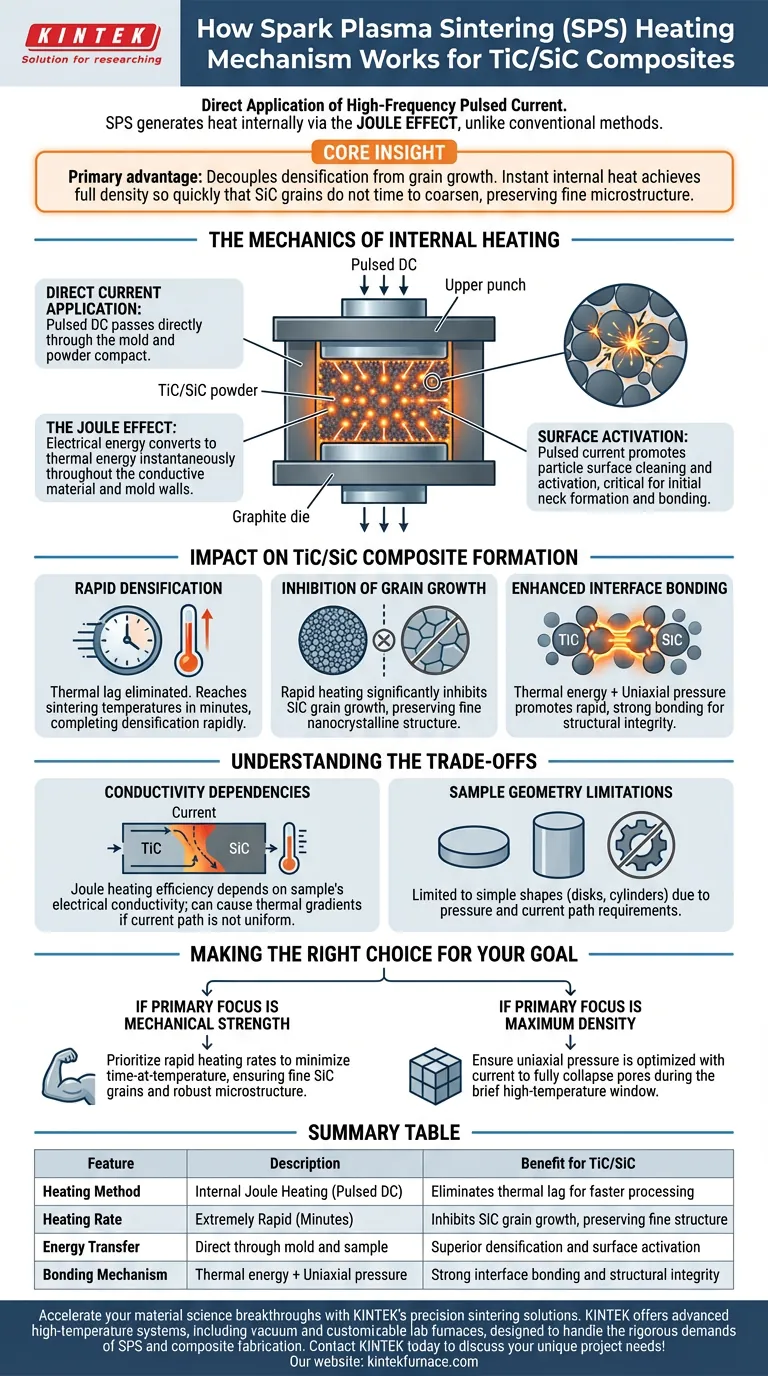

The heating mechanism of Spark Plasma Sintering (SPS) is defined by the direct application of high-frequency pulsed current through the graphite mold and the composite sample itself. Unlike conventional methods that rely on external heating elements, SPS generates heat internally via the Joule effect. This allows for extremely rapid heating rates that facilitate the consolidation of Titanium Carbide (TiC) and Silicon Carbide (SiC) powders.

Core Insight: The primary advantage of SPS lies in its ability to decouple densification from grain growth. By generating heat internally and instantaneously, the process achieves full density so quickly that the SiC grains do not have time to coarsen, preserving the material's fine microstructure.

The Mechanics of Internal Heating

Direct Current Application

In the SPS process, a pulsed Direct Current (DC) is passed directly through the graphite die and the TiC/SiC powder compact.

The energy is not radiated from the outside in; it is conducted through the assembly.

The Joule Effect

As the current encounters resistance within the mold and the powder particles, electrical energy is converted directly into thermal energy.

This phenomenon, known as Joule heating, occurs instantaneously throughout the volume of the material (assuming the material is conductive) and the mold walls.

Surface Activation

The "on-off" nature of the pulsed current creates specific conditions at the contact points between powder particles.

While the generation of bulk plasma is debated, the current promotes particle surface cleaning and activation, which is critical for the initial stages of neck formation and bonding.

Impact on TiC/SiC Composite Formation

Rapid Densification

Because the heat is generated internally, the thermal lag associated with conventional furnaces is eliminated.

This allows the TiC/SiC composite to reach sintering temperatures in minutes rather than hours, completing densification in a very short timeframe.

Inhibition of Grain Growth

Long exposure to high temperatures typically causes Silicon Carbide (SiC) grains to grow larger, which can reduce the strength of the final composite.

The rapid heating rate of SPS significantly inhibits SiC grain growth, preserving the desirable fine or nanocrystalline structure of the material.

Enhanced Interface Bonding

SPS combines this thermal energy with uniaxial mechanical pressure.

This combination promotes rapid and strong interface bonding between the TiC matrix and the SiC reinforcements, ensuring the structural integrity of the composite.

Understanding the Trade-offs

Conductivity Dependencies

The efficiency of the Joule heating depends heavily on the electrical conductivity of the sample.

Since TiC and SiC have different electrical properties, thermal gradients can occasionally occur within the sample if the current path is not uniform.

Sample Geometry Limitations

Because the current must pass through the mold and sample under pressure, complex geometries are difficult to achieve.

SPS is generally limited to simple shapes like disks or cylinders, requiring post-sintering machining for complex parts.

Making the Right Choice for Your Goal

When utilizing SPS for TiC/SiC composites, adjust your parameters based on your specific material requirements:

- If your primary focus is mechanical strength: Prioritize rapid heating rates to minimize time-at-temperature, ensuring the SiC grains remain fine and the microstructure robust.

- If your primary focus is maximum density: Ensure the uniaxial pressure is optimized alongside the current to fully collapse pores during the brief high-temperature window.

SPS offers a unique pathway to sinter difficult-to-process composites like TiC/SiC by using speed and internal energy to bypass the thermal limitations of traditional ceramics processing.

Summary Table:

| Feature | Description | Benefit for TiC/SiC |

|---|---|---|

| Heating Method | Internal Joule Heating (Pulsed DC) | Eliminates thermal lag for faster processing |

| Heating Rate | Extremely Rapid (Minutes) | Inhibits SiC grain growth, preserving fine structure |

| Energy Transfer | Direct through mold and sample | Superior densification and surface activation |

| Bonding Mechanism | Thermal energy + Uniaxial pressure | Strong interface bonding and structural integrity |

Accelerate your material science breakthroughs with KINTEK's precision sintering solutions. Backed by expert R&D and manufacturing, KINTEK offers advanced high-temperature systems, including vacuum and customizable lab furnaces, designed to handle the rigorous demands of Spark Plasma Sintering and composite fabrication. Whether you are aiming for maximum density or refined microstructures in TiC/SiC composites, our team provides the specialized tools to optimize your research and production outcomes. Contact KINTEK today to discuss your unique project needs!

Visual Guide

References

- Advancing Technology and Addressing Toxicity: The Dual Impacts of Rare Earth Elements on Materials and the Environment. DOI: 10.37933/nipes/7.2.2025.19

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does hot pressing differ from ordinary cold pressing and sintering? Unlock Superior Material Performance

- What types of shapes can be manufactured using vacuum hot pressing? From Simple Blocks to Complex Components

- What are the temperature-based classifications for vacuum hot pressing sintering furnaces? Choose the Right Furnace for Your Materials

- What are the mold configuration requirements for sintering non-conductive powders in FAST? Expert Setup Guide

- What components are used in hot press furnaces to apply pressure? Essential Parts for Precise High-Temp Compression

- How does hot pressing compare to hot isostatic pressing (HIP)? Choose the Right Process for Your Materials

- Why is a high vacuum environment essential during hot press sintering? Achieve High-Strength Aluminum Composites

- What are the primary advantages of FAST/SPS in Ti-6Al-4V recycling? Transform Efficiency with Solid-State Sintering