-value or brittle components.

Inadequate Vacuum or Atmosphere Control

A poor vacuum level is a common source of failure. Even trace amounts of oxygen can form brittle oxide layers on particle surfaces, inhibiting proper diffusion bonding. This results in a part that may look solid but has poor internal cohesion and weak mechanical properties.

Tailoring Your Process to Your Material Goal

Your specific optimization strategy should be guided by your end goal. The ideal parameters for one objective are often different for another.

- If your primary focus is achieving maximum theoretical density: Prioritize optimizing the hold time at peak temperature and pressure to ensure all porosity is eliminated.

- If your primary focus is preserving a fine-grained microstructure for superior mechanical strength: Experiment with lower temperatures and higher pressures, or shorter hold times, to reach density without initiating significant grain growth.

- If your primary focus is processing thermally sensitive or brittle materials: Emphasize slow, controlled heating and cooling rates, and apply pressure gradually only after the material has reached a temperature where it has some ductility.

Ultimately, mastering your vacuum hot press furnace comes from methodically controlling these interconnected parameters to guide your material to its ideal final state.

Summary Table:

| Parameter | Key Influence on Material | Critical Consideration |

|---|---|---|

| Temperature | Drives atomic diffusion for sintering and bonding. | Must be tailored to the material's melting point and reactivity. |

| Pressure | Accelerates densification by collapsing pores. | Must match the material's ductility to avoid cracking. |

| Atmosphere | Prevents oxidation and contamination. | High vacuum for reactive materials; inert gas for unstable ones. |

| Heating/Cooling Rate | Controls thermal shock risk and kinetics. | Slow rates are critical for brittle materials like ceramics. |

| Time (Hold Duration) | Determines final density and grain size. | Balances full densification against excessive grain growth. |

Achieve precise control over your material's properties with a furnace built for your specific challenges.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Let our experts help you optimize your hot pressing process. Contact KINTEL today to discuss your application and discover how our tailored vacuum hot press solutions can enhance your R&D and production outcomes.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability