Precise temperature control is the governing factor in determining the microstructural integrity of Aluminum-Titanium (Al-Ti) system materials during Vacuum Hot Pressing (VHP). It directly regulates the reaction diffusion rate, ensuring the complete conversion of reactants into beneficial intermediate phases like Al3Ti while preventing the formation of structural defects caused by rapid exothermic reactions.

In Al-Ti material synthesis, temperature precision acts as the throttle for chemical reactivity. It orchestrates the delicate balance between liquid aluminum wetting and solid titanium consumption, determining whether the final product is a dense, uniform alloy or a porous, brittle failure.

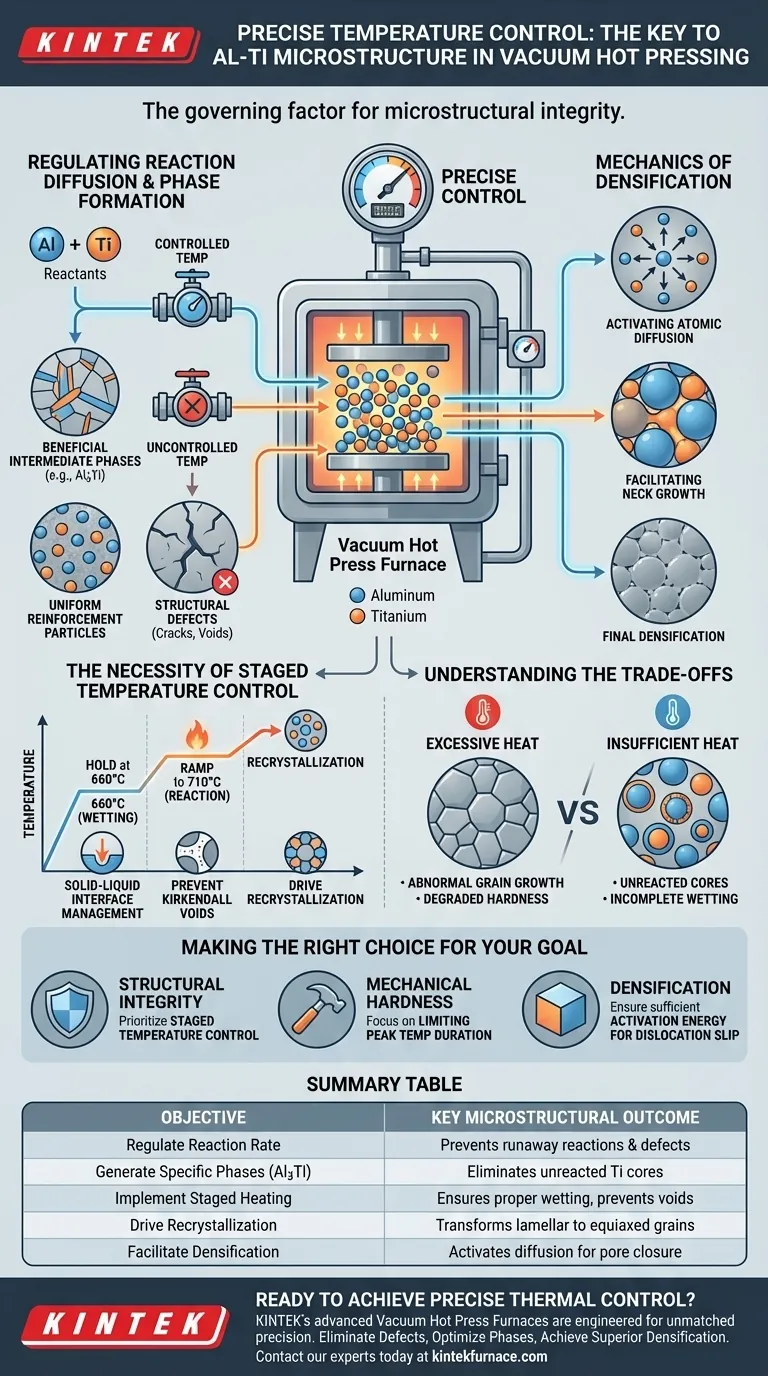

Regulating Reaction Diffusion and Phase Formation

Controlling the Reaction Rate

The reaction diffusion rate between Aluminum and Titanium is highly sensitive to thermal inputs. Precise regulation allows you to manage the speed at which these elements interact, preventing runaway reactions.

Generating Specific Intermediate Phases

Targeted temperature set-points enable the complete conversion of Titanium into specific intermetallic compounds, such as Al3Ti. This control is critical for eliminating unreacted Titanium cores, which would otherwise create weak points within the material matrix.

optimizing Reinforcement Particles

By maintaining strict thermal parameters, you dictate the quantity and size of the reinforcement phase particles. This ensures a uniform distribution of the harder phases necessary for the material's mechanical strength.

The Necessity of Staged Temperature Control

Managing the Solid-Liquid Interface

Implementing a staged heating profile—such as holding at 660°C before ramping to 710°C—is essential for success. This specific staging allows liquid aluminum to sufficiently wet the titanium interface before the reaction accelerates.

Preventing Kirkendall Voids

If the temperature rises too quickly, the reaction rate becomes excessive, leading to the formation of Kirkendall voids and cracks. A controlled, steady reaction minimizes these defects, ensuring a solid, continuous interface rather than a porous one.

Driving Recrystallization

The continuous thermal energy supplied by the VHP furnace provides the driving force for recrystallization. This transforms rapidly solidified lamellar structures into uniform, fine equiaxed alpha grains and intergranular beta phases.

Mechanics of Densification

Activating Atomic Diffusion

High-precision temperature control provides the stable environment needed to activate atomic diffusion and dislocation slip. This thermal energy is required to induce the formation of Shockley partial dislocations and stacking faults.

Facilitating Neck Growth

These dislocation mechanisms dominate the initial growth of particle contact necks. As the contact area expands, the material achieves final densification, a process that works in tandem with the applied pressure field.

Understanding the Trade-offs

The Risk of Excessive Heat

While high temperatures facilitate better diffusion and density, exceeding the optimal window can trigger abnormal grain growth. This results in a coarse microstructure that significantly degrades the hardness and fracture toughness of the tool or component.

The Risk of Insufficient Heat

Conversely, failing to reach or maintain the critical reaction temperature results in incomplete wetting and unreacted cores. Without the necessary thermal activation energy, the material cannot achieve full pore closure or the desired phase transformation, rendering the VHP process ineffective.

Making the Right Choice for Your Goal

To optimize the microstructure of Al-Ti composites, you must align your thermal strategy with your specific material objectives.

- If your primary focus is Structural Integrity: Prioritize staged temperature control (e.g., a hold at 660°C) to ensure full wetting and minimize void formation before the main reaction occurs.

- If your primary focus is Mechanical Hardness: Focus on limiting the peak temperature duration to prevent abnormal grain growth while ensuring enough heat is present for complete phase conversion (Al3Ti).

- If your primary focus is Densification: Ensure the temperature provides sufficient activation energy for dislocation slip, allowing particle necks to grow and pores to close effectively under axial pressure.

Ultimately, the microstructure of an Al-Ti system is not defined by the maximum temperature reached, but by the precision of the thermal path taken to get there.

Summary Table:

| Temperature Control Objective | Key Microstructural Outcome |

|---|---|

| Regulate Reaction Rate | Prevents runaway reactions and structural defects like cracks. |

| Generate Specific Phases (e.g., Al3Ti) | Eliminates unreacted Titanium cores for a uniform, strong matrix. |

| Implement Staged Heating | Ensures proper aluminum wetting and prevents Kirkendall voids. |

| Drive Recrystallization | Transforms lamellar structures into fine, uniform equiaxed grains. |

| Facilitate Densification | Activates atomic diffusion and dislocation slip for pore closure. |

Ready to achieve precise thermal control for your advanced material synthesis?

Your research on Al-Ti systems demands a furnace that offers unmatched temperature precision and stability to perfect phase formation and material density. KINTEK's advanced Vacuum Hot Press Furnaces are engineered for exactly this level of control, enabling you to execute complex thermal profiles with confidence.

We help you:

- Eliminate Defects: Precisely manage reaction kinetics to prevent voids and cracks.

- Optimize Phases: Ensure complete conversion to desired intermetallics like Al3Ti.

- Achieve Superior Densification: Activate the necessary diffusion mechanisms for pore-free materials.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique research needs.

Contact our experts today to discuss how a KINTEK furnace can be tailored to your specific Al-Ti material goals.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What roles do graphite molds play during the SPS of MgTiO3-CaTiO3? Achieve Rapid Densification and Precision

- What core role does a vacuum hot press furnace play in the densification process of copper-carbon nanotube composites? Achieve High-Performance Cu-CNT Materials

- How does the heating mechanism of Spark Plasma Sintering (SPS) function? Enhance TiC/SiC Composite Fabrication

- What are the main types of vacuum presses? Discover the Right Press for Your Materials and Applications

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- What is the function of a rigid mould in vacuum hot pressing? Master Structural Precision in Layered Composites

- What are the advantages of using a vacuum hot pressing furnace compared to explosive cladding? Get Precision Results

- How does the capability for long-duration temperature control in a vacuum hot pressing furnace improve ZnS ceramics?