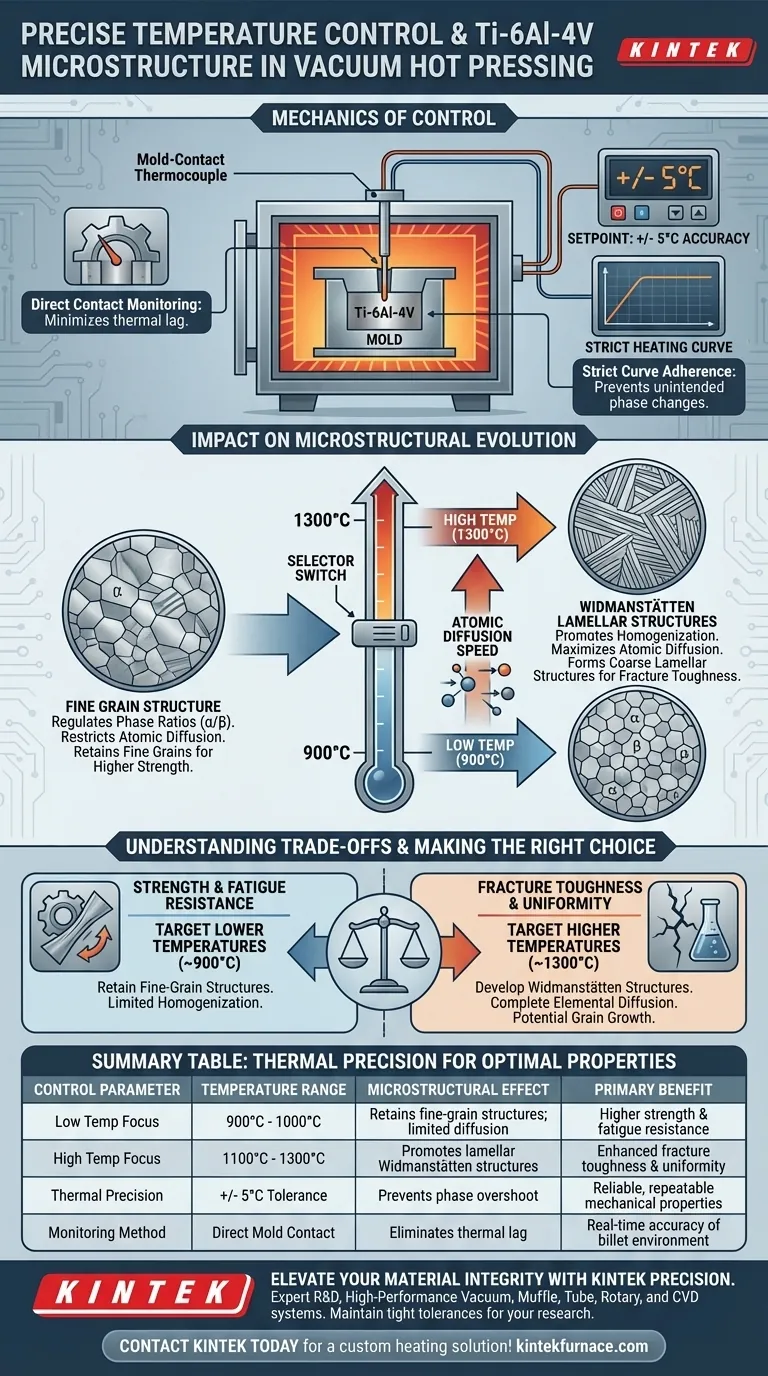

High-precision temperature control utilizing mold-contact thermocouples is the primary mechanism for dictating the internal architecture of Ti-6Al-4V during vacuum hot pressing. By maintaining accuracy within +/- 5°C, these systems strictly enforce thermal curves that control atomic diffusion rates, directly establishing the ratio of alpha to beta phases, the final grain size, and the formation of specific Widmanstätten structures.

Precise thermal management does not merely heat the material; it acts as a selector switch for microstructural properties. By adjusting temperatures between 900°C and 1300°C, you effectively choose between retaining fine-grain structures or promoting complete homogenization and lamellar formations.

The Mechanics of Control

Direct Contact Monitoring

Thermocouples achieve high precision by maintaining direct contact with the mold. This configuration minimizes the lag between the heat source and the measurement, ensuring the environment surrounding the billet accurately reflects the controller's data.

Strict Curve Adherence

The system leverages this feedback to maintain accuracy up to +/- 5°C. This tight tolerance ensures the process strictly follows the preset heating curve, preventing thermal overshoots that could trigger unintended phase changes.

Impact on Microstructural Evolution

Regulating Phase Ratios

The operating temperature range, specifically between 900°C and 1300°C, directly determines the proportion of alpha and beta phases within the alloy. Controlling this ratio is the fundamental step in tailoring the material's mechanical response.

Driving Atomic Diffusion

Temperature dictates the speed of atomic diffusion. Precise control allows operators to dial in the exact amount of energy required to achieve the desired level of chemical homogenization across the material.

Formation of Lamellar Structures

At higher temperatures within the processing window, the system promotes the formation of Widmanstätten lamellar structures. These specific microstructural arrangements are critical for applications requiring distinct fracture toughness characteristics.

Understanding the Trade-offs

Fine Grains vs. Homogenization

There is an inherent trade-off between grain size and diffusion. Lower temperatures help retain fine-grain structures, which generally offer higher strength. However, lower temperatures reduce atomic diffusion rates, potentially leaving the material less homogenized.

The Consequence of High Heat

Conversely, higher temperatures (approaching 1300°C) ensure complete elemental diffusion and uniformity. The downside is the promotion of grain growth and the transition to coarse lamellar microstructures, which may alter the alloy's ductility and fatigue performance.

Making the Right Choice for Your Goal

To optimize the vacuum hot pressing process, you must align your temperature setpoints with your specific mechanical requirements:

- If your primary focus is high strength and fatigue resistance: Target lower temperatures (closer to 900°C) to restrict diffusion and retain fine-grain structures.

- If your primary focus is fracture toughness and chemical uniformity: target higher temperatures (up to 1300°C) to maximize atomic diffusion and develop fully formed Widmanstätten lamellar structures.

Ultimately, the thermocouple provides the precision necessary to navigate the narrow window between these competing microstructural states.

Summary Table:

| Control Parameter | Temperature Range | Microstructural Effect | Primary Benefit |

|---|---|---|---|

| Low Temp Focus | 900°C - 1000°C | Retains fine-grain structures; limited diffusion | Higher strength & fatigue resistance |

| High Temp Focus | 1100°C - 1300°C | Promotes lamellar Widmanstätten structures | Enhanced fracture toughness & uniformity |

| Thermal Precision | +/- 5°C Tolerance | Prevents phase overshoot | Reliable, repeatable mechanical properties |

| Monitoring Method | Direct Mold Contact | Eliminates thermal lag | Real-time accuracy of billet environment |

Elevate Your Material Integrity with KINTEK Precision

Microstructural perfection in Ti-6Al-4V demands absolute thermal control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, Rotary, and CVD systems designed to maintain the tight tolerances your research requires. Whether you need to retain fine-grain strength or achieve complete chemical homogenization, our lab high-temp furnaces are fully customizable for your unique processing needs.

Ready to optimize your vacuum hot pressing results? Contact KINTEK today to consult with our experts on a custom heating solution!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the advantages of using a VHP furnace over CVD for ZnS? Boost Strength and Efficiency with Vacuum Hot Pressing

- What role does a Spark Plasma Sintering (SPS) system play in the preparation of Al0.3CoCrFeNiMo0.75 bulk materials?

- What are the temperature-based classifications for vacuum hot pressing sintering furnaces? Choose the Right Furnace for Your Materials

- What are the main advantages of hot pressing in powder metallurgy? Achieve High-Density, Fine-Grained Components

- What roles do high-strength graphite molds play during the hot-pressing sintering of TiAl-SiC composites?

- What is the primary function of a vacuum hot pressing sintering furnace? Achieving High-Density CoCrFeNi(Cu) Coatings

- Why are precision vacuum ovens required for reactor hot-press bonding? Ensure Leak-Free High-Pressure Integrity

- What are the technical advantages of Spark Plasma Sintering (SPS) for maraging steel? Achieve Rapid Densification