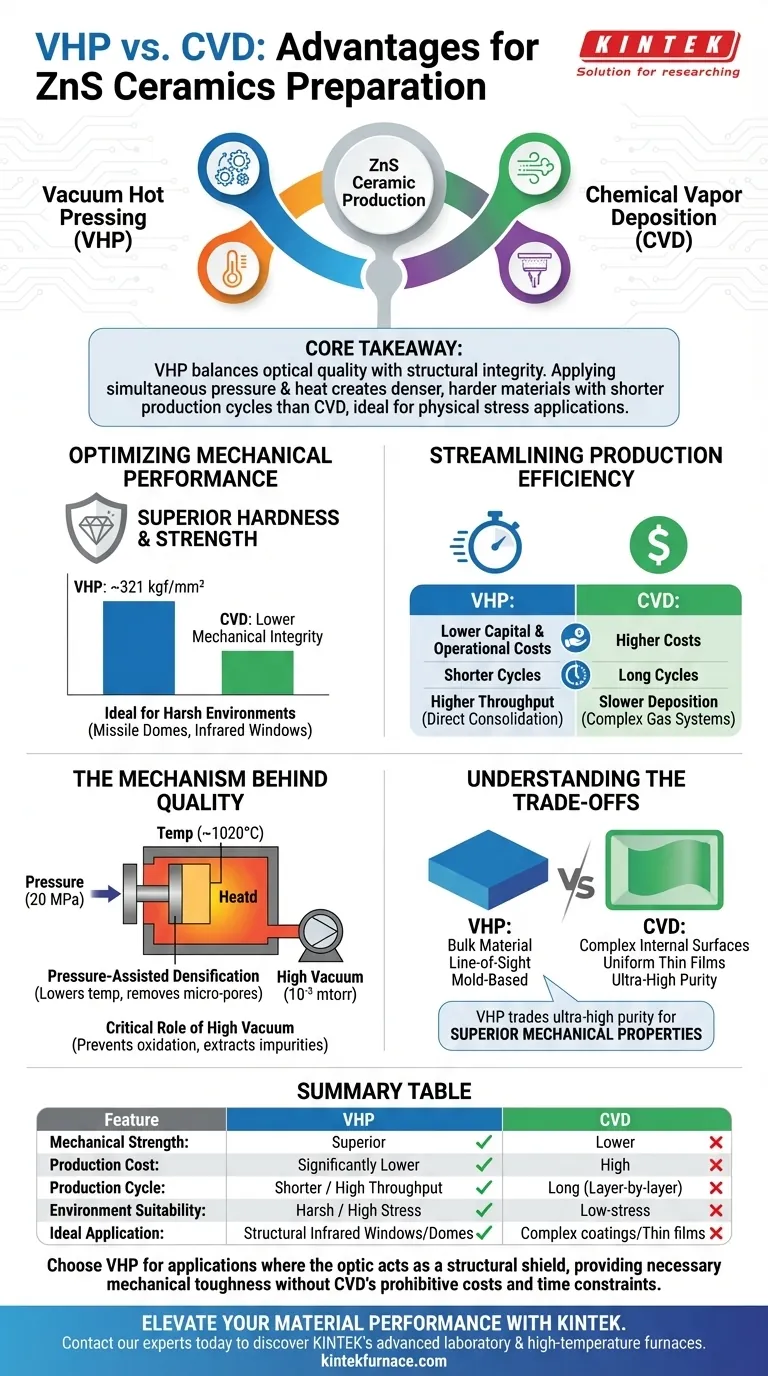

Vacuum Hot Pressing (VHP) offers a distinct advantage in both economic efficiency and mechanical performance when compared to Chemical Vapor Deposition (CVD). While CVD is known for high purity, VHP provides a significantly simpler, lower-cost production route that yields Zinc Sulfide (ZnS) ceramics with superior hardness and mechanical strength, making them better suited for physically demanding environments.

Core Takeaway VHP balances optical quality with structural integrity. By applying simultaneous pressure and heat, VHP creates a denser, harder material with a shorter production cycle than CVD, making it the preferred method for applications where the component must withstand physical stress, such as missile domes or protective infrared windows.

Optimizing Mechanical Performance

Superior Hardness and Strength

The most critical performance advantage of VHP over CVD is mechanical integrity. VHP-prepared ceramics exhibit significantly higher hardness—reaching levels such as 321 kgf/mm².

Suitability for Harsh Environments

Because CVD-prepared ceramics generally possess weaker mechanical properties, they are less ideal for applications involving physical impact or stress. The optimized microstructure achieved through VHP makes these materials the standard for infrared window applications that require high mechanical strength to survive harsh operating conditions.

Streamlining Production Efficiency

Lower Capital and Operational Costs

The VHP process is generally simpler and requires less expensive equipment than CVD. CVD involves complex gas handling systems and slower deposition rates, whereas VHP utilizes a more direct consolidation method, resulting in significantly lower overall production costs.

Shorter Production Cycles

CVD is inherently a slow process, often requiring long durations to grow materials atom-by-atom or layer-by-layer. VHP achieves densification much faster, offering a shorter production cycle that enhances throughput and scalability for bulk ceramic manufacturing.

The Mechanism Behind the Quality

Pressure-Assisted Densification

VHP utilizes a synergy of high temperature (approx. 1020°C) and significant mechanical pressure (e.g., 20 MPa). This pressure lowers the temperature required for densification and forcibly removes micro-pores, allowing the material to reach near-theoretical density without the excessive grain growth that can weaken ceramics.

Critical Role of High Vacuum

Operating in a high vacuum environment (e.g., 10⁻³ mtorr) is essential for ZnS processing. This environment prevents the oxidation and decomposition of Zinc Sulfide at high temperatures. Furthermore, it extracts volatile impurities and adsorbed gases from the powder interstices, reducing porosity and ensuring the high infrared transmittance required for optical applications.

Understanding the Trade-offs

Geometry vs. Bulk Material

While VHP is superior for creating strong, bulk ceramic plates or domes, it is a line-of-sight, mold-based process. It cannot match CVD's ability to coat complex internal surfaces or irregular shapes with a thin, uniform film.

Purity vs. Strength

CVD creates material via molecular deposition, resulting in extremely high purity. VHP consolidates powder, meaning the purity is dictated by the starting raw material. However, VHP trades this ultra-high purity for the superior mechanical properties necessary for structural optical components.

Making the Right Choice for Your Goal

When selecting between VHP and CVD for Zinc Sulfide production, align your choice with the component's primary function:

- If your primary focus is mechanical durability in harsh environments: Choose VHP for its ability to produce harder, denser ceramics capable of withstanding physical stress (e.g., missile domes).

- If your primary focus is cost-efficiency and speed: Choose VHP to leverage shorter production cycles and lower equipment costs compared to the slow deposition times of CVD.

Summary: For applications where the optic acts as a structural shield, VHP provides the necessary mechanical toughness without the prohibitive costs and time constraints of CVD.

Summary Table:

| Feature | Vacuum Hot Pressing (VHP) | Chemical Vapor Deposition (CVD) |

|---|---|---|

| Mechanical Strength | Superior (Hardness ~321 kgf/mm²) | Lower mechanical integrity |

| Production Cost | Significantly Lower | High (Complex gas systems) |

| Production Cycle | Shorter / High Throughput | Long (Layer-by-layer growth) |

| Environment Suitability | Harsh / High Physical Stress | Low-stress environments |

| Ideal Application | Structural infrared windows/domes | Complex coatings/Thin films |

Elevate Your Material Performance with KINTEK

Are you looking to optimize the mechanical integrity and production efficiency of your ZnS ceramics? KINTEK provides industry-leading thermal processing solutions designed to meet your most demanding specifications. Backed by expert R&D and precision manufacturing, we offer high-performance VHP, CVD, Muffle, Tube, Rotary, and Vacuum systems—all fully customizable to your unique research or industrial needs.

Don't compromise on durability or cost. Contact our experts today to discover how KINTEK’s advanced laboratory and high-temperature furnaces can streamline your production and enhance your material quality.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the primary function of the vacuum environment in a vacuum hot press furnace during titanium alloy processing? Prevent Embrittlement for Superior Ductility

- What role does Hexagonal Boron Nitride (h-BN) coating play in SPS molds? Protect Your Tooling and Purity

- What are the benefits of a heat press machine? Achieve Professional, Durable Results

- What are the key benefits of using Vacuum Hot Press equipment in manufacturing? Achieve Superior Material Quality and Performance

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance

- How does precise temperature control in a Vacuum Hot Press Furnace influence the microstructure of Al-Ti system materials? Achieve Superior Microstructural Integrity

- How does the pressure-assisted mechanism in a Vacuum Hot Press Furnace improve YAG ceramics? Unlock Optical Clarity

- What role do vacuum presses play in plastic forming and lamination? Essential Guide for Precision Fabrication