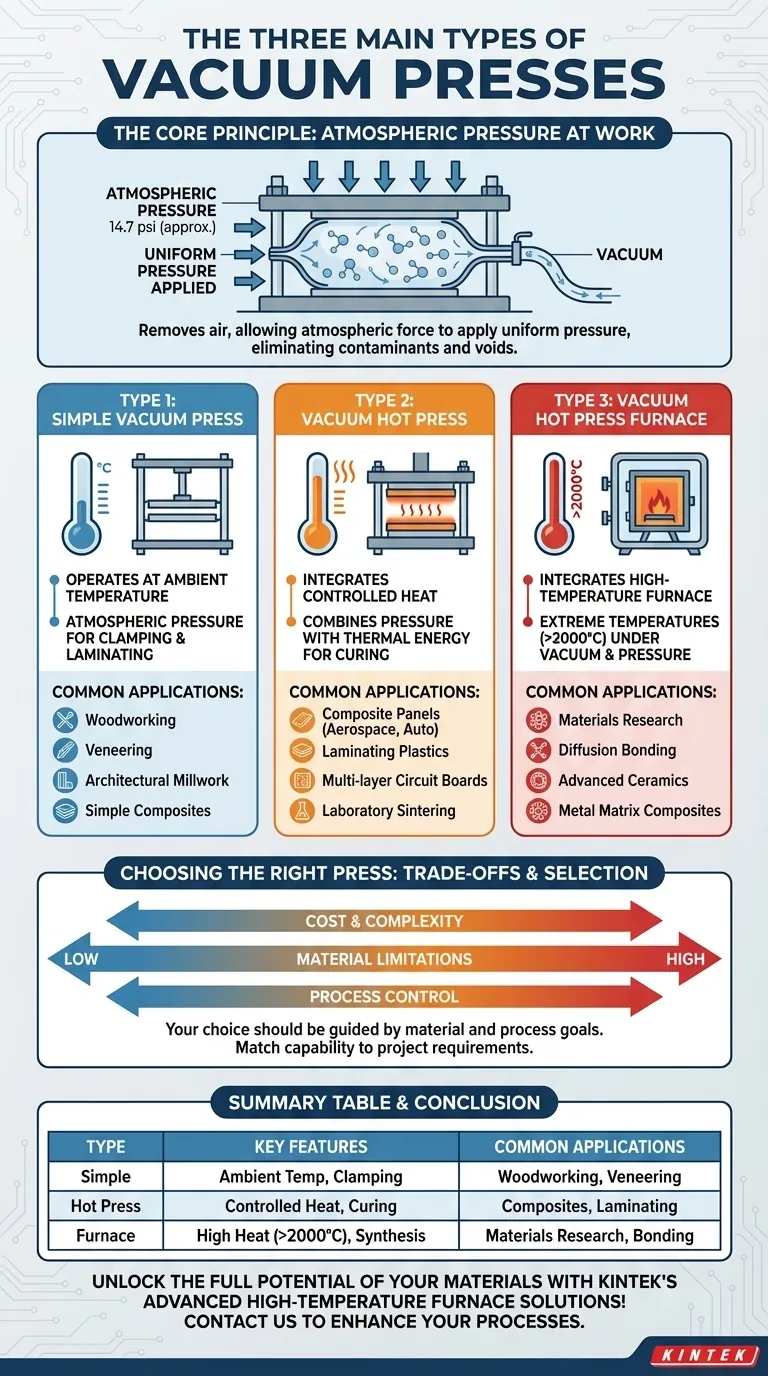

In short, there are three primary types of vacuum presses, each defined by its ability to introduce heat and control the processing environment. These are the Simple Vacuum Press, the Vacuum Hot Press, and the Vacuum Hot Press Furnace. The fundamental difference between them is their level of technological complexity, which directly corresponds to the materials they can process and the applications they serve.

The core distinction between vacuum press types is the integration of heat. A simple press uses only atmospheric pressure at ambient temperature, a hot press adds controlled heat for curing, and a furnace combines high heat with vacuum for advanced material synthesis.

The Core Principle: Atmospheric Pressure at Work

Before comparing the types, it's crucial to understand that a vacuum press doesn't "suck" parts together. It removes the air from a sealed environment, allowing the full force of the outside atmosphere—approximately 14.7 pounds per square inch (or 1 ton per square foot) at sea level—to apply uniform pressure across the entire surface of an object.

Eliminating Air and Contaminants

The primary goal is to remove air trapped between layers of material (plies). This ensures an intimate, void-free bond when laminating veneers, composites, or other substrates.

Creating a Controlled Environment

In more advanced systems, the vacuum chamber also allows for precise control over the processing environment, preventing oxidation and removing volatile compounds released during heating.

Breaking Down the Three Tiers of Vacuum Presses

The classification of a vacuum press is determined by its temperature capabilities. Each tier opens up a new range of materials and industrial processes.

Type 1: The Simple Vacuum Press

This is the most common and accessible type, consisting of a durable, sealable bag (or frame press) and a vacuum generator or pump. It operates entirely at ambient temperature.

Its primary function is clamping and laminating. By removing air, it uses atmospheric pressure to press veneers onto core materials, form curved wood components, or bond simple composites without the need for complex mechanical clamps.

Common Applications: Woodworking, veneering, architectural millwork, and forming simple composite shapes.

Type 2: The Vacuum Hot Press

This system elevates the process by integrating heated platens within the press. It combines the uniform pressure of a vacuum with controlled thermal energy.

This addition of heat is critical for curing thermoset resins found in advanced composites, bonding multi-layer circuit boards, or sintering powdered materials that don't require extreme temperatures. It offers a significant leap in capability over a simple bag press.

Common Applications: Manufacturing composite panels (e.g., aerospace, automotive), laminating plastics, and laboratory-scale sintering.

Type 3: The Vacuum Hot Press Furnace

This represents the most advanced tier of vacuum press technology. It is a highly specialized system that integrates a high-temperature furnace inside a vacuum chamber.

This setup allows for processing materials at extreme temperatures (often exceeding 2000°C) while under vacuum and applied mechanical pressure. This is essential for diffusion bonding dissimilar metals or producing dense, high-purity advanced materials.

Common Applications: Materials science research, producing advanced ceramics, diffusion bonding of exotic alloys, and synthesizing new metal matrix composites.

Understanding the Trade-offs

Choosing a vacuum press involves a direct trade-off between capability, complexity, and cost. Understanding these factors is key to avoiding over-investment or process limitations.

Cost vs. Capability

The cost escalates dramatically with each tier. A simple vacuum press is relatively inexpensive, while a vacuum hot press furnace is a significant capital investment reserved for high-value industrial and research applications.

Process Control vs. Simplicity

A simple bag press is straightforward to operate. As you introduce heat and high-temperature furnace controls, the operational complexity and need for skilled technicians increase substantially.

Material Limitations

Each press is defined by what it can't do. A simple press cannot cure heat-activated resins. A vacuum hot press cannot reach the temperatures needed for creating advanced ceramics or superalloys. The material and process requirements dictate the necessary technology.

Selecting the Right Press for Your Application

Your choice should be guided entirely by your material and process goals.

- If your primary focus is woodworking, veneering, or forming simple shapes at room temperature: The Simple Vacuum Press is the correct and most cost-effective tool.

- If your primary focus is curing advanced composites, laminating multi-layer electronics, or performing low-temperature sintering: You require the combined heat and pressure capabilities of a Vacuum Hot Press.

- If your primary focus is materials research, diffusion bonding, or creating advanced ceramics and alloys: The high-temperature, highly controlled environment of a Vacuum Hot Press Furnace is non-negotiable.

Ultimately, matching the press's capabilities to your project's specific temperature and pressure requirements is the key to a successful outcome.

Summary Table:

| Type | Key Features | Common Applications |

|---|---|---|

| Simple Vacuum Press | Operates at ambient temperature, uses atmospheric pressure for clamping | Woodworking, veneering, architectural millwork |

| Vacuum Hot Press | Adds controlled heat for curing resins and sintering | Composite panels, laminating plastics, laboratory sintering |

| Vacuum Hot Press Furnace | Combines high heat (>2000°C), vacuum, and pressure for synthesis | Materials research, diffusion bonding, advanced ceramics |

Unlock the full potential of your materials with KINTEK's advanced high-temperature furnace solutions! Whether you're in woodworking, composite manufacturing, or cutting-edge materials research, our expertise in R&D and in-house manufacturing ensures you get the perfect vacuum press for your needs. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by deep customization capabilities to meet your unique experimental requirements. Contact us today to discuss how we can enhance your processes and drive innovation in your lab!

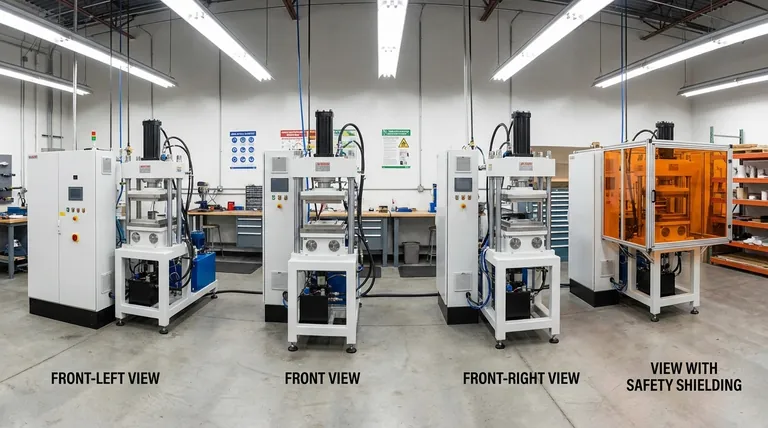

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- What is a vacuum hot press furnace? Unlock Superior Material Performance