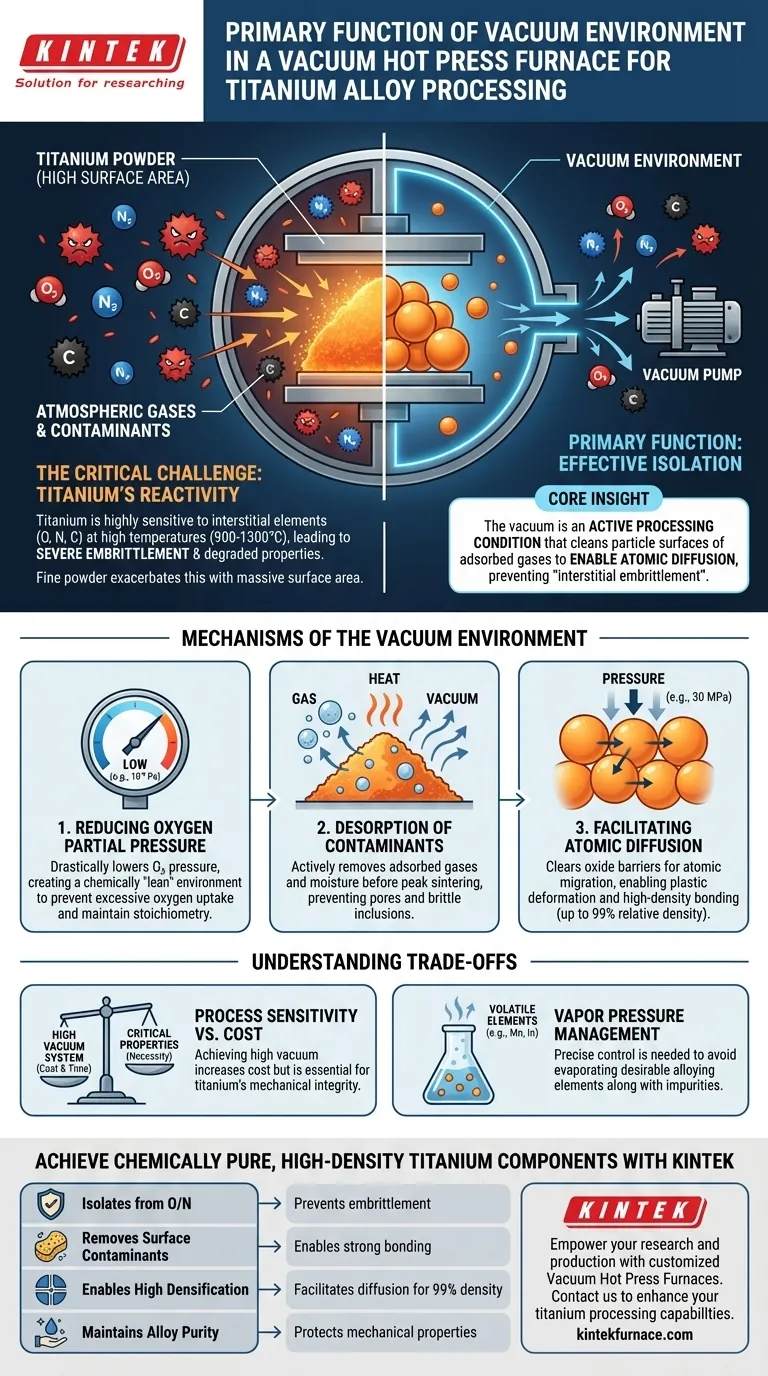

The primary function of the vacuum environment in a vacuum hot press furnace is to effectively isolate chemically reactive titanium from atmospheric gases, specifically oxygen, nitrogen, and carbon.

Because titanium and its alloys possess high chemical activity at elevated temperatures (e.g., 900–1300°C), they act as "getters" for impurities. The vacuum reduces the partial pressure of these gases to prevent oxidation, nitridation, and the absorption of interstitial elements, which would otherwise cause severe embrittlement and degrade the material's mechanical properties.

Core Insight: The vacuum is not merely a passive void; it is an active processing condition that cleanses particle surfaces of adsorbed gases to enable atomic diffusion. Without this high-vacuum isolation, titanium suffers from "interstitial embrittlement," where microscopic impurities ruin the alloy's ductility and structural integrity regardless of the pressure applied.

The Critical Challenge: Titanium's Reactivity

The Sensitivity to Interstitial Elements

Titanium is uniquely sensitive to "interstitial elements"—small atoms like oxygen, nitrogen, and carbon that fit between the metal's crystal lattice.

At the high temperatures required for sintering (1150°C to 1250°C), titanium absorbs these elements rapidly. Even trace amounts can lead to the formation of brittle compounds, such as oxides and nitrides, which drastically reduce the ductility and fatigue life of the final component.

The Surface Area Factor

This sensitivity is exacerbated when processing titanium powders rather than bulk material.

Fine powder particles possess a massive specific surface area relative to their volume. This provides a large interface for gas adsorption and oxidation. Without a vacuum, the heat would cause these surface oxides to thicken, preventing the particles from bonding together effectively.

Mechanisms of the Vacuum Environment

Reducing Oxygen Partial Pressure

The vacuum hot press creates an environment with extremely low pressure (e.g., 10^-1 mbar to 9.9x10^-5 Pa).

By drastically lowering the oxygen partial pressure, the furnace ensures that the environment is chemically "lean." This prevents the titanium from taking up excessive oxygen during the heating and holding phases, maintaining the chemical stoichiometry of the alloy.

Desorption of Contaminants

Before the material reaches peak sintering temperature, the vacuum serves to "clean" the raw material.

It actively removes adsorbed gases and moisture from the surface of the pre-alloyed powders. Removing these volatile contaminants is a prerequisite for high-quality sintering, as trapped gases would otherwise create pores or brittle inclusions within the metal matrix.

Facilitating Atomic Diffusion

For a hot press to work, atoms must migrate across particle boundaries to fuse the powder into a solid mass.

Surface oxides act as a barrier to this diffusion. By preventing oxidation and removing surface impurities, the vacuum "clears the obstacles" for atomic migration. This allows the heat and axial pressure (e.g., 30 MPa) to facilitate plastic deformation and metallurgical bonding, leading to relative densities up to 99%.

Understanding the Trade-offs

Process Sensitivity vs. Equipment Cost

Achieving the high vacuum levels mentioned (such as 9.9x10^-5 Pa) requires sophisticated pumping systems and meticulous seal integrity.

This increases the capital cost and cycle time of the process compared to inert gas sintering. However, for titanium, this is rarely an optional trade-off; the degradation of mechanical properties in a non-vacuum environment makes lower-cost alternatives non-viable for critical applications.

Vapor Pressure Management

While the vacuum removes unwanted gases, operators must be aware of the vapor pressure of specific alloying elements.

In complex alloys containing volatile elements (similar to Manganese or Indium in other systems), high vacuum at high temperatures can risking evaporating desirable elements along with the impurities. Precise control of the vacuum level and heating rate is required to balance purification with compositional stability.

Making the Right Choice for Your Goal

The vacuum level and processing parameters should be tuned to your specific outcome requirements.

- If your primary focus is Maximum Ductility: Prioritize the highest possible vacuum levels (lowest pressure) to minimize interstitial oxygen pickup, as this is the primary driver of embrittlement.

- If your primary focus is High Density/Wear Resistance: Focus on the synergy between vacuum and temperature to ensure oxide barriers are removed, facilitating the atomic diffusion necessary for 99% densification.

- If your primary focus is Alloy Purity: Ensure the vacuum system is capable of sustained operation at high temperatures to prevent re-oxidation or nitridation during the critical holding phases.

The vacuum environment is the fundamental enabler of titanium powder metallurgy, transforming a highly reactive powder into a chemically pure, structurally sound, and ductile component.

Summary Table:

| Function | Benefit for Titanium Alloy |

|---|---|

| Isolates from Oxygen/Nitrogen | Prevents oxidation & nitridation that cause severe embrittlement |

| Removes Surface Contaminants | Cleans powder surfaces, enabling atomic diffusion for strong bonding |

| Enables High Densification | Facilitates plastic deformation and bonding under pressure for up to 99% density |

| Maintains Alloy Purity | Protects the chemical stoichiometry and mechanical properties of the final component |

Achieve Chemically Pure, High-Density Titanium Components with KINTEK

Processing reactive metals like titanium requires precise environmental control to prevent embrittlement and ensure structural integrity. Backed by expert R&D and manufacturing, KINTEK offers Vacuum Hot Press Furnaces and other lab high-temp systems, all customizable for your unique material processing needs.

Let our solutions empower your research and production:

- Prevent Interstitial Embrittlement: Our vacuum systems create the high-purity environment necessary for ductile titanium alloys.

- Achieve Superior Densification: Optimize sintering parameters for maximum density and performance.

- Customize for Your Application: Whether your focus is maximum ductility, wear resistance, or alloy purity, we can tailor a furnace to your exact specifications.

Contact us today to discuss how a KINTEK Vacuum Hot Press Furnace can enhance your titanium processing capabilities!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures